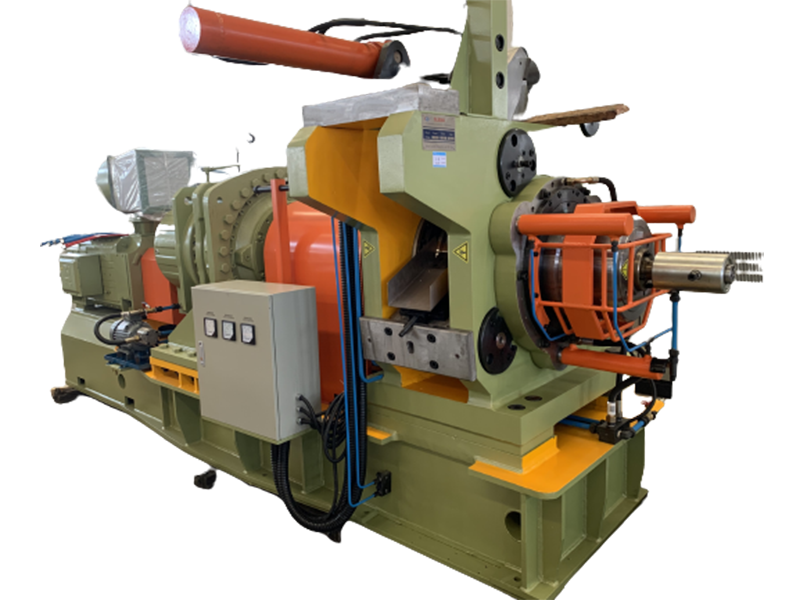

TLJ500 Continuous Extrusion Machine for Copper Profile&Rod

1. Status in the industry: World leader, sales account for 50% of the world's totally in continuous extrusion industry.

2. Machine feature: Energy saving of about 10% without reducing production capacity; Mechanical locking of extrusion tooling to ensure stability of extrusion conditions; Upgrade the brand of the gearbox; Upgrade electrical control system, monitoring production conditions, add remote module for maintenance All the data monitoring and remote maintenance support.

3 . R&D: Separate R&D team. Improve and develop the machine annually. Have an independent laboratory to conduct on-site product testing based on the special materials provided by the customer.

4. Aftersales service: 30 maintenance engineers travel around the world for machine installation and maintenance frequently. They can reach to customer‘s plant at very short time, Provide online support or remote control for 24 hours.

Copper Bar Conform MachineCopper Bar Continuous Extrusion MachineConform Machine for Copper BarContinuous Extruder

Email

More