In the factory, the most troublesome thing is the capacity problem. If the work is slow, the work is small, and the quality is not stable, then the customers and the boss will be anxious, and everyone will worry. Is there a way to make batches of products quickly and stably? Of course there is! This is the "continuous extrusion" we are going to introduce.

Continuous extrusion, to put it simply, is to heat the metal and squeeze it out of the mold little by little like squeezing toothpaste to form the shape we want. The entire production process is non-stop, wasteless, and very efficient, which is very suitable for industries that require mass production. For example, cable factories, aluminum products factories, copper strip and copper wire factories, many of them are using this technology.

So how powerful is it? For example, a Continuous Extrusion Machine can work 24 hours a day and continuously produce hundreds of kilograms or even tons of metal products. And there is no need for repeated heating and cutting, which reduces manual operation and costs, and saves energy consumption. The products produced by extrusion are uniform in size, smooth in surface, and more convenient to use.

Konform is a company that specializes in producing Continuous Extrusion Machine and has been in this business for many years. The Continuous Extrusion Machine we designed is stable, durable, easy to operate, and has a complete range of models, which can almost meet the different needs of various metal processing companies.

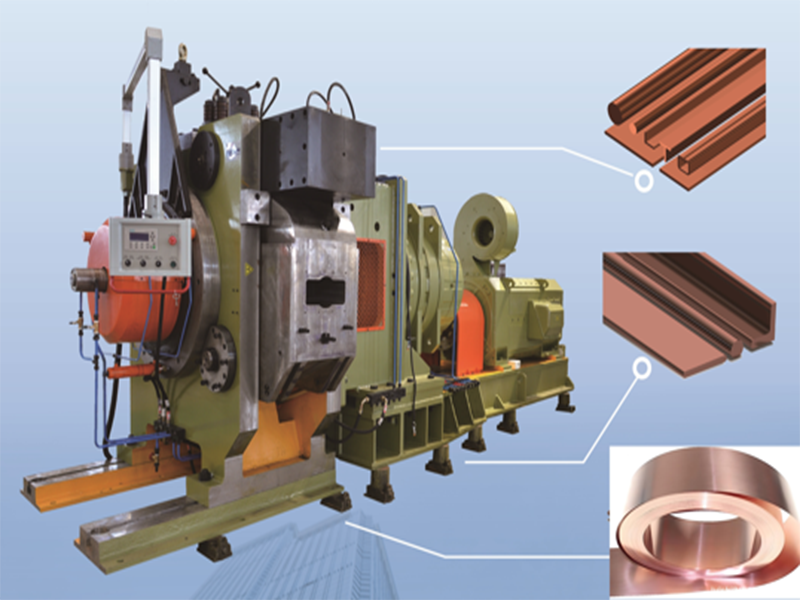

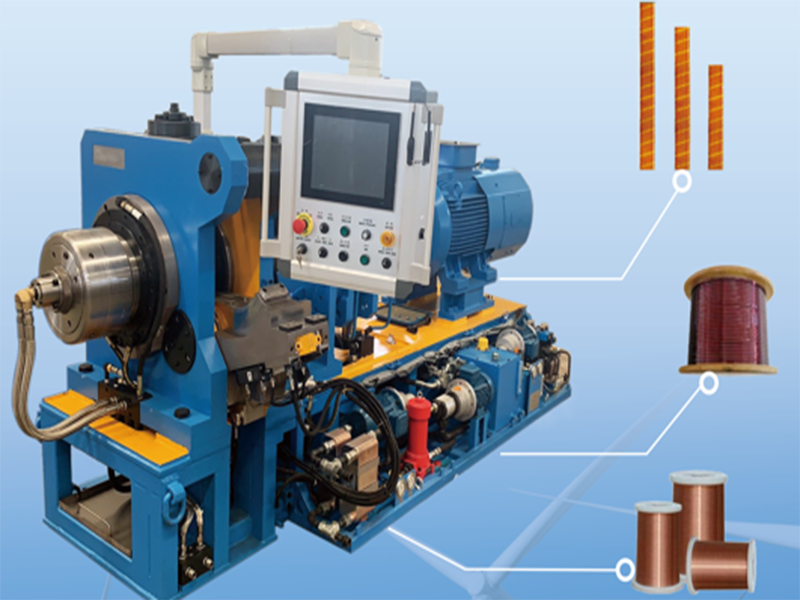

For example, our TLJ300 Continuous Extrusion Machine for Copper Wire is very suitable for copper products, whether it is flat wire, conductor or special-shaped material, with fast speed and good effect; and TLJ630 Continuous Extrusion Machine for Copper Strip has high processing strength, and the pressed products are dense and strong.

Konform has a large modern factory, equipped with laser cutting, CNC machining, automatic assembly and other equipment in the workshop. We independently process and produce key parts such as extrusion wheels and molds, and strictly control them. Each metal extrusion machine will undergo a complete test run before leaving the factory to help customers check the problems that may be encountered during the operation in advance, debug the metal extrusion machine in advance, so that customers can put the product into production as soon as they receive it.

We have many domestic and foreign customers who say that after using our metal extrusion machine, the workers are relaxed, the orders are completed faster, and customer satisfaction is also improved. If you also want to use our continuous extrusion equipment to improve production efficiency, please leave a message to tell us what products you make and what problems you encounter. We will choose the most suitable metal extrusion machine for you from the perspective of a professional manufacturer! You are also welcome to visit the factory and experience the charm of continuous extrusion on site!