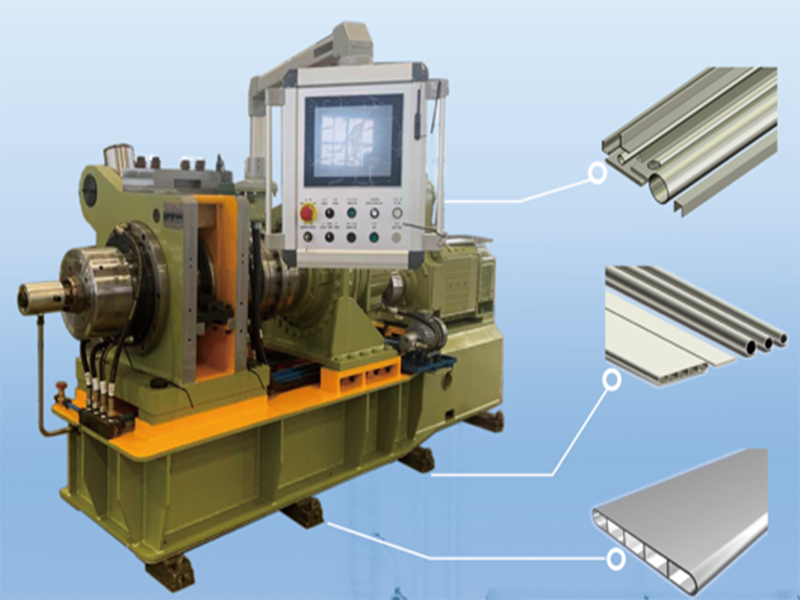

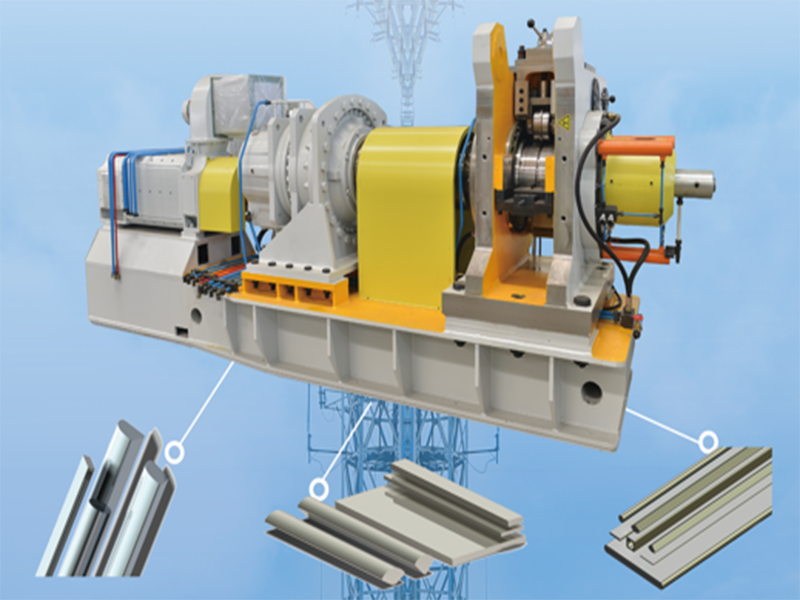

LLJ 400 Continuous Extrusion Production Line for Aluminum Busbar&Strip

1. Continuous extrusion machine for aluminum busbar accounting for 50% of worldwide sales in the continuous extrusion sector.

2. Continuous extrusion machine for aluminum busbar is designed for energy efficiency, saving about 10% in energy consumption while maintaining production capacity. It features mechanical locking of extrusion tooling for stable extrusion conditions and comes with an upgraded gearbox and electrical control system. Additionally, it includes data monitoring and remote maintenance support for real-time production condition monitoring.

3. With a dedicated R&D team, continuous extrusion machine for aluminum busbar is improved and developed annually. The independent laboratory conducts on-site testing using customer-specific materials to ensure optimal performance.

4. For after-sales support, 30 experienced engineers provide global installation and maintenance services of aluminum plate forming machine. They can quickly reach customer plants and offer 24/7 online support and remote troubleshooting.

Aluminum continuous extrusion machineAluminum Sheet Making MachineAluminum plate forming machineContinuous Extrusion Machine for Aluminum BusbarContinuous Extrusion Production Line

Email

More