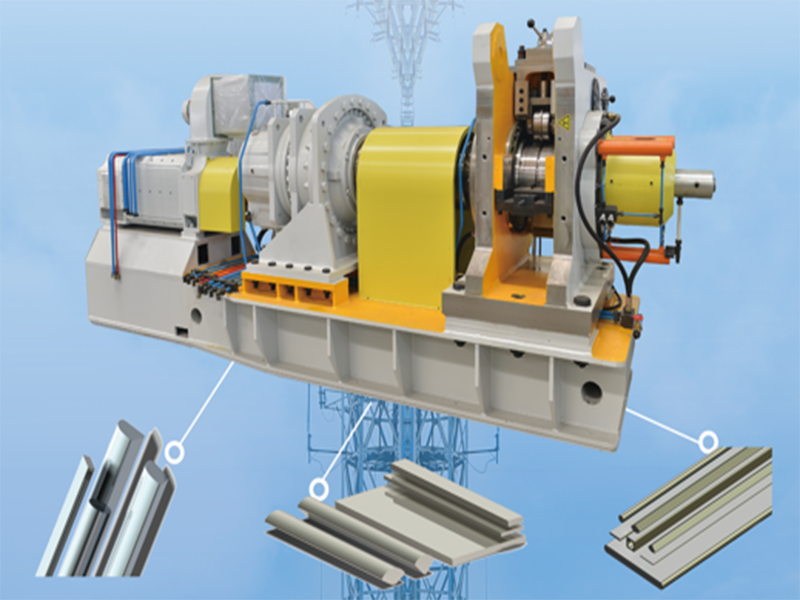

Introduction of aluminum solid conductor continuous extrusion machine:

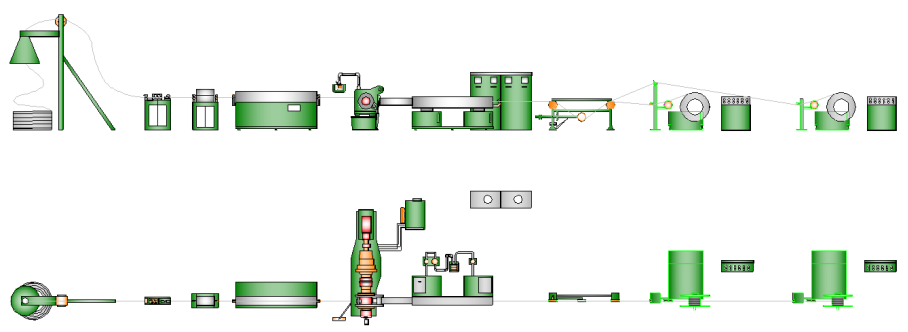

Aluminum solid conductor continuous extrusion machine is suitable for the development of large-size aluminum and aluminum alloy busbars, cable trays and other flat profiles. Aluminum solid conductor continuous extrusion machine adopts advanced continuous extrusion molding technology. Through friction drive and shear heating principles, it can directly extrude aluminum rods into flat or special-shaped conductive busbar products with the required cross-section, which meets the requirements of high conductivity and high current carrying capacity busbars in multiple fields such as power, rail transit, and new energy.

Features of aluminum solid conductor extrusion line:

1. The main machine of aluminum solid conductor extrusion line adopts high-rigidity cast steel structure, which can ensure that it can still operate stably under high-speed extrusion.

2. Aluminum solid conductor extrusion line adopts air cooling + water cooling combination cooling, which can keep the aluminum busbar stable during the forming process to avoid deformation.

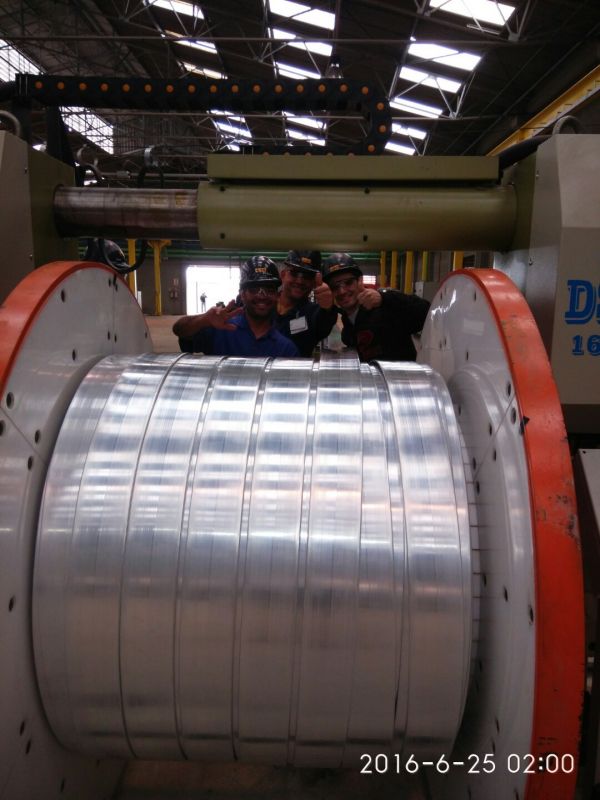

3. Aluminum solid conductor extrusion line supports automatic cut-to-length cutting and neat winding, which can make the busbar end neatly and facilitate subsequent packaging and transportation.

Specifications of continuous extrusion machine for aluminum busbar&solid conductor:

| Model | LLJ350 | LLJ400 |

| Nominal diameter of extrusion wheel (mm) | 350 | 400 |

| product category | Sector/shaped conductor | Aluminium busbar |

| Main motor power (kW) | 160 | 250 |

| Aluminum rod diameter (mm) | 2×9.5/15 | 2×15/15 |

| Maximum width of product (mm) | —— | 170 |

| Product cross-sectional area (mm2) | 25~300 | 75~2000 |

| Productivity (kg/h) | 260 | 600/900 |

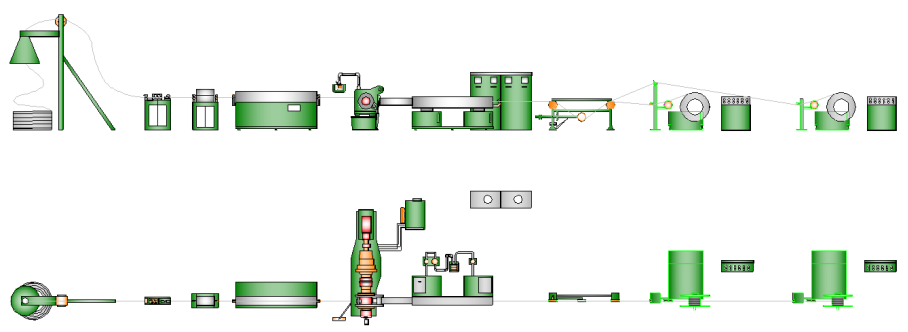

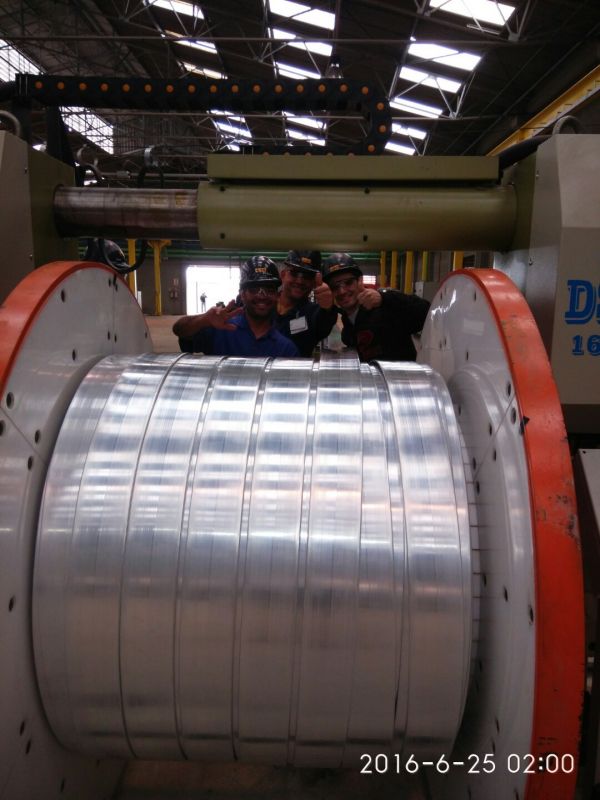

Continuous extrusion production line for aluminum busbar and solid conductor:

Use of continuous extrusion machine for aluminum busbar:

Continuous extrusion machine for aluminum busbar is mainly used to produce aluminum or aluminum alloy busbars with high conductivity and high dimensional stability, such as substation busbars, low-voltage switchgear busbars, reactor terminal blocks, capacitor cabinet contact busbars, etc. Our continuous extrusion machine for aluminum busbar can meet the high current and low loss requirements of the main current conductors in the power supply systems of subways and high-speed railways. Continuous extrusion machine for aluminum busbar is also suitable for aluminum conductive connection components in photovoltaic inverters, energy storage systems, wind energy conversion equipment, etc.

Notes on aluminum solid conductor continuous extrusion machine:

Before the aluminum conductor continuous extrusion line is officially used, it must be debugged by professionals according to the equipment installation drawings and instructions. Before the first operation of the aluminum solid conductor extrusion line, all cables, cooling pipes, and air pressure interfaces must be checked. Before starting the continuous extrusion machine for aluminum busbar each time, check the lubricating oil level, coolant circulation, etc. During operation, pay attention to whether the temperature and pressure curves are within the set range; clean the mold after shutdown and drain the cooling system.

Machine development milestone of dalian konform:

Year of 2004 | Dalian Konform developed LLJ300A continuous extrusion machine for Microchannel aluminum tube first in China |

Year of 2005 | Dalian Konform developed TLJ400 continuous extrusion machine for copper/aluminum busbar first in China |

Year of 2008 | Dalian Konform developed TLJ630 continuous extrusion machine for copper strip first in China |

Year of 2009 | Dalian Konform developed TLJ500 continuous extrusion machine for copper busbar first in China |

Year of 2010 | Dalian Konform developed LLJ300B continuous extrusion machine for aluminum tube first in China |

Year of 2015 | Dalian Konform developed continuous casting and extrusion machine for aluminum first in China |

Year of 2016 | Dalian Konform developed SSLB500 continuous sheathing machine for high voltage cable sheath in the world |

Year of 2018 | Dalian Konform developed U type continuous extrusion machine for copper strip first in China |

Year of 2019 | Dalian Konform developed 300H high speed continuous extrusion machine for copper&aluminum in the world |

Year of 2022 | Dalian Konform developed TLJ800U continuous extrusion machine for copper strip first in the world |

About us:

Founded in 1993, Dalian Konform Technology co., ltd. is a global leading supplier of continuous extrusion technology and equipment. Dalian Konform has developed 24 different models of equipment in three major product categories (continuous extrusion, continuous cladding and continuous sheathing of copper and aluminum).