Product introduction of Pipe Continuous Rotary Extrusion Line:

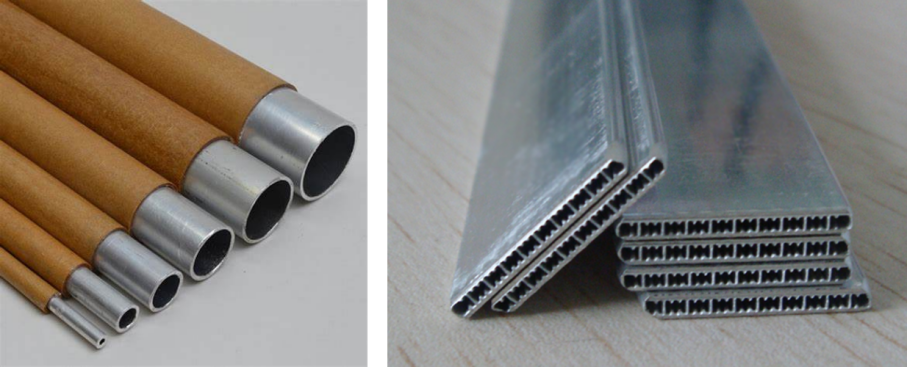

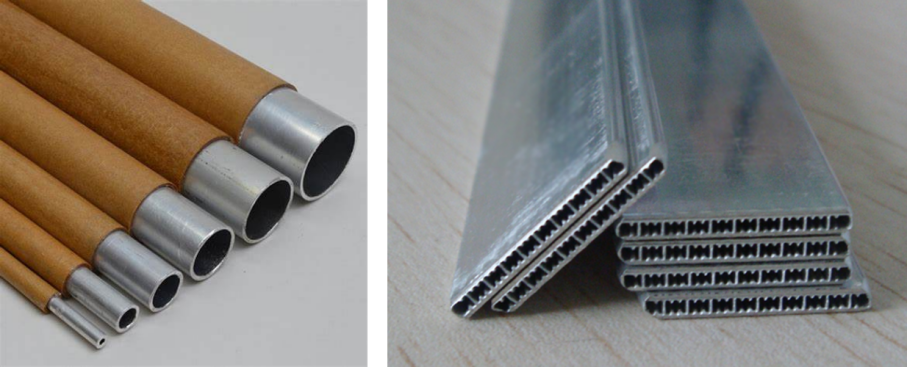

Pipe Continuous Rotary Extrusion Line is a highly efficient equipment specially used for producing copper or aluminum alloy pipes. Through the continuous rotary extrusion process, the metal material is directly extruded into a tube. The use of Continuous Rotary Extrusion Process does not require traditional heating and multiple processing, saving time and cost. Pipe Rotary Extrusion Line has stable operation and good molding effect. The produced pipes are uniform in size and smooth in surface. They are widely used in air conditioning pipes, heat dissipation pipes, power threading pipes and other fields.

Working principle of Pipe Rotary Extrusion Line:

The working principle of Pipe Rotary Extrusion Line is to continuously push a metal rod forward through the extrusion wheel in Pipe Rotary Extrusion Line, and then pass through a special mold to press the raw material into a hollow tube. This whole process does not require heating the metal to melt, which is both energy-saving and efficient. Pipe Rotary Extrusion Line can work continuously and is very suitable for mass production of various copper tubes, aluminum tubes and other metal tubes.

Specifications of Continuous Rotary Extrusion Line for Tube:

| Model | LLJ300 | LLJ300B | LLJ300H |

| Nominal diameter of extrusion wheel (mm) | 290 | 310 | 290 |

| Main motor power (kW) | 110 | 132 | 110 |

| Aluminum rod diameter (mm) | 9.5 | 12 | 9.5 |

| Diameter of aluminum round pipe (mm) | 5~20 | 5~20 | 5~20 |

| Width of flat aluminum tube (mm) | - | ≤40 | ≤40 |

| Productivity (kg/h) | 160 | 190 round/140 flat | 240 |

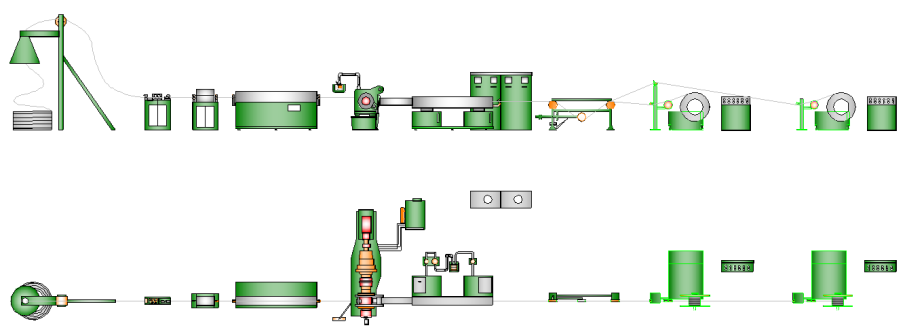

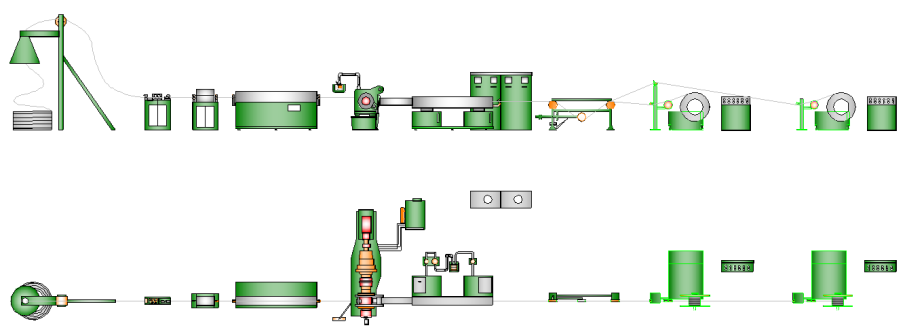

Line layout of the Continuous Rotary Extrusion Process:

Production process of Pipe Continuous Rotary Extrusion Line:

The production process of Konform factory is strictly orderly. Starting from the storage of raw materials, every step is strictly controlled. The raw materials are first inspected by quality inspectors, and then enter the processing stage after passing the inspection. During the processing, we use advanced CNC equipment and automated assembly lines to ensure the accuracy and consistency of each component. Then the equipment is assembled, debugged and tested for multiple rounds to ensure that the Pipe Continuous Rotary Extrusion Line machine runs smoothly and meets the performance standards. Each process is managed by a dedicated person, and the whole process is recorded to ensure traceability and management, ensuring that every Continuous Rotary Extrusion Process shipped is of reliable quality and customers are assured.

About us:

Dalian Konform is an enterprise focusing on the research and development and manufacturing of metal extrusion equipment, with many years of industry experience and a mature technical team. The company integrates R&D, production, sales and service. The main products cover continuous extrusion equipment for copper, aluminum and their alloys, which are widely used in power, cable, hardware, electronics and other fields. We always adhere to technological innovation, have a number of independent patents, and have passed ISO9001 quality management system certification and EU CE certification. Our products are not only sold well throughout the country, but also exported to many countries and regions overseas, and are deeply trusted by customers. We are committed to providing customers with efficient, stable and energy-saving equipment solutions. Welcome to cooperate and seek common development.