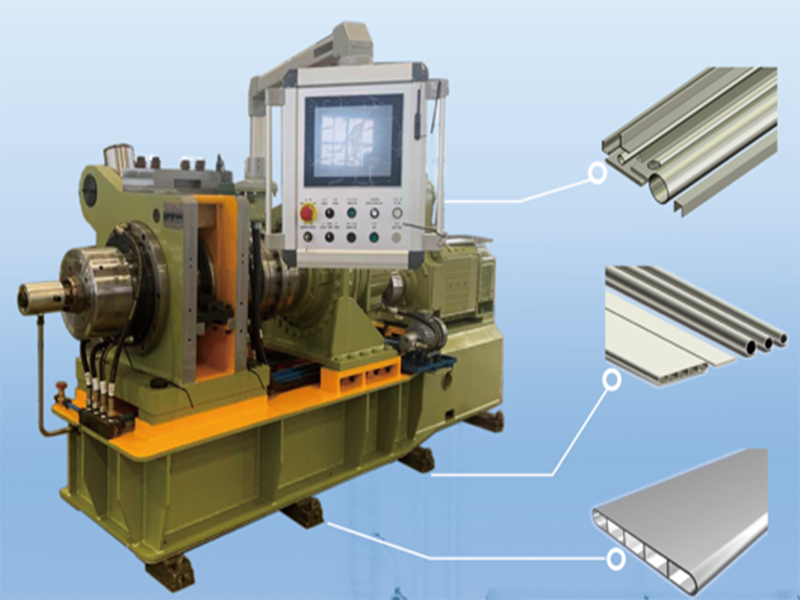

Main uses of the LLJ300B Continuous Extrusion Machine for Aluminum Tube:

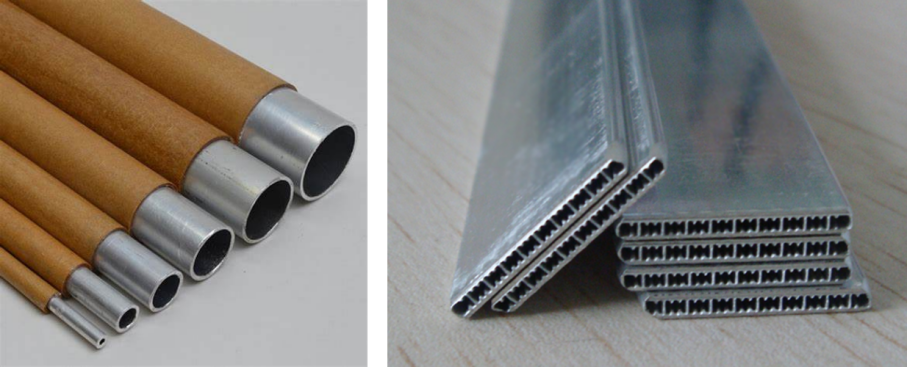

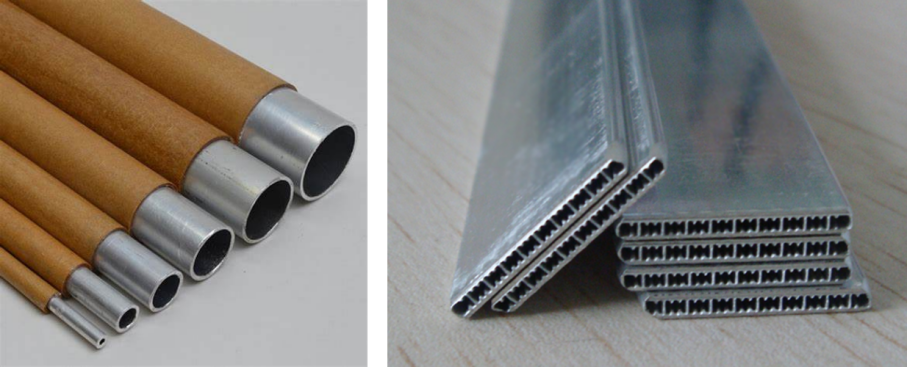

We specialize in the production of high-quality aluminum tube rotary extruder used in the evaporators of refrigerators and freezers, as well as precision-engineered multi-hole tubes widely applied in automotive air conditioning systems and intercoolers. Our aluminum tube rotary extruder range also includes harmonica tubes and other customized extruded profiles, designed to meet the specific heat exchange and performance requirements of different industries. With advanced manufacturing technology and strict quality control, we ensure consistent performance, excellent thermal conductivity, and durability in all our tubing products.

Specifications of Rotary Extrusion Machine for Aluminum Hollow Tube:

| Model | LLJ300 | LLJ300B |

| Nominal diameter of extrusion wheel (mm) | 290 | 310 |

| Main motor power (kW) | 110 | 132 |

| Aluminum rod diameter (mm) | 9.5 | 12 |

| Diameter of aluminum round pipe (mm) | 5~20 | 5~20 |

| Width of flat aluminum tube (mm) | - | ≤40 |

| Productivity (kg/h) | 160 | 190 round/140 flat |

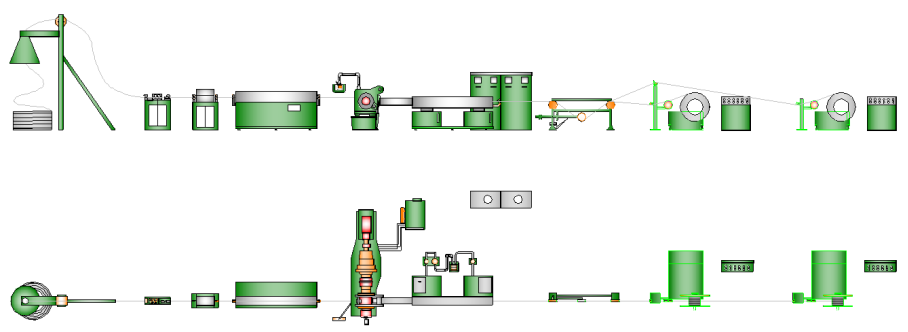

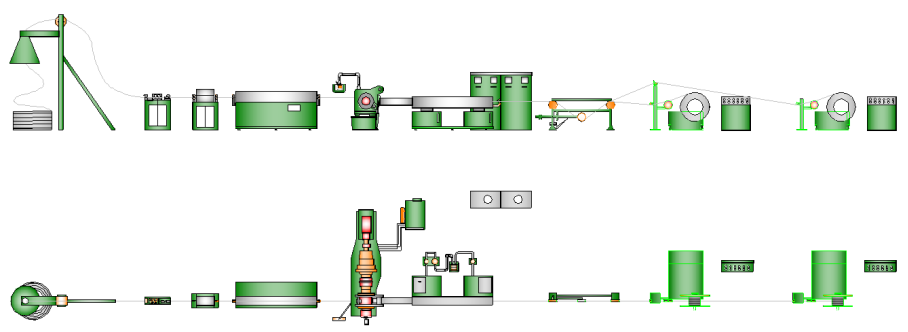

Production Line layout of the Continuous Extrusion Machine for Aluminum Tube:

FAQ:

Q1: How is Aluminum hollow tube processing equipment's production efficiency?

A1: Aluminum hollow tube processing equipment's continuous extrusion process has the advantage of high efficiency, which can achieve stable and continuous aluminum tube production, with a maximum speed of tens of meters per minute, suitable for mass production needs.

Q2: Does Continuous Extrusion Machine for Aluminum Tube support customized tube types?

A2: Yes. Aluminum tube rotary extruder can customize molds according to customer needs and produce round tubes, porous tubes, special-shaped tubes, etc. of different specifications, which are widely used in air conditioners, heat exchangers and other fields.

Konform Technology

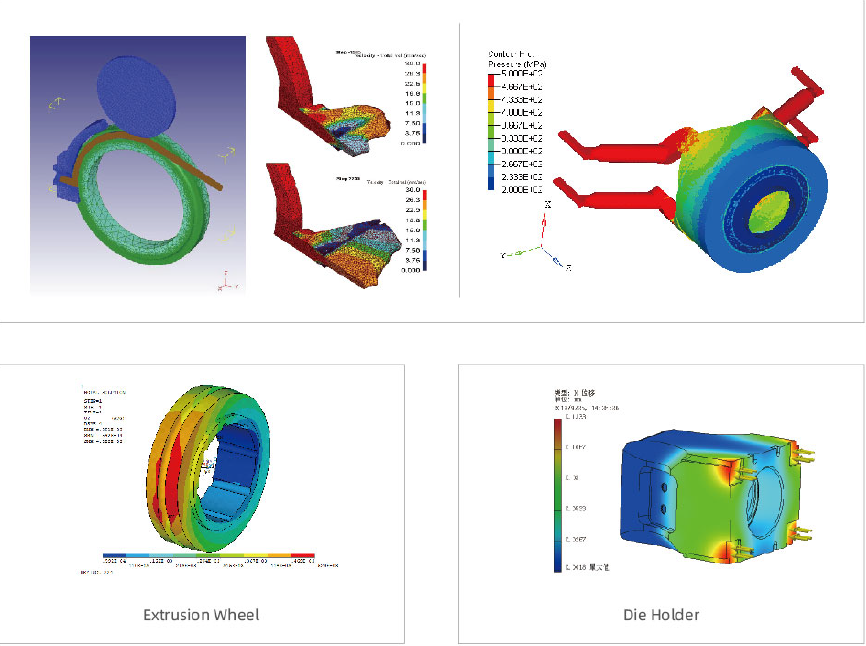

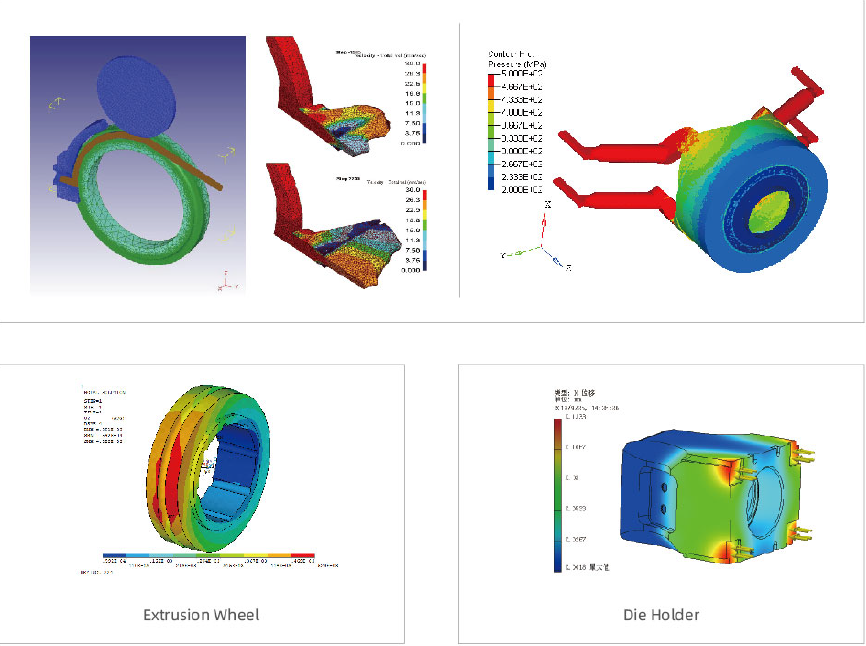

We determine all essential process parameters based on the latest advancements in heat treatment of nonferrous metals. By utilizing advanced numerical simulation tools for plastic forming, we evaluate the flow velocity, stress distribution, and temperature characteristics within the deformation zone of the continuous extrusion machine for aluminum tubes. This allows us to accurately assess the required load on both equipment and tooling, ensuring design reliability. The system identifies optimal settings for key process variables—including extrusion wheel, billet material, chamber structure, die configuration, and cooling parameters—tailored to each stage of operation.

Our advantages of Aluminum tube rotary extruder:

Advanced processing methods and strict processing technology ensure the excellent quality and durable life of Konform equipment. The aluminum hollow tube processing equipment is fully debugged before leaving the factory, and there is absolutely no flaw in the customer.

We have established a strict supply chain management system of aluminum hollow tube processing equipment: raw materials and supporting components are provided by well-known domestic and foreign companies, and electrical components are all made of first-class brands at home and abroad.

Supported by an ERP system that integrates sales, R&D, manufacturing, procurement, and logistics, we are able to greatly shorten the manufacturing cycle. Through transformation from "order-design" to "order-configuration" , we can now promptly respond to our customer's diversified requirements and quickly deliver orders. We developed konform machine for copper back 30 years ago.

Our spare parts:

Tooling accessories and molds (extrusion wheel, cavity, mold, guide plate, compaction wheel...): using high-quality steel at home and abroad, relying on the forging advantages of Dalian Heavy Industry Base, using the company's unique heat treatment process and vacuum furnace to ensure accessories Long service life, using high-quality brand machining centers, CNC machine tools and electrical processing equipment to ensure the accuracy and quality of accessories.