Product introduction of Aluminum Wire Rotary Extrusion Machine:

The Aluminum Wire Rotary Extrusion Machine we produce is a device specially used to process aluminum bars into aluminum wires. It is easy to operate and highly efficient. Aluminum wire continuous extrusion machine continuously extrude aluminum into the required wire shape by rotating. The finished product has a smooth surface and uniform size. Continuous Rotary Extruder Aluminum Wire is suitable for industries such as wires and cables, electronic components, and is particularly suitable for factories that require large-scale, high-precision aluminum wire production.

Continuous Rotary Extruder Aluminum Wire is mainly used for:

Aluminum wire continuous extrusion machine is mainly used to produce aluminum wires of various specifications, and is widely used in the fields of wires and cables, power conductors, electronic components, and automotive accessories. Aluminum wire continuous extrusion machine is suitable for processing pure aluminum or aluminum alloy materials, and can achieve continuous and stable extrusion production, which can meet the needs of large-scale, high-quality aluminum wire manufacturing.

Specifications of Continuous Extrusion Machine for Aluminum Round Wire:

| Model | LLJ300 | LLJ300H | LLJ350 |

| Nominal diameter of extrusion wheel (mm) | 300 | 300 | 350 |

| product category | Aluminum flat wire | Aluminum flat wire | Sector/shaped conductor |

| Main motor power (kW) | 110 | 110 | 160 |

| Aluminum rod diameter (mm) | 9.5 | 9.5 | 2×9.5/15 |

| Maximum width of product (mm) | 30 | 30 | —— |

| Product cross-sectional area (mm2) | 5~200 | 5~200 | 25~300 |

| Productivity (kg/h) | 160 | 280 | 260 |

Correct use of Continuous Rotary Extruder Aluminum Wire:

Check the status: Check whether Continuous Rotary Extruder Aluminum Wire is clean, whether the lubricating oil is sufficient, and whether the power supply and control system are normal before starting.

Install aluminum rod raw materials: Put aluminum rods that meet the specifications into the feeding system of Aluminum Wire Rotary Extrusion Machine correctly to ensure accurate positioning and no jamming.

Set parameters: Set relevant parameters such as temperature, speed, pressure, etc. according to product requirements to ensure stable production.

Start equipment operation: Start Aluminum Wire Rotary Extrusion Machine according to the operating procedures, observe whether the extrusion is smooth, and confirm whether the finished product size is qualified.

Process monitoring: Pay attention to the operating status of the equipment and the quality of the aluminum wire at any time during operation, and stop the machine in time if abnormalities are found.

Wire collection and sorting: Reel or cut the extruded aluminum wire as required, and mark and record it.

Shutdown and maintenance: Clean up the equipment residue after shutdown, turn off the power, perform daily maintenance on key parts, and extend the service life of the equipment.

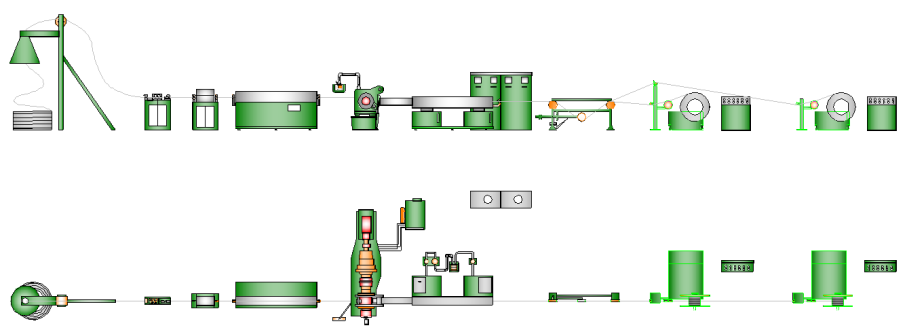

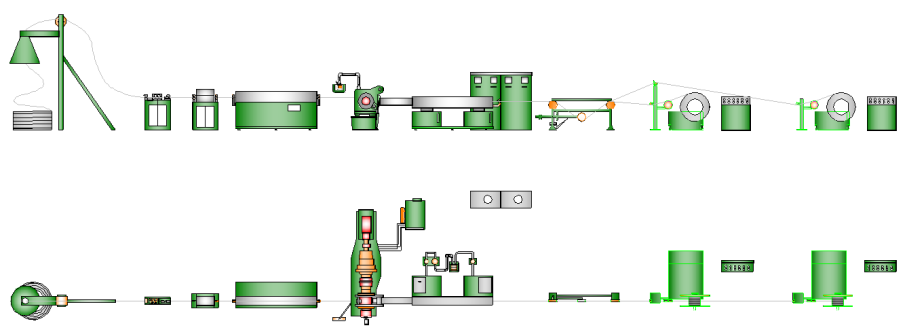

Line layout of the Continuous Extrusion Machine for Aluminum Round Wire:

Our advantage:

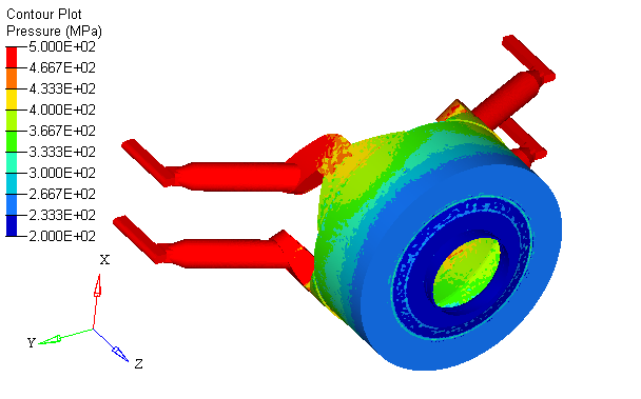

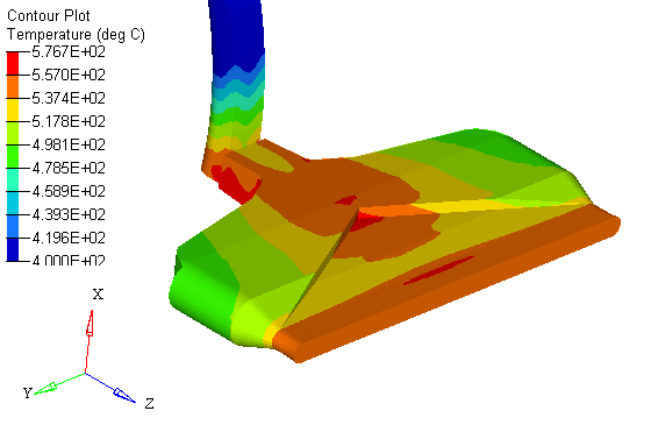

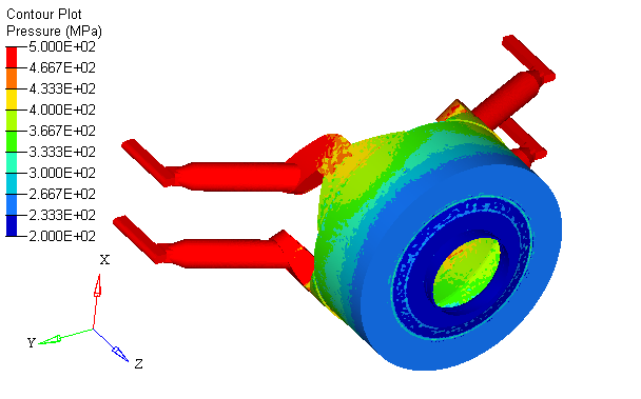

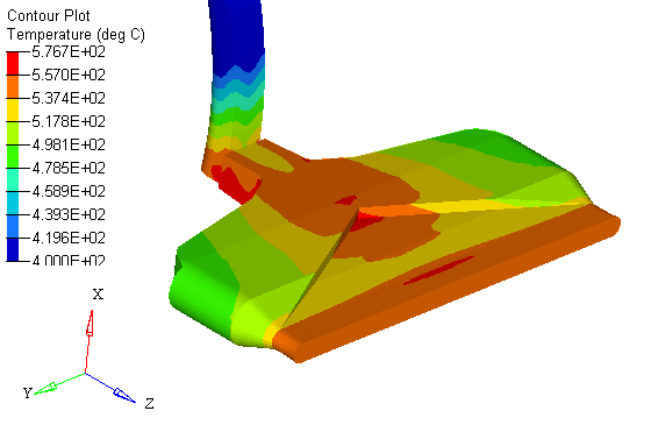

Technological innovation has always been the driving force behind our progress. We use various advanced technological means to conduct in-depth and thorough research on the continuous extrusion process.

About us:

Dalian Konform is a modern factory specializing in the manufacture of continuous extrusion equipment, with rich production experience and mature technical system. The company has long been committed to providing efficient equipment support for the processing of copper, aluminum and alloy materials. With stable product quality and fast after-sales response, we have accumulated a wide range of customer bases at home and abroad and become a trustworthy partner in the industry.