Aluminum continuous extrusion machine main uses of:

The main purpose of aluminum continuous extrusion machine is to process aluminum bars or aluminum wires into aluminum strips or special-shaped aluminum materials of various specifications through continuous extrusion process. Aluminum continuous extrusion machine is widely used in busbar systems and other fields in the power industry. Through continuous extrusion without intermediate heating, aluminum sheet making machine can achieve efficient, energy-saving and continuous forming production.

Specifications of aluminum continuous extrusion machine:

| Model | LLJ400 |

| Nominal diameter of extrusion wheel (mm) | 400 |

| product category | Aluminium platoon |

| Main motor power (kW) | 250 |

| Aluminum rod diameter (mm) | 2×15/15 |

| Maximum width of product (mm) | 170 |

| Product cross-sectional area (mm2) | 75~2000 |

| Productivity (kg/h) | 600/900 |

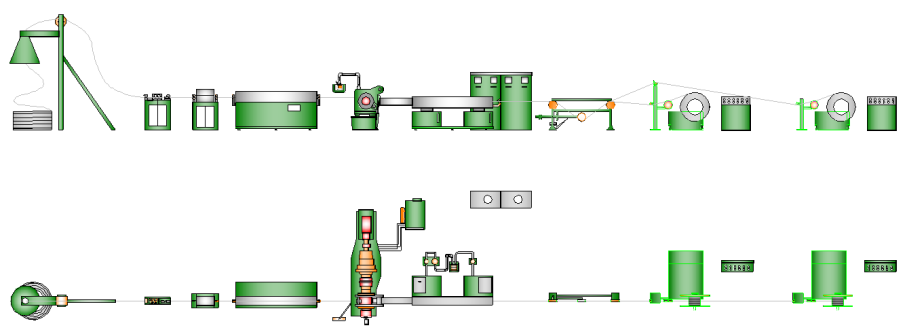

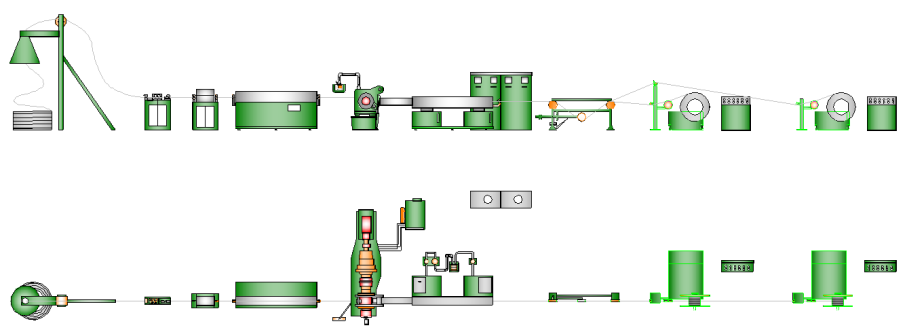

Layout of Aluminum plate forming machine:

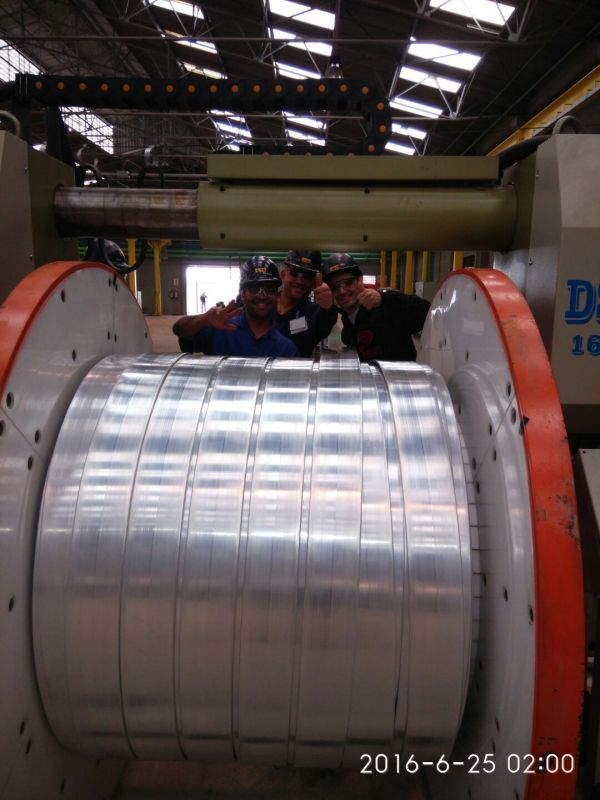

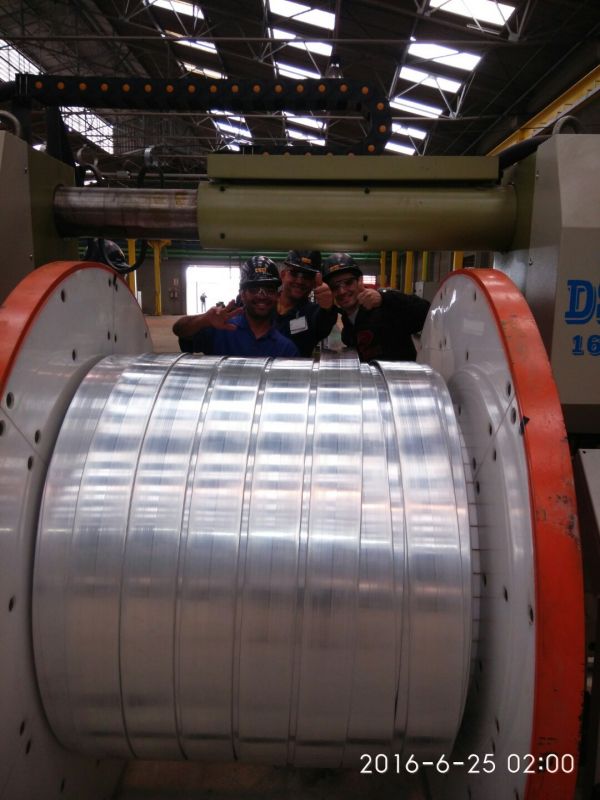

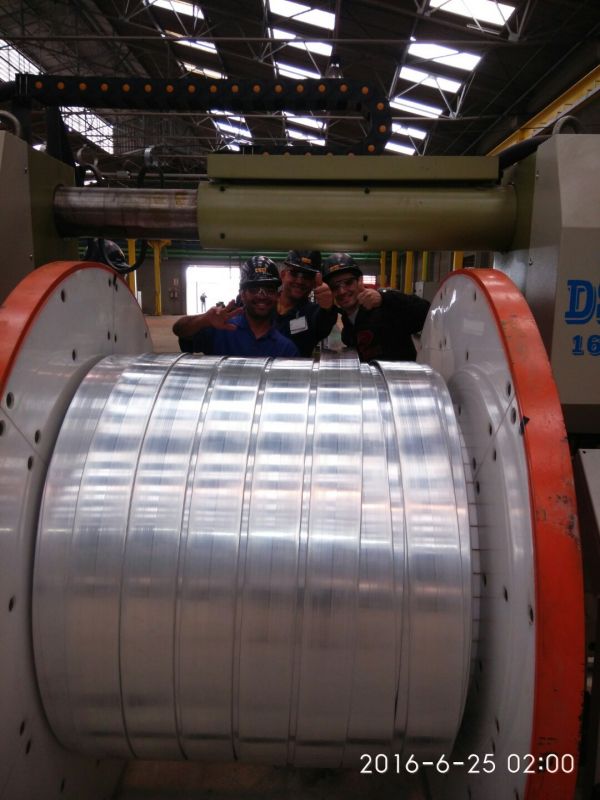

Packaging and transportation of continuous extrusion production line:

Continuous extrusion production line's packaging and transportation process strictly follows international standards to ensure that the products are not damaged during transportation and can reach customers smoothly. Aluminum sheet making machine will undergo strict quality inspections and undergo comprehensive cleaning and protection before leaving the factory. In order to prevent any possible scratches or bumps during transportation, the exterior of aluminum sheet making machine will be wrapped with shock-proof foam and anti-scratch protective film, and professional protective covers will be used to reinforce the vulnerable parts.

All aluminum sheet making machine parts will be classified and packed, and the main machine parts and auxiliary equipment will be packed separately, and reinforced with wooden boxes and steel frames to ensure the stability and safety of aluminum sheet making machine during transportation. The destination, handling requirements and safety warnings are clearly marked on each packaging box for quick identification during transportation and unloading.

During transportation, we cooperate with internationally renowned logistics companies to select the appropriate Aluminum plate forming machine transportation method, including sea, air and land transportation, to ensure that the products can reach the customer's factory or site in a timely and safe manner. For areas with special requirements, we provide Aluminum plate forming machine customized transportation solutions to cope with different transportation conditions.

Our technical support:

Customer service is the first point of contact for many customers often leaves last impression. It plays a vital role in building trust and maintaining relationship with customers.

Customer demand is our service content. We attach great importance to pre-sales service, strive to achieve personalized customization of continuous extrusion production line, and meet customers' needs for extruding new materials and producing new products using continuous extrusion production line. To this end, the Konform R&D Center is equipped with a complete set of test aluminum plate forming machine from 250 to 630, which can carry out process tests in advance according to customer requirements, so that customers can eliminate doubts and launch new projects with peace of mind.

We have a strong after-sales service team(about 30 mechanical and electrical engineers) with rich professional knowledge and practical experience of aluminum plate forming machine to provide commissioning, maintenance, and repair service to our customers all over the world. Continuous extrusion production line can reach to customer's plant at very short time, If they need, we can provide online support or remote control for 24 hours.

Service guarantee of Aluminum continuous extrusion machine:

To ensure that customers are more convenient during use, we provide each Aluminum Sheet Making Machine with a detailed user manual and operation video guide to help customers quickly familiarize themselves with the equipment operation process. The software platform supporting Aluminum plate forming machine supports switching between Chinese and English, which is convenient for global users to operate. If there are special needs, we can also provide program customization and debugging services based on the customer's production process to ensure that Continuous Extrusion Machine for Aluminum Busbar is better integrated into the customer's existing production line.

Continuous Extrusion Production Line has been fully debugged before leaving the factory, and standard interfaces are reserved, which can be seamlessly connected with the customer's feeding system, cooling system and back-end wire collection equipment. Aluminum sheet making machine's supporting documents also include maintenance plans, troubleshooting tables and FAQs to facilitate users' subsequent operation and maintenance. If you have any technical questions, our engineering team can also provide real-time assistance and guidance through the remote support system.