Introduction of aluminum continuous extrusion:

The conforming machine adopts advanced continuous extrusion technology, does not require preheating and preforming of billets, and can quickly and continuously form aluminum rods or aluminum alloy rods through friction drive and shear heating principles. Continuous extrusion machine for aluminum wire is an intelligent device designed specifically for the manufacture of aluminum wire and aluminum alloy materials. Therefore, aluminum conform machine can be widely used in power, communications, electronics, new energy, automobile and other industries.

Features of aluminum wire extruder:

1. Our aluminum continuous extrusion has high production capacity, low energy loss, and is easy to store.

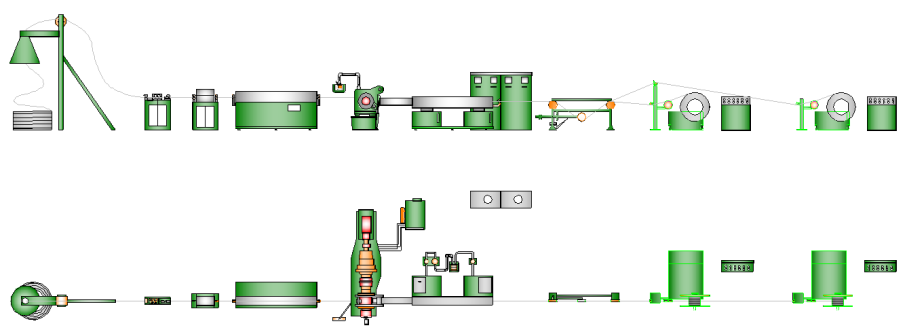

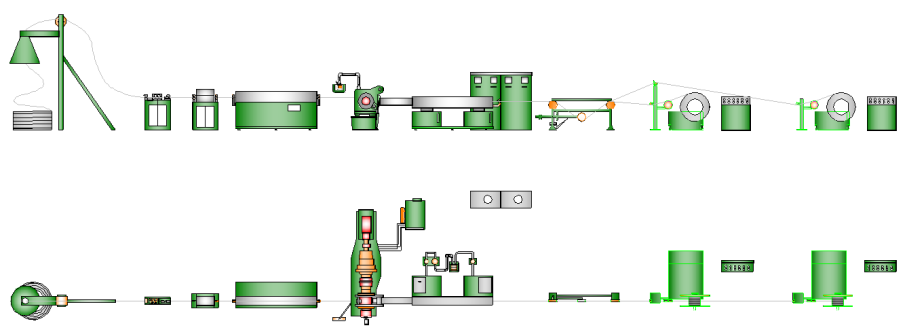

2. Our conforming machine system includes feeding mechanism, continuous extrusion main machine, cooling system, traction system, finished product coiling equipment, electrical control system and other components. Continuous extrusion machine for aluminum wire adopts mature structural design and optimized operating parameters.

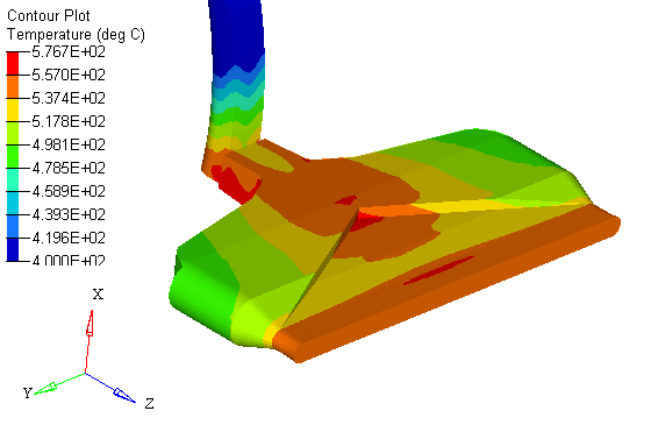

3. Aluminum conform machine adopts friction drive shear heating principle, does not require traditional heating furnace or resistance furnace, saves energy and improves efficiency.

Specifications of aluminum wire extruder:

| Model of aluminum wire extruder | LLJ300 | LLJ300H |

| Nominal diameter of extrusion wheel (mm) | 300 | 30

0 |

| product category of aluminum conform machine | Aluminum flat wire | Aluminum flat wire |

| Main motor power (kW) | 110 | 110 |

| Aluminum rod diameter (mm) | 9.5 | 9.5 |

| Maximum width of product (mm) | 30 | 30 |

| Product cross-sectional area (mm2) | 5~200 | 5~200 |

| Productivity (kg/h) of conforming machine | 160 | 280 |

Line layout of the continuous extrusion machine for aluminum round wire:

Uses of aluminum conform machine:

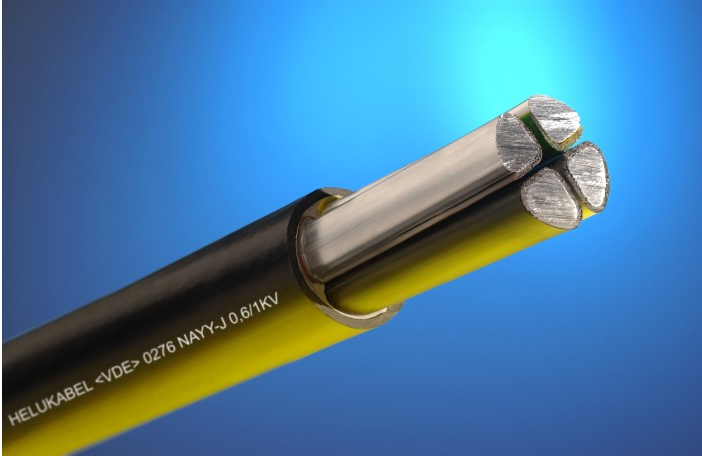

Aluminum wire extruder is mainly used for the precision manufacturing of aluminum and aluminum alloy wires. Aluminum continuous extrusion can be used to produce aluminum cable cores such as medium and high voltage conductors, overhead lines, and bare wires. Our conforming machine can provide aluminum wires with excellent conductivity for new energy vehicles and traditional vehicles. In the communications industry, our conforming machine can produce high-frequency, low-loss aluminum wires for communications to meet the needs of 5g infrastructure. The conforming machine we produce is also widely used in new energy equipment, building construction and other fields.

Instructions for use of aluminum conform machine:

When using the aluminum wire extruder, we must first cut the cleaned aluminum rods neatly according to the required length and place them on the feeding mechanism. Then turn on the power, start the main electronic control system of the aluminum continuous extrusion, enter the touch screen control interface, set the wire diameter, speed, temperature and other related parameters; the conforming machine softens the material by friction-driven heating. The softened aluminum material is continuously extruded through the die forming system, and the wire is cooled by the water cooling system and air cooling device of the continuous extrusion machine for aluminum wire. The traction mechanism of the aluminum conform machine steadily pulls the wire forward, and the formed aluminum wire is automatically reeled, arranged, measured and classified as needed.

About us:

Founded in 1993, Dalian Konform Technology Co., Ltd. is a leading global supplier of continuous extrusion technology and equipment. The company's research and development history in this field can be traced back to 1984. For more than 30 years, we have provided efficient continuous extrusion, continuous coating and continuous sheathing solutions to customers in the fields of non-ferrous metal processing and cable manufacturing.