Aluminum sector conductor extrusion line

Main uses of:

Producing fan-shaped aluminum wires for cables: Aluminum sector conductor extrusion line is widely used as a conductive material in high-voltage or medium-voltage cables.

Processing aluminum conductors of various specifications: Sector Conductor Continuous Extrusion Line can produce fan-shaped aluminum conductors of different sizes as needed.

Meeting the needs of the power industry: The products produced by Aluminum Sector Conductor Continuous Extrusion Line are suitable for power engineering, substations, transmission lines and other scenarios.

Product introduction of Aluminum sector conductor extrusion line:

Aluminum sector conductor extrusion line is a device used to process aluminum rods into fan-shaped aluminum conductors, mainly used in the production of power cables. Sector Conductor Continuous Extrusion Line runs smoothly, is easy to operate, can work continuously, and improves production efficiency. The aluminum conductors made by Sector Conductor Continuous Extrusion Line have uniform shapes and accurate sizes, which are very suitable for factories that need to mass-produce cable conductors. It is a commonly used and practical equipment in the power industry.

Specifications of Aluminum Sector Conductor Continuous Extrusion Line:

| Model | LLJ350 | LLJ400 |

| Nominal diameter of extrusion wheel (mm) | 350 | 400 |

| product category | Sector/shaped conductor | Aluminium platoon |

| Main motor power (kW) | 160 | 250 |

| Aluminum rod diameter (mm) | 2×9.5/15 | 2×15/15 |

| Maximum width of product (mm) | —— | 170 |

| Product cross-sectional area (mm2) | 25~300 | 75~2000 |

| Productivity (kg/h) | 260 | 600/900 |

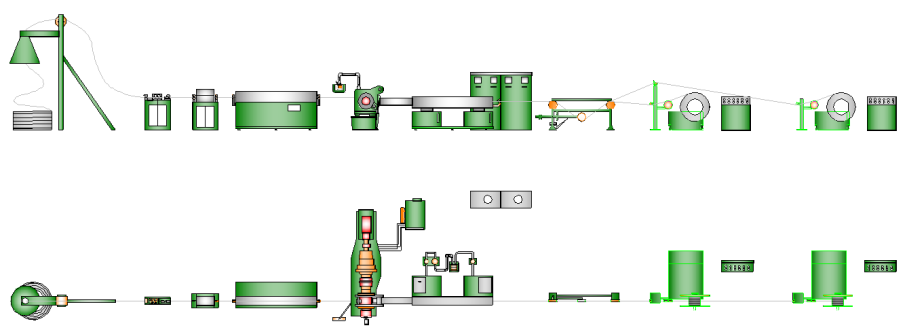

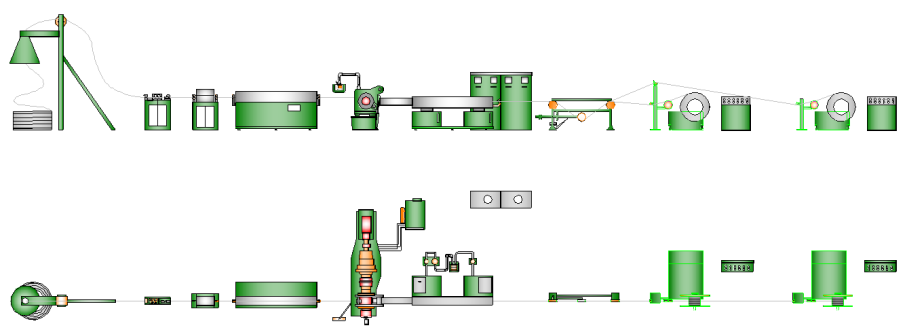

Line layout of the Aluminum Sector Conductor Continuous Extrusion Line:

What to do if machine suddenly stops:

Immediately cut off the power supply: to ensure personnel safety and prevent equipment damage or misoperation.

Check the cause of the fault: check whether it is a power failure, overload protection activation, raw material jamming or loose parts.

Clean the inside of the equipment: remove the residual aluminum material in the extrusion cavity to avoid clogging or damage to the mold.

Notify the technician: If you cannot judge or eliminate it yourself, you should contact the maintenance or technician in time.

Check before restarting: After troubleshooting, check whether each system is normal and restart after confirming safety.

How to clean the machine?

When cleaning the aluminum fan-shaped conductor extrusion production line, you need to turn off the power first to ensure that the equipment is completely shut down and cooled to avoid burns or misoperation. Special tools should be used during the cleaning process to avoid scratching the mold or extrusion cavity surface with hard objects. Be careful when removing residual aluminum to prevent damage to internal parts. After cleaning, you also need to check whether all components are firmly installed and whether the lubrication system is normal to ensure that the equipment runs smoothly and safely when it is started next time.

Our advantage:

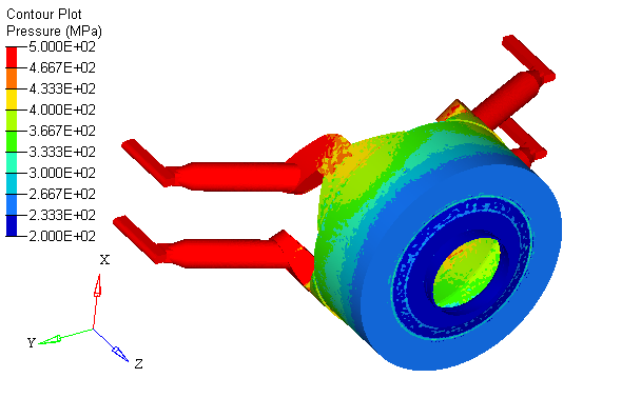

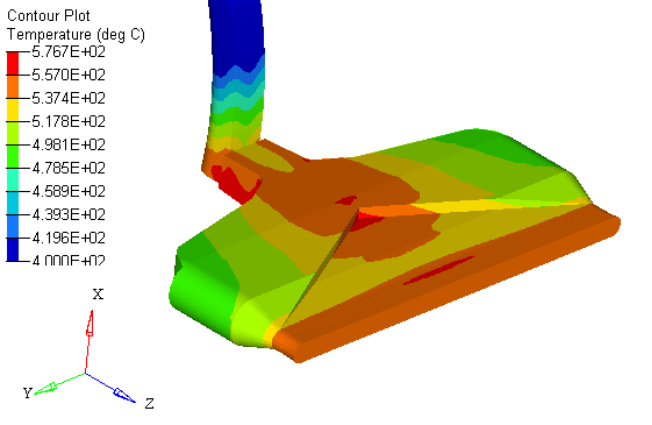

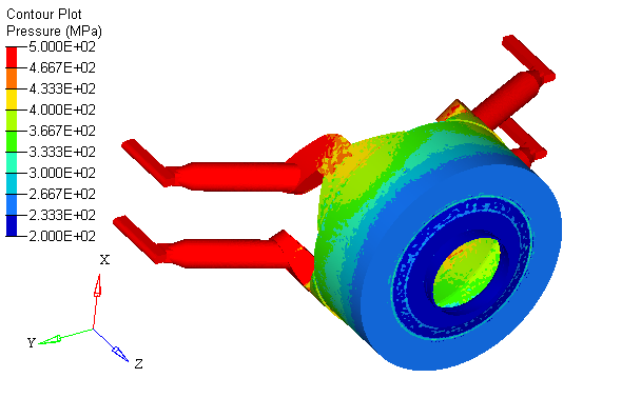

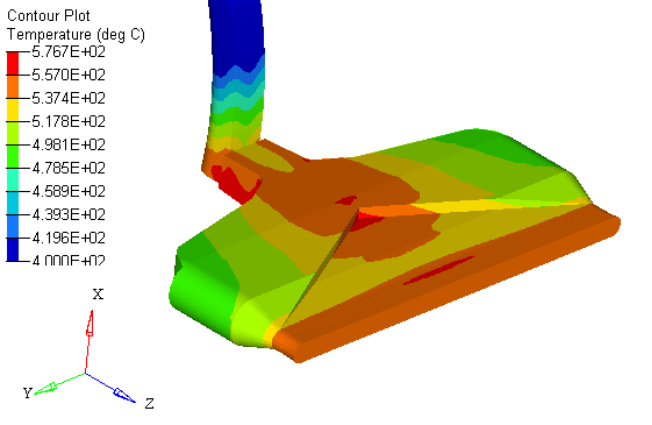

We use advanced simulation software to analyze the speed, pressure, and temperature of the metal during the continuous extrusion process. This helps us accurately determine the required load for the machine and tooling, making sure the design is reliable. With 3D design software, we create the structure of the machine and perform strength calculations on key parts to ensure the equipment is strong, stable, and well-designed.

About us:

Dalian Konform is a manufacturing enterprise integrating R&D, production and service, focusing on the continuous optimization of metal processing equipment. The company has a number of national patents and is at the forefront of the industry in terms of copper and aluminum alloy continuous extrusion technology. Whether it is standardized equipment or personalized customization, we can provide customers with professional and efficient solutions.