Menu

- Home

- Products

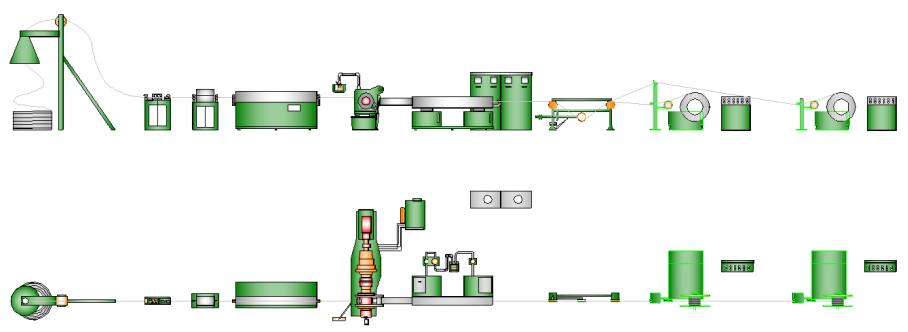

- Continuous Extrusion Machine for Copper

- Continuous Extrusion Machine for Aluminum

- Continuous Cladding Machine for Aluminum

- Continuous Casting And Continuous Extrusion Production Line for Aluminum Alloy

- Continuous Casting Machine for Copper Rod

- Hydraulic Drawing Machine for Copper Bar

- News

- product News

- company news

- Video

- Case

- Factory Show

- Factory Display

- Warehouse

- Contact Us

- About Us

- Company Style

- Certificate

- Exhibition

- Service

- Delivery

- Responsibility

Search