Product introduction of Conform Machine of Aluminum Sector Condutor:

Conform Machine of Aluminum Sector Condutor is a machine that processes aluminum rods into fan-shaped aluminum wires, mainly used to produce conductors in power cables. The operation of Copper Aluminum Conductor Extruder is very simple. After putting the aluminum rods in, after continuous extrusion, the fan-shaped aluminum wires with uniform shape and smooth surface can be quickly made. The Copper Aluminum Conductor Extruder we produce has been improved, with high production efficiency, saving time and labor, and is very suitable for mass production in cable factories.

Main purposes of Extruder for Aluminum Wire:

Round aluminum wire: used for wires and cables, conductive materials, etc.

Fan-shaped aluminum conductor: commonly used in the conductor part of high-voltage cables

Flat aluminum wire: used in electronic parts, connectors, etc.

Special-shaped aluminum wire: customized according to customer needs, aluminum products for special purposes

Aluminum core wire harness material: widely used in internal connecting wires of automobiles and home appliances

These products are widely used in multiple industries such as electricity, electrical, electronics, and transportation, and are important outputs of various aluminum processing companies.

Specifications of Extruder for Aluminum Wire:

| Model | LLJ350 | LLJ400 |

| Nominal diameter of extrusion wheel (mm) | 350 | 400 |

| product category | Sector/shaped conductor | Aluminium platoon |

| Main motor power (kW) | 160 | 250 |

| Aluminum rod diameter (mm) | 2×9.5/15 | 2×15/15 |

| Maximum width of product (mm) | —— | 170 |

| Product cross-sectional area (mm2) | 25~300 | 75~2000 |

| Productivity (kg/h) | 260 | 600/900 |

Replace Copper Aluminum Conductor Extruder parts in time:

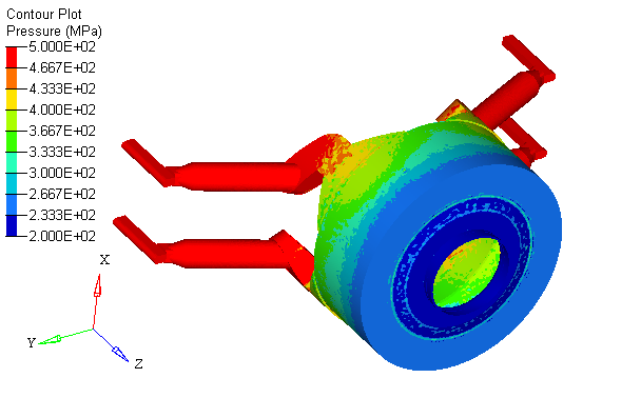

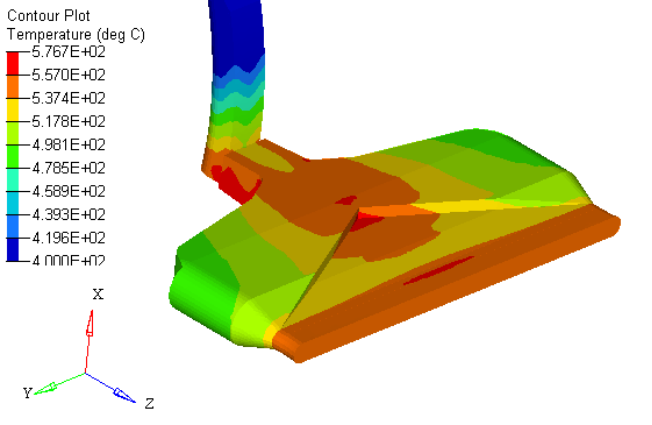

After long-term operation, some parts of Copper Aluminum Conductor Extruder Solid Conductor Machine will wear out naturally and need to be replaced regularly to ensure stable operation of the equipment. Common parts that need to be replaced include molds, extrusion wheels, bearings, seals, etc. The replacement process of these parts is simple to operate and easy to install. Generally, they can be completed according to the instruction manual or under the guidance of professional technicians. Konform also provides original parts and technical support to ensure that customers can quickly resume production and reduce downtime. Regular replacement of wearing parts can not only improve product quality, but also extend the service life of Extruder for Aluminum Wire Solid Conductor Machine.

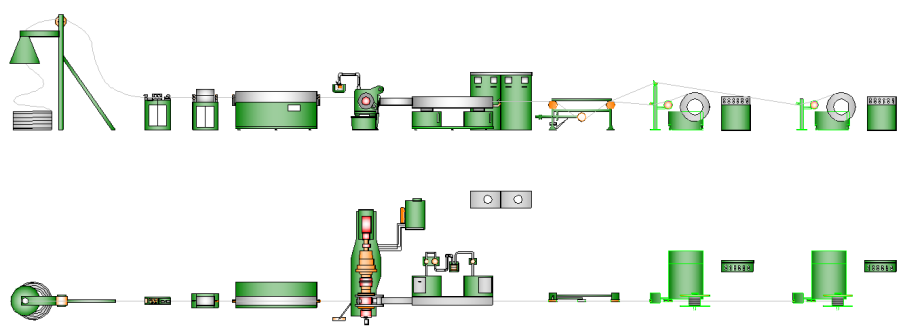

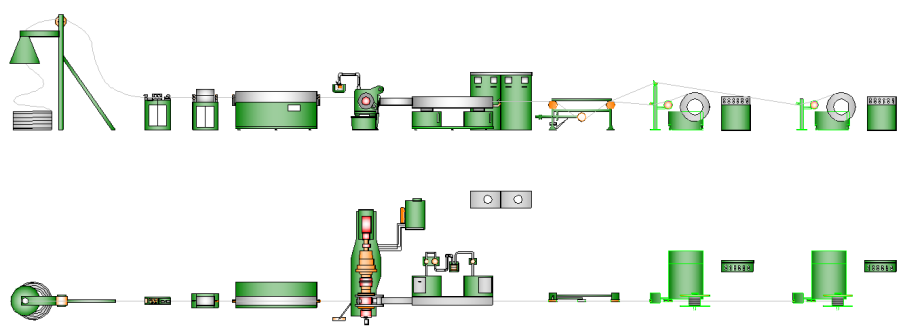

Line layout of the Extruder for Aluminum Wire:

About us:

Dalian Konform focuses on technology and specializes in the design and manufacture of metal extrusion equipment. Our Extruder for Aluminum Wires are widely used in the fields of wire and cable, rail transportation, electronic power, etc. Over the years, we have continuously innovated and upgraded, and provided customized solutions based on customer needs to help users improve production capacity and efficiency. Our products are exported overseas and have gained a good reputation.