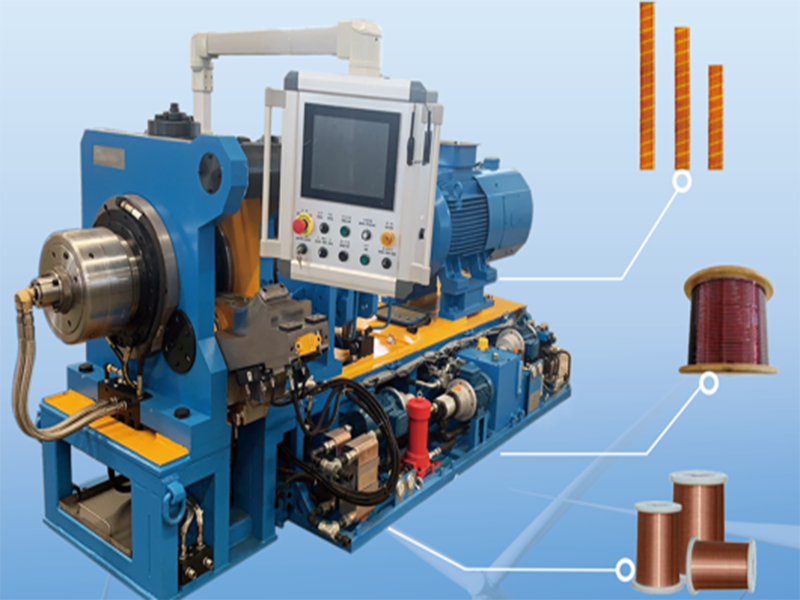

Main uses of Conform machine for copper wire:

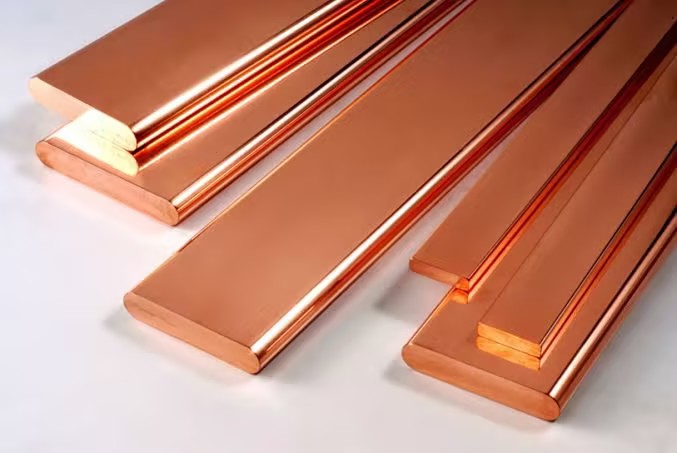

Conform machine for copper wire can produce copper flat wire, small copper busbar, commutator ladder, round wire and other copper conductors.

Features of Conform Machine:

1. Conform Machine uses advanced technology to make the product meet the production needs of customers.

2. Conform Machine uses high-quality materials and is strong and durable.

3. Conform machine for copper wire has higher safety and reduces risks.

Specifications of Conform machine(Conform machine for copper wire) for Magnet Wire:

| Model | TLJ300 | TLJ300H | TLJ350 |

| Nominal diameter of extrusion wheel(mm) | 300 | 300 | 350 |

| Main motor power(kw) | 90 | 110 | 160 |

| Copper rod diameter(mm) | 12.5 | 12.5 | 12.5 |

| Maximum width of flat wire products(mm) | 40 | 30 | 100 |

| Minimum diameter of round product(mm) | 2.6 | 2.6 | 4.5~50 |

| Cross-sectional area of flat wire products(mm2) | 5~200 | 5~150 | 15~1000 |

| Efficiency(kg/h) | 480 | 800 | 780 |

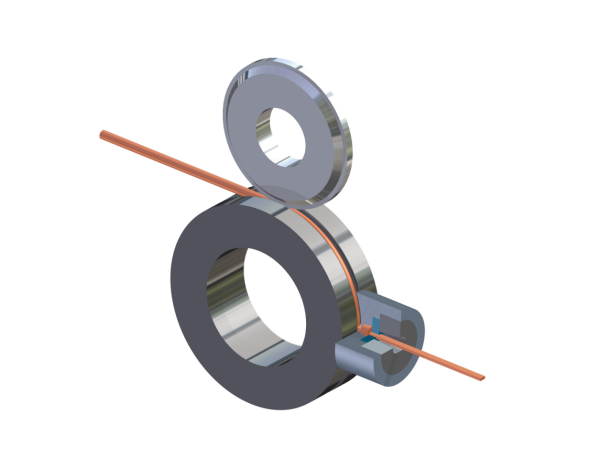

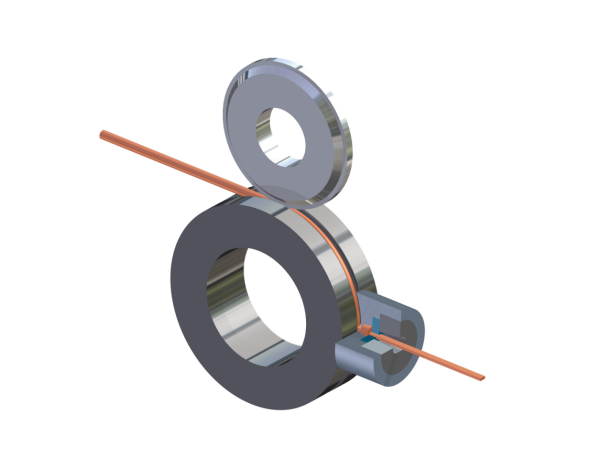

Schematic diagram of continuous extrusion principle:

The Principle of Continuous Extrusion(Konform machine):

The metal bar of the Conform machine for copper wire is dragged into the continuously rotating extrusion wheel under the friction force of the wheel groove. When it reaches the abutment point, the bar is forced to change direction and enter the cavity from the radial direction. Under the high temperature and high pressure generated by the friction deformation, the plastic deformation condition is reached, and the material is extruded from the die to form a solid or hollow profile product.

Mainly uses of Conform machine:

Conform machine for copper wire mainly produces copper flat wire, small copper busbar, commutator trapezoidal round wire and other copper conductors.

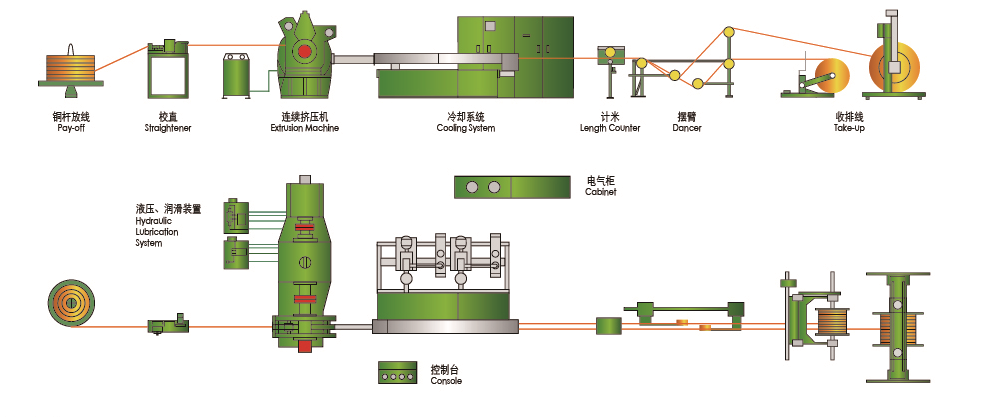

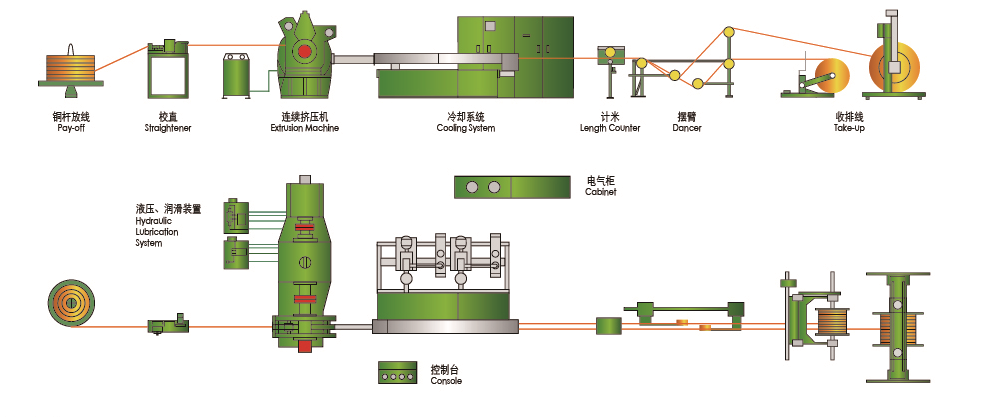

Conform machine(Production line) layout

Company Profile:

Originally established in 1993, Dalian Konform Technology Co., Ltd. is a world-leading provider of the continuous extrusion technology and equipment(continuous extrsuion machine), we specializes in continuous extrusion technology research and equipment manufacturing. Our research in this area can date back to 1984. Since then, Dalian Konform have grown into a world-class R&D team and developed seven series of copper and aluminum continuous extrusion and cladding/sheathing equipment with more than thirty models. 75 national and international patents have been granted in recognizing our innovation. With over 2100 production lines operating in 53 countries and regions in six continents, We are proudly the world 's largest supplier of continuous extrusion technology and equipment, promoting technological progress for non-ferrous metal processing and wire and cable manufacturing industries all over the world.

Machine Development Milestone of Dalian Konform

Year of 2004 | Dalian Konform developed LLJ300A continuous extrusion machine for Microchannel aluminum tube first in China |

Year of 2005 | Dalian Konform developed TLJ400 continuous extrusion machine for copper/aluminum busbar first in China |

Year of 2008 | Dalian Konform developed TLJ630 continuous extrusion machine for copper strip first in China |

Year of 2009 | Dalian Konform developed TLJ500 continuous extrusion machine for copper busbar first in China |

Year of 2010 | Dalian Konform developed LLJ300B continuous extrusion machine for aluminum tube first in China |

Year of 2015 | Dalian Konform developed continuous casting and extrusion machine for aluminum first in China |

Year of 2016 | Dalian Konform developed SSLB500 continuous sheathing machine for high voltage cable sheath in the world |

Year of 2018 | Dalian Konform developed U type continuous extrusion machine for copper strip first in China |

Year of 2019 | Dalian Konform developed 300H high speed continuous extrusion machine for copper&aluminum in the world |

Year of 2022 | Dalian Konform developed TLJ800U continuous extrusion machine for copper strip first in the world |

Dalian Konform Service

We pay great attention to customer needs. Equipped with our entire production line ranging from model 250-800, our lab can carry out production test for new products and new material required by our customers. Through effective presale collaboration, we provide valuable technical advice and recommendations to and develop close working relationships with customers, so that they can confidently place an order.

We have a strong after-sales service team with rich professional knowledge and practical experience to provide commissioning, maintenance, and repair service to our customers all over the world. We also support our customers with technical consultation around the clock through email or online meeting.