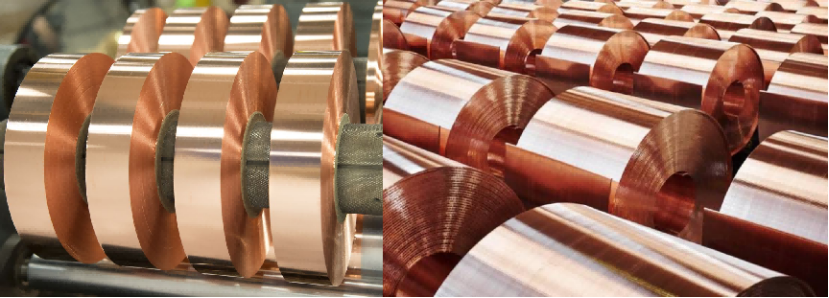

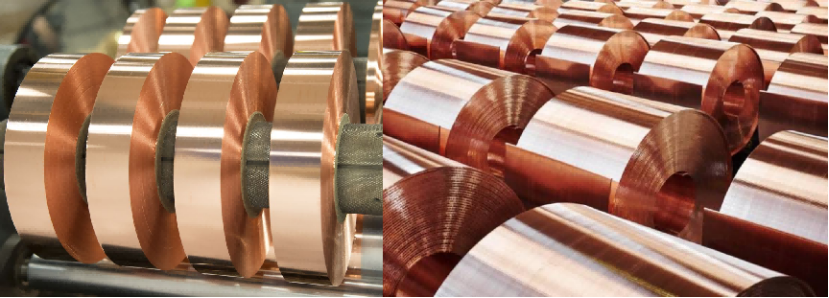

Product Introduction of Copper Brass Machine:

Copper Brass Machine is a kind of equipment specially used to process copper or brass materials into wires and bars of various shapes. It is easy to operate and has high production efficiency. Copper Alloy Extrusion Line can run stably after our design and production, and is suitable for long-term continuous use. It is widely used in electrical, hardware, electronic and other industries. Our factory has a number of independent patented technologies in Copper Alloy Extrusion Line structural design and energy-saving control, which makes the product more energy-saving and durable during use. At the same time, the finished product has a smooth surface and uniform size.

Product advantages of Copper Alloy Continuous Production Line:

Copper Alloy Continuous Production Line's operating procedures are simple and clear, and the mold can be used directly without complicated mold matching and debugging. It is also very convenient to replace, which greatly saves production preparation time. Copper Alloy Continuous Production Line is mainly used to manufacture copper rods, copper bars and special-shaped copper profiles of various specifications, suitable for multiple industries such as electricity, electronics, and hardware. Copper Alloy Extrusion Line has the advantages of compact structure, stable operation, and simple maintenance, which can meet customers' needs for high efficiency and diversified products.

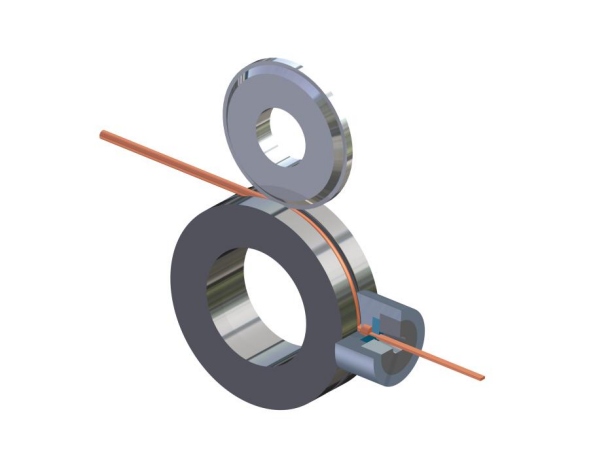

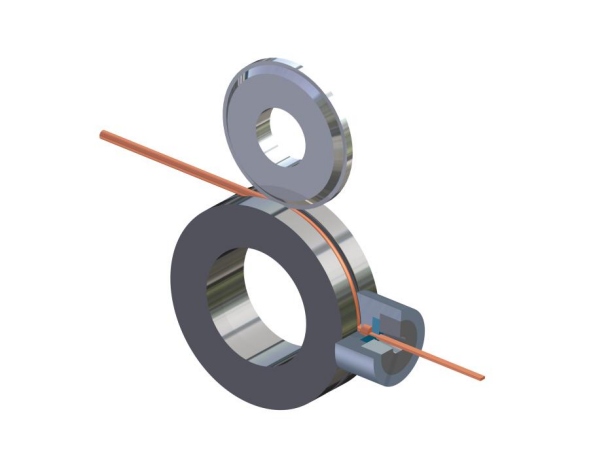

Schematic diagram of Copper Alloy Extrusion Line principle:

Specifications of Continuous Extrusion Production Line for Copper Alloy:

| Model | TLJ400 | TLJ500 |

| Nominal diameter of extrusion wheel (mm) | 400 | 500 |

| Main motor power (kW) | 250 | 355 |

| Diameter of copper rod (mm) | 20 | 25 |

| Maximum width of product (mm) | 170 | 260 |

| Diameter of round rod product (mm)/Maximum aspect ratio (b/a) | 8~90 | 12~100 |

| Product cross-sectional area (mm2)/Copper strip thickness (mm) | 75~2000 | 300~3200 |

| Productivity (kg/h) | 1200 | 1800 |

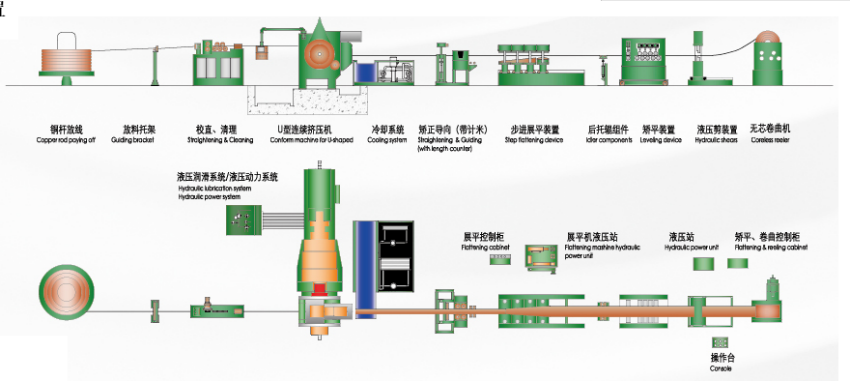

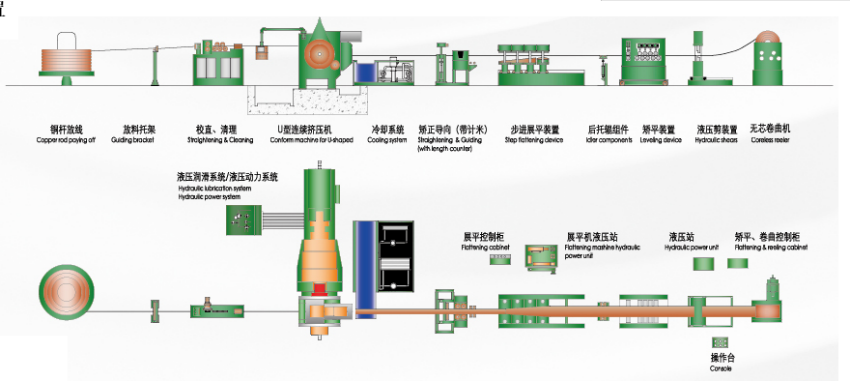

Production line layout of Continuous Extrusion Production Line for Copper Alloy:

Our technical support:

Dalian Konform Technology Co., Ltd. is the first in my country to successfully develop 250, 300, 350, 400, 500, 550 and 630 three series and 24 specifications of copper and aluminum continuous extrusion and Continuous Extrusion Production Line for Copper Alloy sets with more than 30 patented technologies equipment. Passed ISO9001 quality system certification and EU safety CE certification, it has supplied more than 1,500 production lines for domestic and foreign users, and its products are sold in 29 domestic provinces, municipalities and autonomous regions, and exported to 53 in Asia, Europe, America, Australia and Africa. country and region.

About us:

Dalian Konform's extrusion technology is widely used in producing a variety of high-performance products such as AS wire, OPGW, copper flat wire, aluminum tubes, copper bus bars, Copper Brass Machine, and aluminum sheathing for power cables.