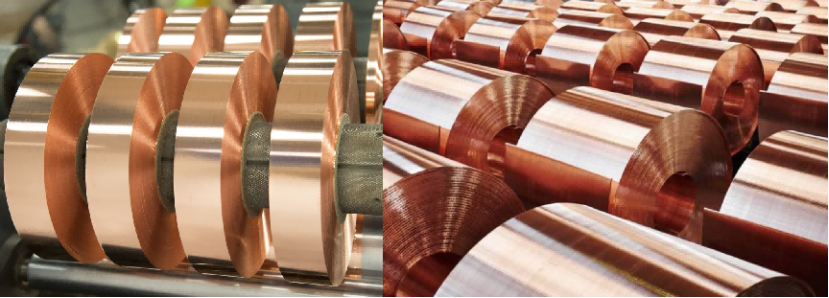

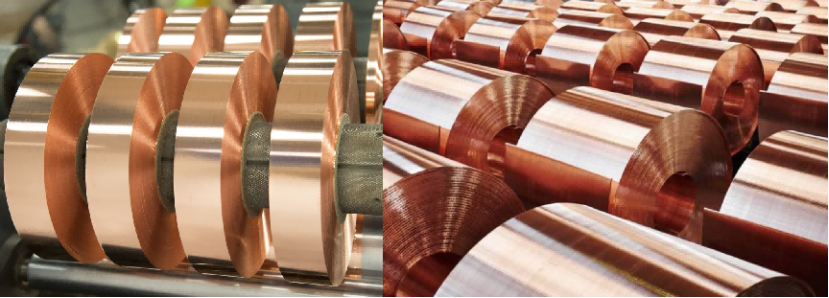

Product introduction of metal extrusion machine:

Metal extrusion machine produced by konform is a kind of equipment specially used for processing copper alloy materials. It can process copper alloy bars into wires or bars of various shapes. Extruding copper wire metal extrusion machine runs smoothly, has fast speed and is easy to operate. It is especially suitable for factories that need large-scale and high-efficiency production. Our factory has a number of national patents related to extrusion technology. It has unique designs in equipment structure and energy saving, which can help customers improve production efficiency and save costs. Each extruding copper wire metal extrusion machine is strictly tested before leaving the factory to ensure reliable quality and safe use.

Purpose of copper extrusion machine:

The production process of copper extrusion machine is simple and efficient. The mold can be directly formed without the tedious mold matching process. The replacement is also very convenient, saving a lot of time and labor costs. The extruding copper wire produced by konform is mainly used to produce copper bars, copper rods and special-shaped copper profiles of various specifications, which are widely used in power equipment, hardware manufacturing, electronic components and other industries. Through the continuous extrusion process, the product surface is smooth, the size is stable, and the production efficiency is higher. Our extruding copper wire incorporates self-developed patented technology and has obvious advantages in energy saving and durability.

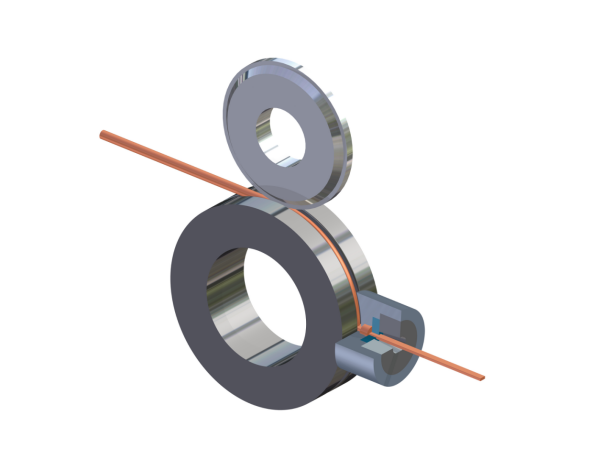

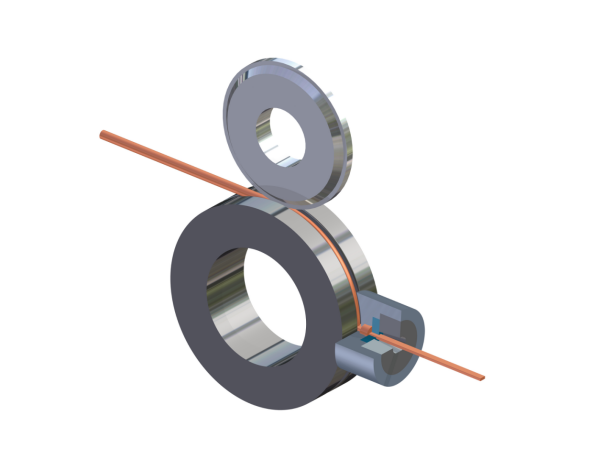

Schematic diagram of continuous extrusion principle:

Specifications of extruding copper wire:

| Model | TLJ300 | TLJ400 | TLJ500 |

| Nominal diameter of extrusion wheel(mm) | 300 | 400 | 500 |

| Main motor power(kw) | 90 | 250 | 355 |

| Copper rod diameter(mm) | 12.5 | 20 | 25 |

| Maximum width of flat wire products(mm) | 40 | 170 | 260 |

| Minimum diameter of round product(mm) | 2.6 | 8~90 | 12~100 |

| Cross-sectional area of flat wire products(mm2) | 5~200 | 75~2000 | 300~3200 |

| Efficiency(kg/h) | 480 | 1200 | 1800 |

Product quality inspection of extruding copper wire metal extrusion machine:

Our copper extrusion machine quality inspection department is an important part of ensuring product quality. It is equipped with advanced testing equipment and an experienced quality inspection team. From the entry of raw materials to the delivery of the whole machine, each process is strictly controlled to ensure the accuracy, performance and stability of each copper extrusion machine. We implement full-process quality control, conduct multiple tests on key components such as size, strength, and assembly, and conduct actual machine operation tests during the copper extrusion machine commissioning phase to simulate the customer's use environment to ensure that the equipment can run efficiently upon delivery.

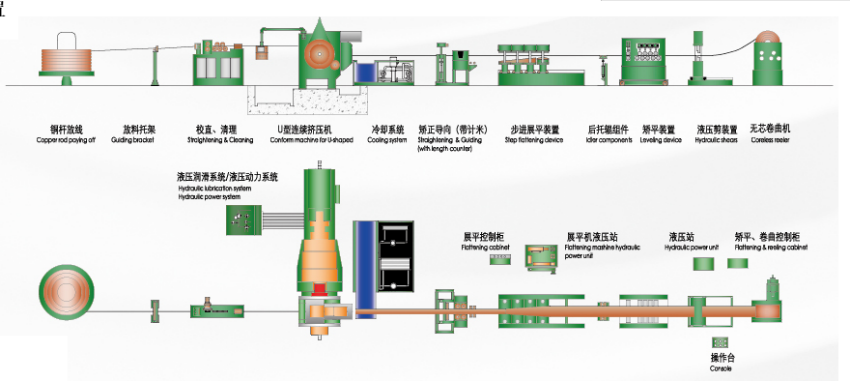

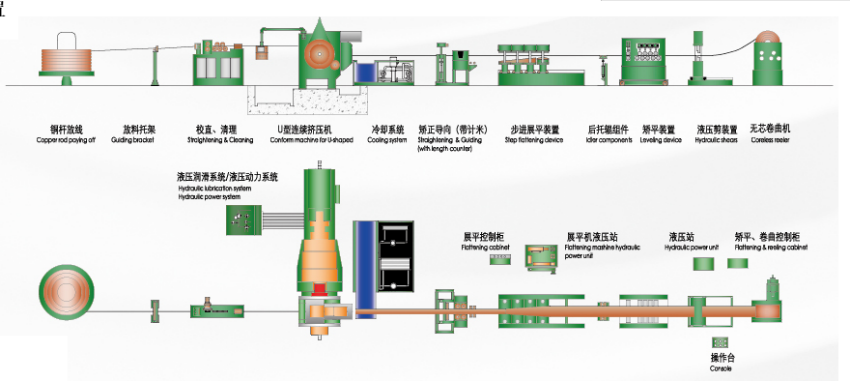

Production line layout of Extrusion Machine for Copper Alloy

Our technical support:

Over the years, we have served customers from 52 countries across all six continents, delivering more than 1,500 production lines by 2020, with continuous growth ever since.

\