Technical introduction of Copper Bar Continuous Extrusion Machine/Continuous Extruder:

Driven by the friction between the annular groove of the extrusion wheel and the material, the normal temperature material is continuously fed into the arc-shaped extrusion cylinder formed by the extrusion wheel and the cavity by the rotating extrusion wheel. Under the action, the metal temperature rises and dynamic recrystallization occurs; after receiving the block of the block, the flow direction is changed into the mold cavity, and the continuous feeding of the material increases the pressure in the mold cavity.

Introduction of Conform Machine for Copper Bar:

Conform Machine for Copper Bar is a kind of equipment used for copper material processing. Copper bar conform machine adopts advanced technology. Conform Machine for Copper Bar can continuously extrude copper bars into copper products of various shapes. Therefore, Continuous Extruder is widely used in the manufacturing process of cables, conductors, heat sinks and other precision copper products. This continuous extruder adopts advanced continuous extrusion technology. Therefore, the conform machine for copper bar can not only improve production efficiency, but also ensure product quality.

Application of Copper Bar Conform Machine:

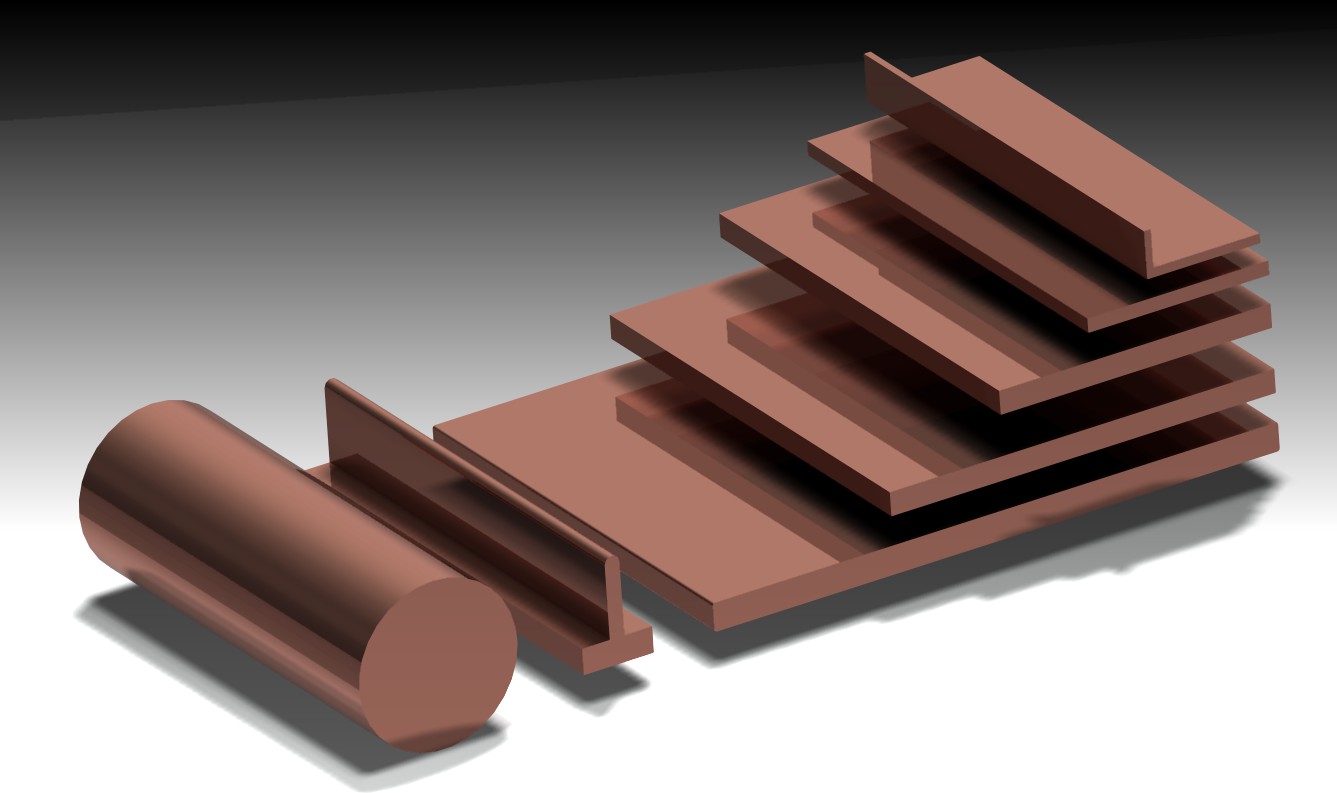

Copper bar continuous extrusion machine can be used to produce high-quality copper bars, copper strips and other conductive materials, which are widely used in power transformers, electric control cabinets, high-voltage transmission equipment and other fields. Conform machine for copper bar can produce copper strips and copper wires of different specifications. Compared with traditional processing methods, continuous extruder can reduce waste and improve material utilization. Continuous extruder can also produce high-conductivity copper bars, electric vehicle battery connectors and other products for the electrical system of new energy vehicles. Continuous extruder can also produce high-strength and high-durability copper water pipes. And Continuous extruder can produce high-precision and high-purity copper products. So Continuous extruder can be applied to many industries.

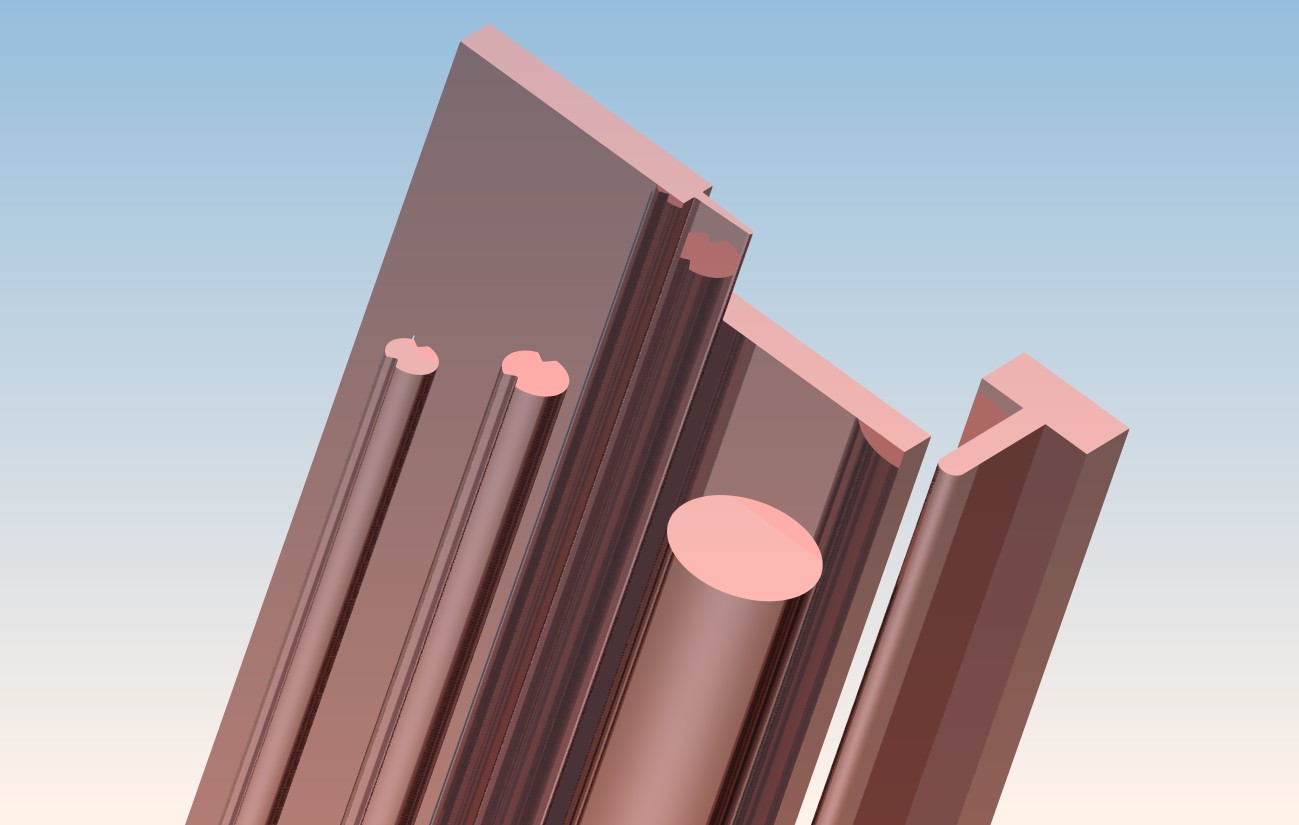

Purpose of Continuous Extrusion Machine/Continuous Extruder for Copper busbar&bar&profile:

Copper Bar Continuous Extrusion Machine can produce various specifications of copper bar, copper busbar and copper profile

Specifications of Copper Bar Continuous Extrusion Machine/Continuous Extruder:

Model | TLJ400 | TLJ500 | TLJ630 |

Nominal diameter of extrusion wheel (mm) | 400 | 500 | 630 |

Main motor power (kw) | 250 | 355 | 600 |

Copper rod diameter (mm) | 20 | 25 | 30 |

Product maximum width (mm) | 170 | 260 | 320 |

Round bar product diameter (mm) | 8~90 | 12~100 | 12~100 |

Product cross-sectional area (mm²) | 75~2000 | 300~3200 | 600~6400 |

Productivity (kg/h) | 1200 | 1800 | 2800 |

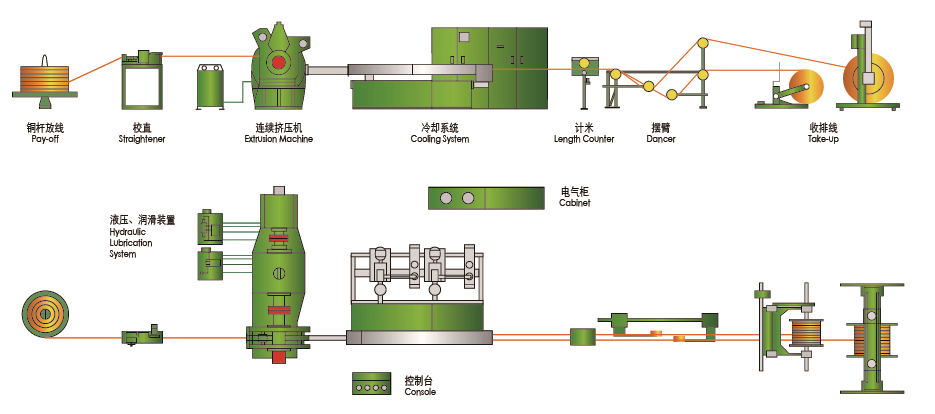

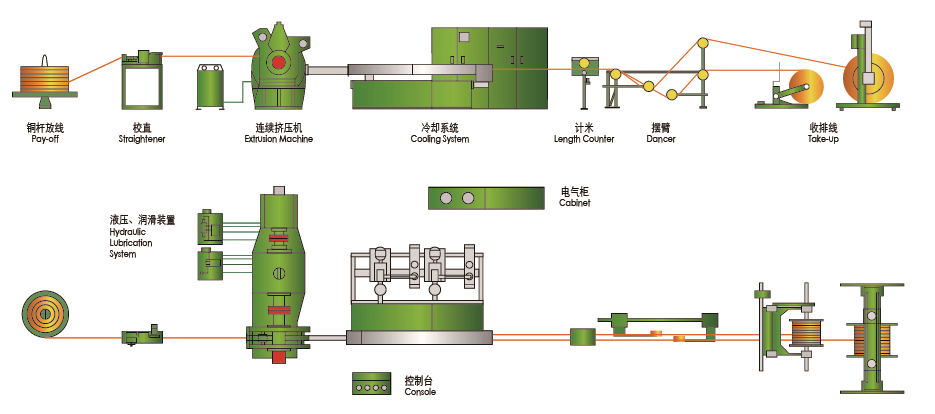

Continuous Extrusion Machine for Copper Bar production line layout:

Our advantages: Advanced manufacturing, scientific management.

Our copper bar continuous extrusion machine adopts advanced processing methods and strict processing technology to ensure the excellent quality and long-lasting life of Konform copper bar conform machine and other products. Copper bar conform machine and other products are fully debugged before leaving the factory, and will never bring any defects to customers.

We have established a strict supply chain management system: The raw materials and supporting components of copper bar conform machine and other products are provided by well-known domestic and foreign companies, and all electrical components are first-class domestic and foreign brands.

Konform Manufacturing:

We take great care in manufacturing products like Copper Bar Conform Machine. We have the latest manufacturing machinery from world-renowned brands. We source raw materials and components for products like Copper Bar Conform Machine from the best domestic and international sources, which must meet our stringent internal quality standards. We use a quality management system certified by ISO 9001:2008. The entire process of our Copper Bar Conform Machine is carried out in-house, and quality checks are carried out at every stage of production.

With the support of an ERP system that integrates sales, R&D, manufacturing, procurement and logistics, we are able to significantly shorten the manufacturing cycle of products like Conform Machine for Copper Bar. By moving from "engineer to order" to "configure to order", we can now respond to customers' diverse needs for Conform Machine for Copper Bar and deliver orders quickly.

Konform Service:

We pay great attention to customer needs. Equipped with our entire production line ranging from model 250-800, our lab can carry out production test for new products and new material required by our customers. Through effective presale collaboration, we provide valuable technical advice and recommendations to and develop close working relationships with customers, so that they can confidently place an order.

We have a strong after-sales service team with rich professional knowledge and practical experience to provide commissioning, maintenance, and repair service to our customers all over the world. We also support our customers with technical consultation around the clock through email or online meeting.