Product introduction of Brass Continuous Extrusion Machine:

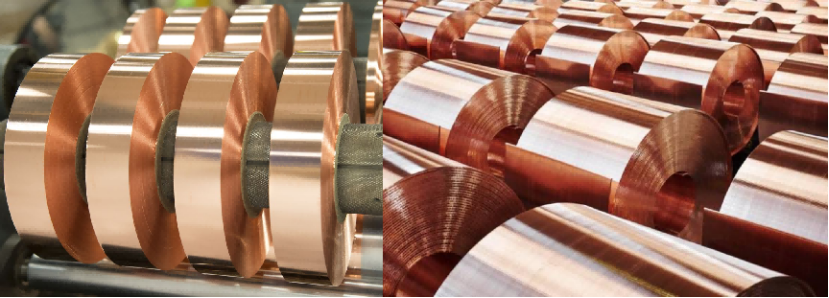

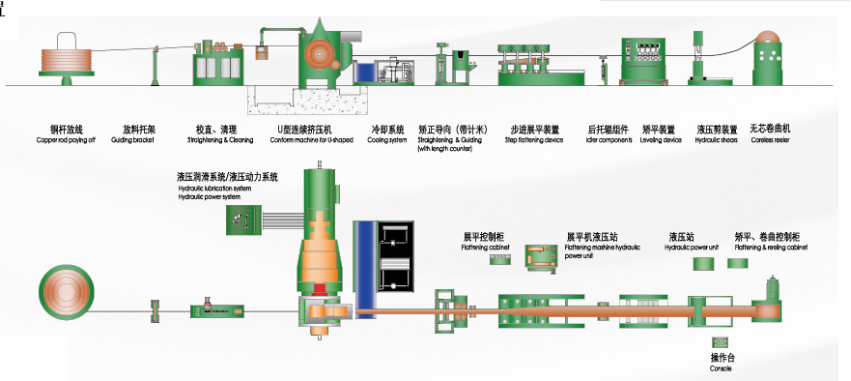

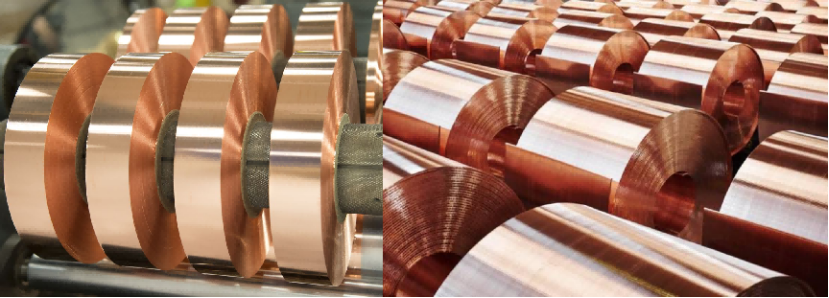

Brass Continuous Production Line is an efficient processing equipment, mainly used to process brass bars into brass products of various shapes, such as flat bars, copper strips, special-shaped wires, etc. Extrusion Machine for Lead Frame Strip Brass Extrusion Line uses continuous extrusion to allow brass to be directly deformed and formed without heating and melting. Brass Extrusion Line is widely used in electrical accessories, connectors, decorative hardware and other industries. Brass Continuous Extrusion Machine has a high degree of automation and is easy to operate. It is a good choice for modern brass processing companies to improve efficiency and reduce costs.

Purpose of Brass Continuous Extrusion Machine:

The production process of Brass Continuous Extrusion Machineis simple, the mold is directly formed without mold matching, and it is easy to replace. It is mainly used to produce various specifications of copper bars, copper bars, and profiles.

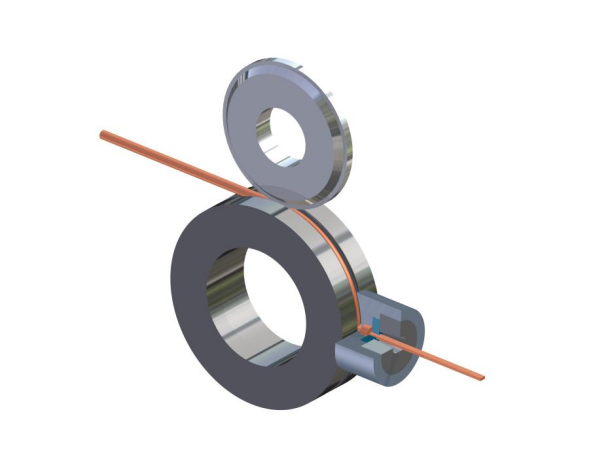

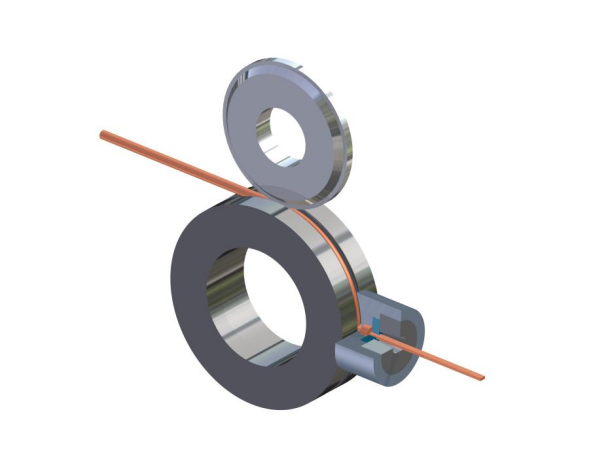

Schematic diagram of continuous extrusion principle:

Advantages of Brass Continuous Production Line:

1. Plastic deformation of feeding rod under the friction force and high temperature which eliminates the internal defects in the rodtself completely to ensure the final products with excellent product performance and high dimensional accuracy.

2. Neither preheating nor annealing, good quality products gained by extrusion process with lower power consumption.

3. With a single size rod feeding, Brass Extrusion Line could produce a wide size range of products by using different dies.

4. Brass Extrusion Line is easily and fast operated without any heavy w)rk or pollution during extrusion.

Specifications of Brass Continuous Production Line:

| Model | TLJ300 | TLJ400 |

| Nominal diameter of extrusion wheel(mm) | 300 | 400 |

| Main motor power(kw) | 90 | 250 |

| Copper rod diameter(mm) | 12.5 | 20 |

| Maximum width of flat wire products(mm) | 40 | 170 |

| Minimum diameter of round product(mm) | 2.6 | 8~90 |

| Cross-sectional area of flat wire products(mm2) | 5~200 | 75~2000 |

| Efficiency(kg/h) | 480 | 1200 |

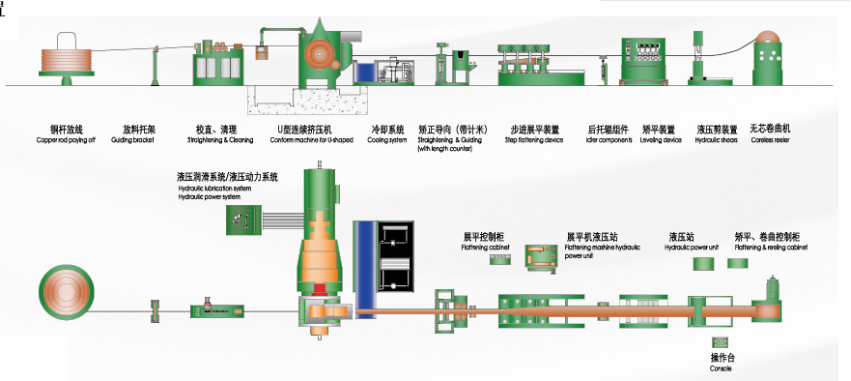

Production line layout of Brass Continuous Production Line:

Our technical support:

We prioritize customer needs as the core of our service. Emphasizing strong pre-sales support, we are committed to providing customized solutions tailored to each client's specific requirements for new material extrusion and innovative product development using continuous extrusion technology. To support this, the Konform R&D Center is fully equipped with a complete range of testing machines (from 250 to 630 models), allowing us to conduct process trials in advance based on customer requests. This helps clients verify feasibility, reduce uncertainty, and confidently move forward with new projects.