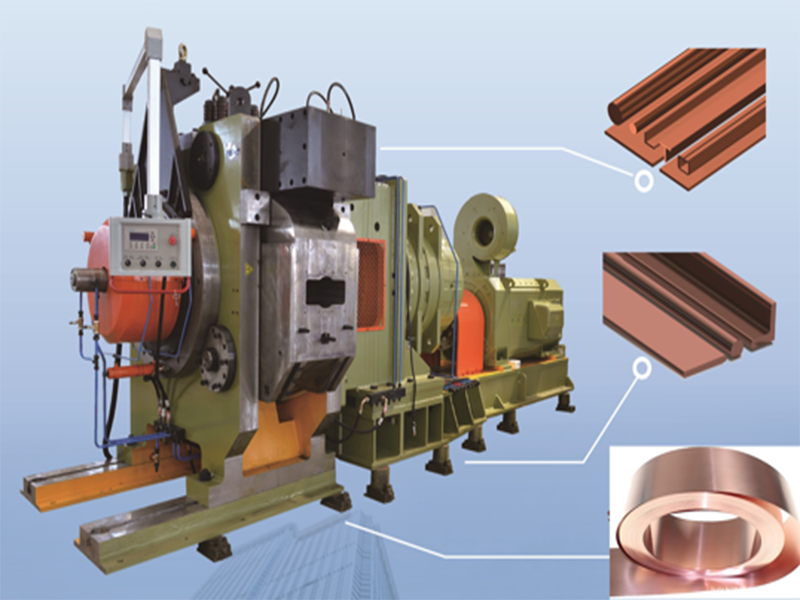

Purpose of Continuous extrusion machine for copper strip:

The production process of Continuous Extrusion Machine for Copper Strip is simple, the mold is directly formed without mold matching, and it is easy to replace. Copper Casting Machine is mainly used to produce various specifications of copper strip.

Brief Descriptions of Continuous extrusion machine for copper strip:

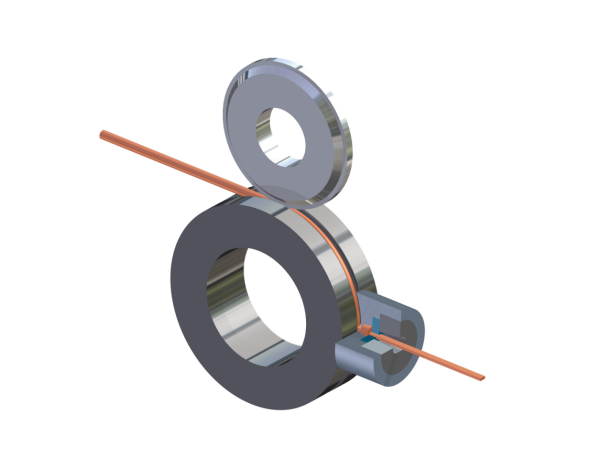

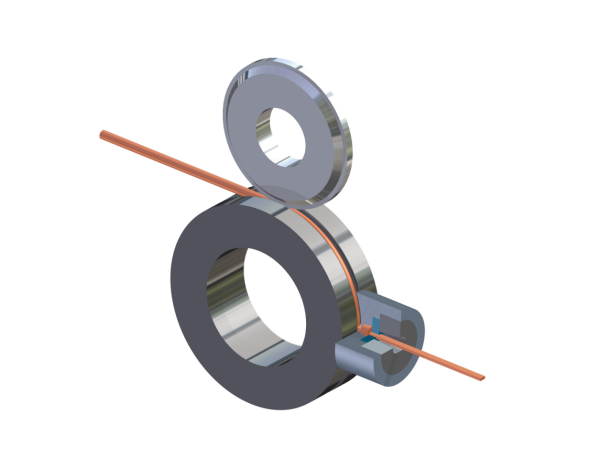

The revolving extrusion wheel of Copper strip extrusion machine is driven by a motor, and it guides the feedstock to enter the wheel groove. The feedstock is dragged into the chamber of Copper strip extrusion machine by the friction between the wheel groove and feedstock. The friction generates high temperature and heavy pressure, under the high temperate and pressure, the metal is formed into copper strip through a die. The Copper strip extrusion machine is soft and does not need anneal with smooth surface, high precision dimension.

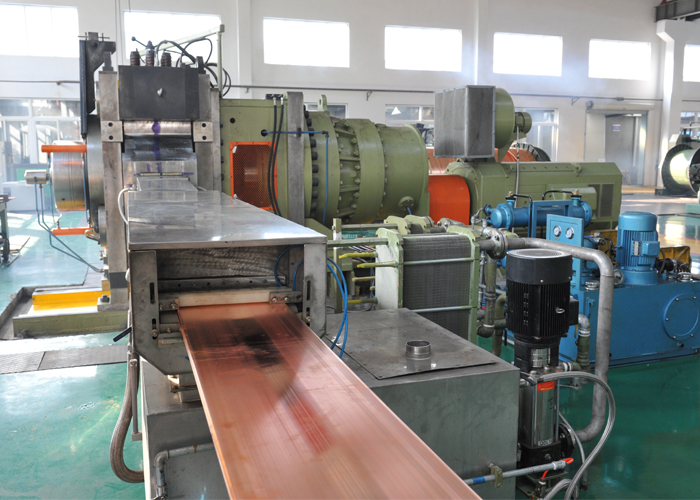

Centered around the Copper Casting Machine, the line is equipped with the straightener for copper rod, cooling systems, length counter, take-up stand and other auxiliary equipments based on the actual requirement.

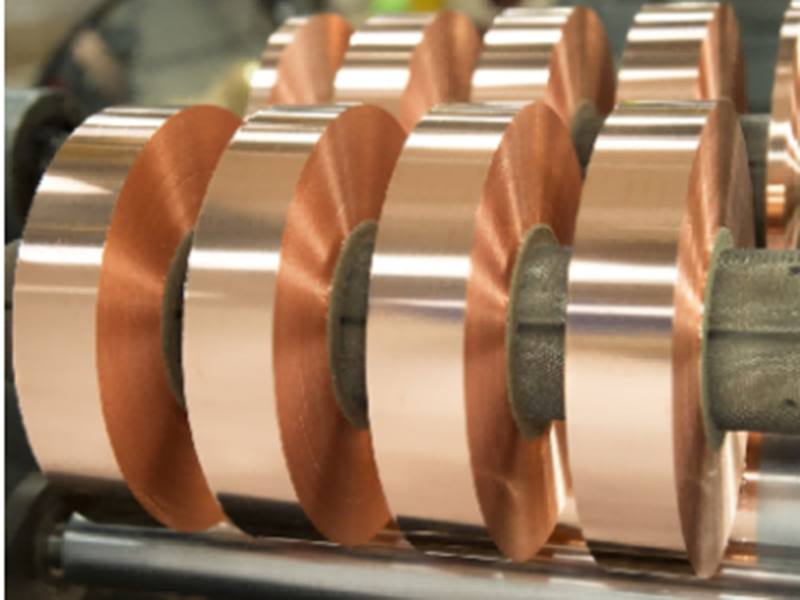

Copper Casting Machine Production flow: Copper Feedstock Pay-off →Straightener→ Continuous Extrusion → Product Cooling → Blow Dry → Length Counter → Take-up.

Schematic diagram of continuous extrusion principle:

Specifications of Copper Strip Continuous Extrusion Production Line:

| Model | TLJ500 | TLJ630 | TLJ630U |

| Nominal diameter of extrusion wheel (mm) | 500 | 630 | 630 |

| Main motor power (kW) | 355 | 600 | 600 |

| Diameter of copper rod (mm) | 25 | 30 | 30 |

| Maximum width of product (mm) | 260 | 320 | 420 |

| Diameter of round rod product (mm)/Maximum aspect ratio (b/a) | 12~100 | 12~120 | 35 |

| Product cross-sectional area (mm2)/Copper strip thickness (mm) | 300~3200 | 600~6400 | 14~18 |

| Productivity (kg/h) | 1800 | 2800 | 3500 |

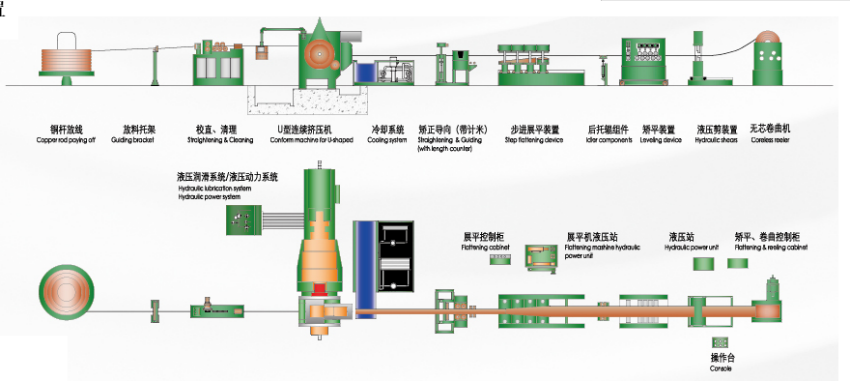

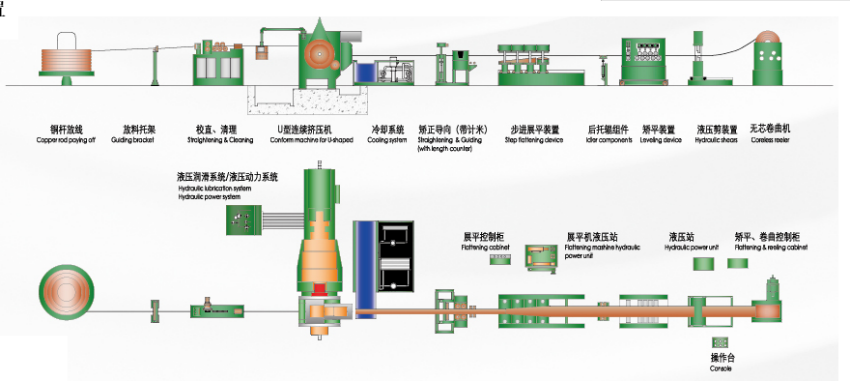

Production line layout of Copper Strip Continuous Extrusion Production Line:

Our technical support:

Customer demand is our service content. We have Copper strip continuous extrusion production line to produce all the products. We attach great importance to pre-sales service, strive to achieve personalized customization, and meet customers' needs for extruding new materials and producing new Copper Casting Machines using continuous extrusion technology. To this end, the Konform R&D Center is equipped with a complete set of test equipment from 250 to 630, which can carry out process tests in advance according to customer requirements, so that customers can eliminate doubts and launch new projects with peace of mind.

We have a high-quality after-sales service team with rich professional knowledge and practical experience, provide customers with technical advice around the clock, and solve various problems of customers on site.