Uses of Aluminum Alloy Continuous Casting And Extrusion Production Line:

Casting production line is mainly used to produce coils and wires such as aluminum strontium alloy and aluminum titanium boron alloy. Our casting production line can directly transform the molten aluminum alloy liquid into continuous plates or wires through the continuous casting and extrusion process, making the production process simpler and more efficient. Casting production line can also improve the density and surface quality of the material, reduce defects such as pores and inclusions, and save a lot of energy and labor costs. The use of aluminum alloy continuous casting production line can not only meet the needs of large-scale and high-quality production, but also adjust the alloy composition, size specifications, etc. According to the requirements of different customers. The entire set of equipment of our aluminum alloy continuous casting production line is easy to operate and has a high degree of automation. The coils and wires produced are of stable quality and good dimensional consistency. They are suitable for application in many industries such as automobiles, aviation, electricity, and construction.

Specifications of Aluminum Alloy Continuous Casting And Extrusion Production Line:

| Model | CCE400 | CCE500 |

| Diameter of crystallizer wheel of caster (mm) | 1200 | 1400 |

| Diameter of crystallization wheel (rpm) | 2.5 ~ 3.7 | 1.6 ~ 2.3 |

| Sectional area of ingot (mm2) | 730 | 1000 |

| Output speed of ingot (m/min) | 8.5 ~ 12.7 | 7.2 ~ 10.2 |

| Nominal diameter of extrusion wheel (mm) | 400 | 500 |

| Extruder power (kw) | 250 | 400 |

| Product diameter (mm) | 8 ~ 12 | 8 ~ 15 |

Yield (kg/h)

| 700 | 900 |

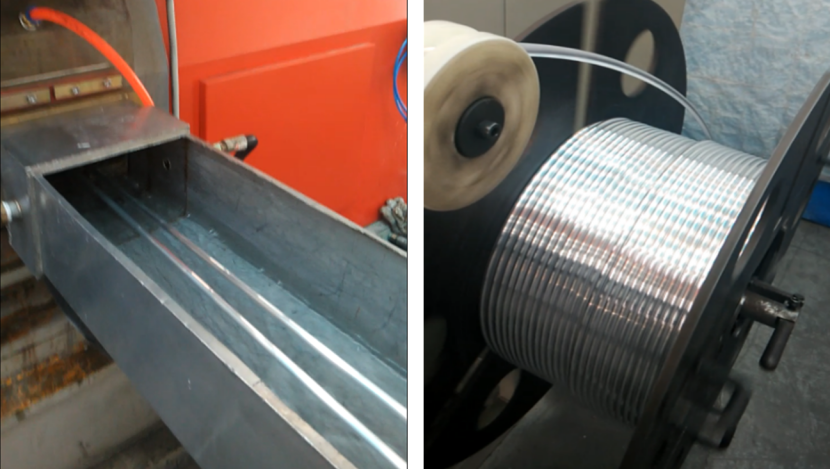

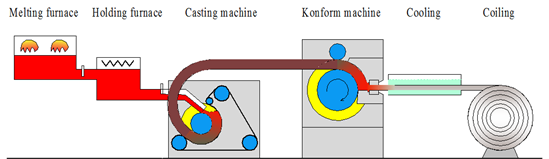

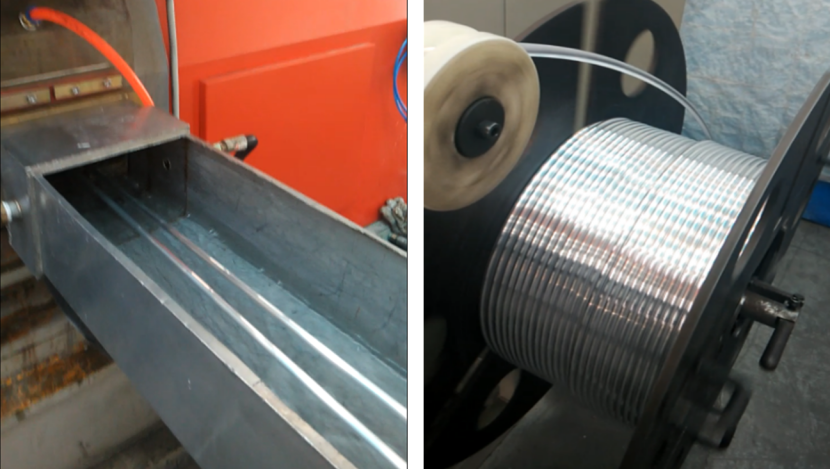

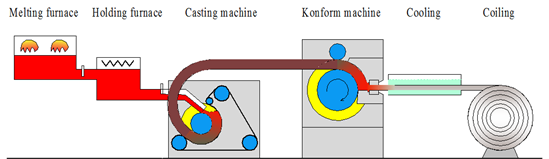

Production line layout of Aluminum Alloy Continuous Casting And Continuous Extrusion Production Line:

About our corporate values:

Integrity is the instant of Konform. It is not only the professional ethics of business operation, but also the core value of our life. We treat every customer, partner and employee honestly, strictly abide by the contract, and use the highest standards of public morality and social ethics. Always review and standardize our business conduct.

Look forward to working with you!

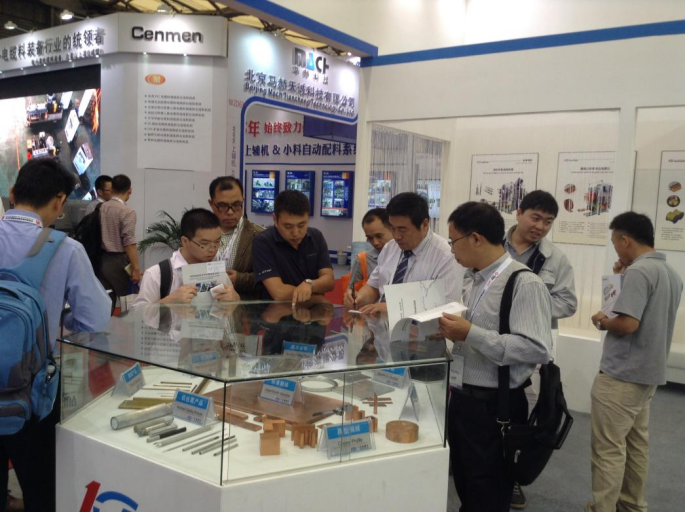

Our technical support:

Customer demand is our service content. We attach great importance to pre-sales service, strive to achieve personalized customization, and meet customers' needs for extruding new materials and producing new products using continuous extrusion technology. To this end, the Konform R&D Center is equipped with a complete set of test equipment from 250 to 630, which can carry out process tests in advance according to customer requirements, so that customers can eliminate doubts and launch new projects with peace of mind.

We have a high-quality after-sales service team with rich professional knowledge and practical experience, provide customers with technical advice around the clock, and solve various problems of customers on site.

Our advantages: advanced manufacturing, scientific management

The casting production line uses advanced processing methods and strict process standards in the manufacturing process to ensure the quality and long service life of the equipment. Our aluminum alloy continuous casting production line is fully debugged before leaving the factory to ensure that there are no defects when it is delivered to customers and that it operates stably and reliably. We have established a strict supply chain management system. All raw materials and supporting parts of the aluminum alloy continuous casting and extrusion production line are provided by well-known domestic and foreign companies, and all electrical components are selected from first-class brands to ensure that the overall performance of the equipment is superior and the quality of details is excellent. Therefore, our casting production line not only has high production efficiency and good product consistency, but also is easy to maintain and has a low failure rate during use, which can bring higher production capacity and better economic benefits to customers.