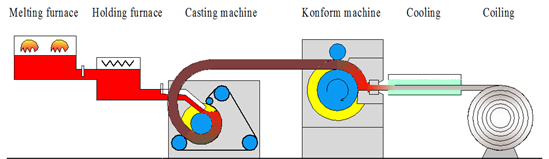

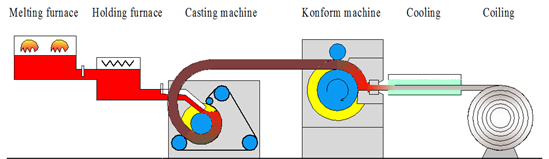

Introduction of aluminum continuous casting and extrusion line:

Aluminum continuous casting and extrusion line is a set of efficient production equipment integrating aluminum and aluminum alloy material smelting, continuous casting and continuous extrusion. Our aluminum continuous casting and extrusion line simplifies the process flow and reduces energy consumption by directly continuous casting aluminum liquid into billets and continuously extruding them. Our aluminum continuous extrusion production line has a reasonable design and compact structure, and is suitable for the production of various intermediate alloy coils and wires such as aluminum strontium, aluminum titanium boron, etc.

Advantages of aluminum continuous extrusion production line:

Aluminum continuous extrusion production line adopts advanced processing technology and strict manufacturing standards, with stable quality and long service life. Aluminum continuous extrusion production line will be fully debugged before leaving the factory, and customers can directly put it into production. In addition, all raw materials and key components of our aluminum continuous extrusion production line are from well-known domestic and foreign suppliers, and the electrical system adopts international first-class brands to ensure efficient, safe and reliable operation.

Uses of Continuous Casting And Continuous Extrusion Production Line for Aluminum:

Production of aluminum strontium, aluminum titanium boron and other intermediate alloy gold coils, wire rods

Specifications of Continuous Casting And Continuous Extrusion Production Line for Aluminum:

| Model | CCE400 | CCE500 |

| Diameter of crystallizer wheel of caster (mm) | 1200 | 1400 |

| Diameter of crystallization wheel (rpm) | 2.5 ~ 3.7 | 1.6 ~ 2.3 |

| Sectional area of ingot (mm2) | 730 | 1000 |

| Output speed of ingot (m/min) | 8.5 ~ 12.7 | 7.2 ~ 10.2 |

| Nominal diameter of extrusion wheel (mm) | 400 | 500 |

| Extruder power (kw) | 250 | 400 |

| Product diameter (mm) | 8 ~ 12 | 8 ~ 15 |

Yield (kg/h)

| 700 | 900 |

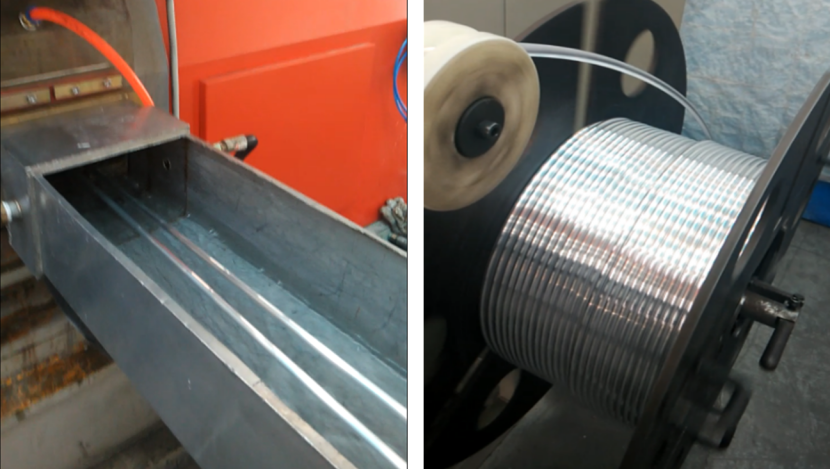

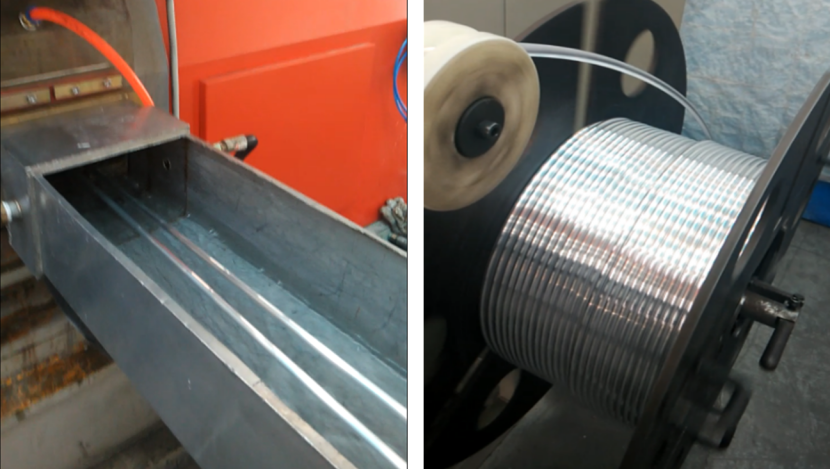

Production line layout of Continuous Casting And Continuous Extrusion Production Line for Aluminum:

About our corporate values:

Integrity is the core concept that konform always adheres to. For us, integrity is not only the professional ethics that must be followed in business operations, but also the basic principle of our conduct and work, and the core value in the hearts of every konform person. In the communication and cooperation with every customer, partner and employee, we always uphold a frank and trustworthy attitude, conscientiously fulfill every promise, strictly abide by the contractual agreement, and never do anything that damages our reputation. Whether in terms of product quality, delivery time or after-sales service, we hold ourselves to the highest industry standards and the strictest social ethics to ensure that every link is open, transparent, fair and just. We always take customer needs as the guide, cooperation and win-win as the goal, respect the interests of every partner, focus on communication and understanding, and win the trust and support of customers with practical actions. In addition, konform will continue to reflect on itself and standardize, and strive to be responsible to the society, customers and employees by continuously improving the management system and improving the service level, so as to truly achieve long-term sustainable development, adhere to integrity as the basis, continuously optimize ourselves, improve professional capabilities, and work hand in hand with friends from all walks of life to create a better future. Sincerely look forward to working with you!

Dalian Konform Service

Customer service is the first point of contact for many customers often leaves last impression. It plays a vital role in building trust and maintaining relationship with customers. When customers encounter a problem or have a question, prompt and efficient assistance from customer service representatives can alleviate their concerns and reassure them that the business cares about their satisfaction. Excellent customer service can lead to increased customer retention and referrals. Customer service can provide valuable insights into customer needs and preferences.

We have a strong after-sales service team(about 30 mechanical and electrical engineers) with rich professional knowledge and practical experience to provide commissioning, maintenance, and repair service to our customers all over the world. They can reach to customer ‘s plant at very short time, If they need, we can provide online support or remote control for 24 hours.