The main uses of High speed Aluminum wire extrusion machine are:

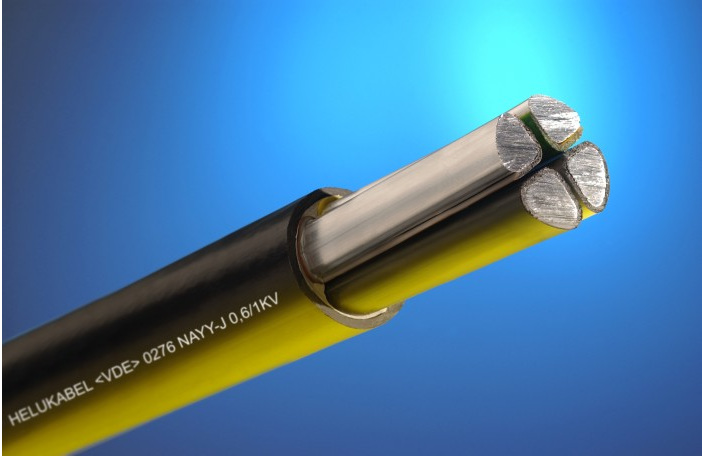

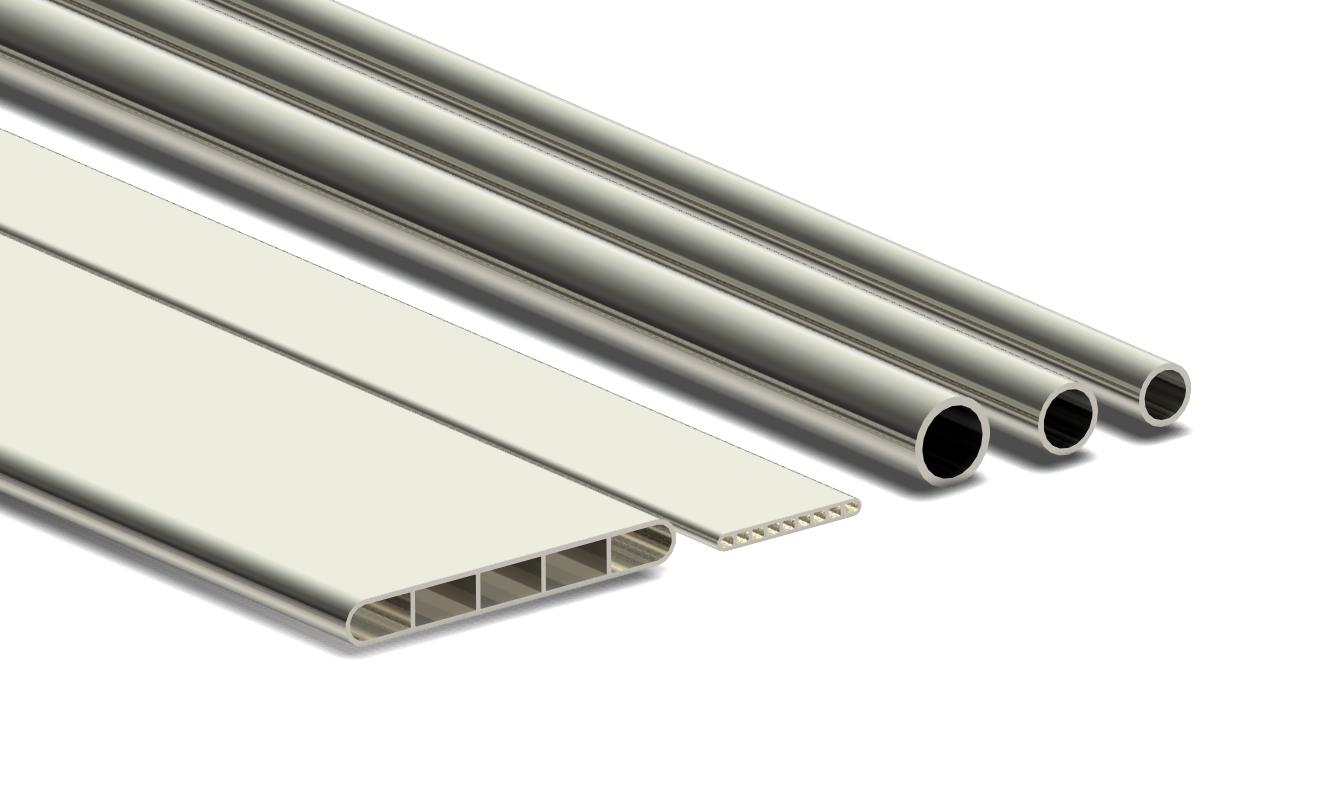

High speed Aluminum wire extrusion machine is mainly used for the continuous extrusion production of high-precision aluminum wires, with the advantages of fast production speed, high surface finish, and good dimensional consistency. Continuous extrusion production line for aluminum busbar is widely used in power transmission, cable conductors, automotive wiring harnesses, electronic components, aerospace, and construction. Aluminum continuous extrusion machine can be used to produce aluminum conductors, magnetic wires, welding wires, and other special aluminum wire products with high precision and performance requirements to meet the needs of large-scale, high-efficiency modern production.

Specifications of High speed Aluminum wire extrusion machine:

| Model | LLJ300H |

| Nominal diameter of extrusion wheel (mm) | 300 |

| product category | Aluminium wire&busbar |

| Main motor power (kW) | 110 |

| Aluminum rod diameter (mm) | 9.5 |

| Maximum width of product (mm) | 30 |

| Product cross-sectional area (mm2) | 5~150 |

| Productivity (kg/h) | 280 |

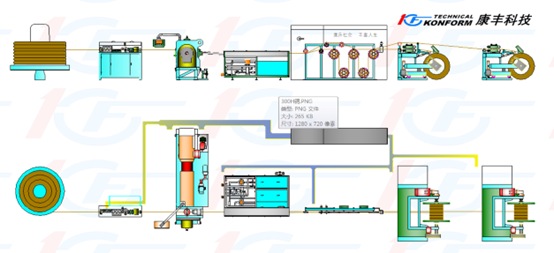

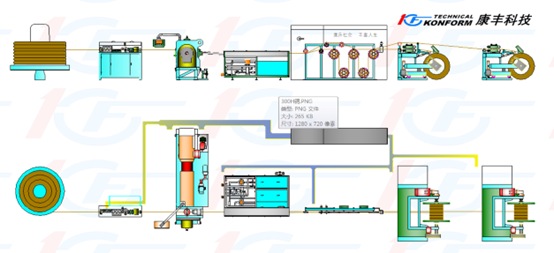

Layout of the Continuous Extrusion Production Line for Aluminum Busbar:

The overall layout of aluminum continuous extrusion machine is compact and reasonable, covering the complete process from raw material feeding to finished product winding. The entire aluminum continuous extrusion machine production line generally includes a conductor feeding system, a continuous extrusion main machine, a cooling system, a traction device, a cut-to-length cutting equipment, and a receiving system. The modules of aluminum continuous extrusion machine are connected through an automatic conveying system for efficient collaboration to ensure a continuous and stable production process. The control system is centrally located on the operating table, and full-process monitoring and parameter adjustment are achieved through PLC and touch screen. Aluminum continuous extrusion machine reserves a remote module interface for remote diagnosis and maintenance, greatly improving the level of intelligent management. The layout of aluminum continuous extrusion machine saves space and facilitates operation and maintenance, and is suitable for aluminum busbar extrusion processing needs of various sizes.

Product feature of high speed aluminum wire extrusion machine:

1. High speed Aluminum wire extrusion machine has unique cooling system, smart die design, high extrusion wheel speed.

2. Mechanical shoe lock system of continuous extrusion production machine has high reliability and stability, energy saving.

3. Automatic short rod feeding system to save labor.

4. Constant tension take up system to ensure stability of product size.

5. Automatic caterpillar tractor to help operator change the bobbin.

6. Continuous extrusion production machine use integrated hydraulic system for space occupancy, no oil leakage.

7. The aviation plugs of continuous extrusion production machine for cable connection to help cable connecting.

8. Industrial cloud data system and production date of continuous extrusion production machine are traceable.

Our Advantage:

Status in the industry: We are world leader, sales account for 50% of the world's totally in continuous extrusion production line for aluminum busbar industry.

Machine feature: All the data monitoring and remote maintenance support. The new model continuous extrusion production line for aluminum busbar saves 20% of energy per ton, increase production by 80% and save 60% space compared to traditional models. It has high precision and long service life, only need one operator to control.

R&D: Separate R&D team. Improve and develop the machine annually. Have an independent laboratory to conduct on-site product testing based on the special materials provided by the customer.

Purchased part: All the electrical components are world famous brand, such as Siemens and ABB. The gearbox and coupling are the best in China.

Aftersales service: 30 maintenance engineers travel around the world for continuous extrusion production machine installation and maintenance frequently. They can reach to customer's plant at very short time, If they need. Provide online support or remote control for 24 hours.

Dalian Konform Service:

Customer service is the first point of contact for many customers often leaves last impression. It plays a vital role in building trust and maintaining relationship with customers. We have a strong after-sales service team(about 30 mechanical and electrical engineers) with rich professional knowledge and practical experience to provide commissioning, maintenance, and repair service to our customers all over the world. They can reach to customer's plant at very short time, If they need, we can provide online support or remote control for 24 hours.