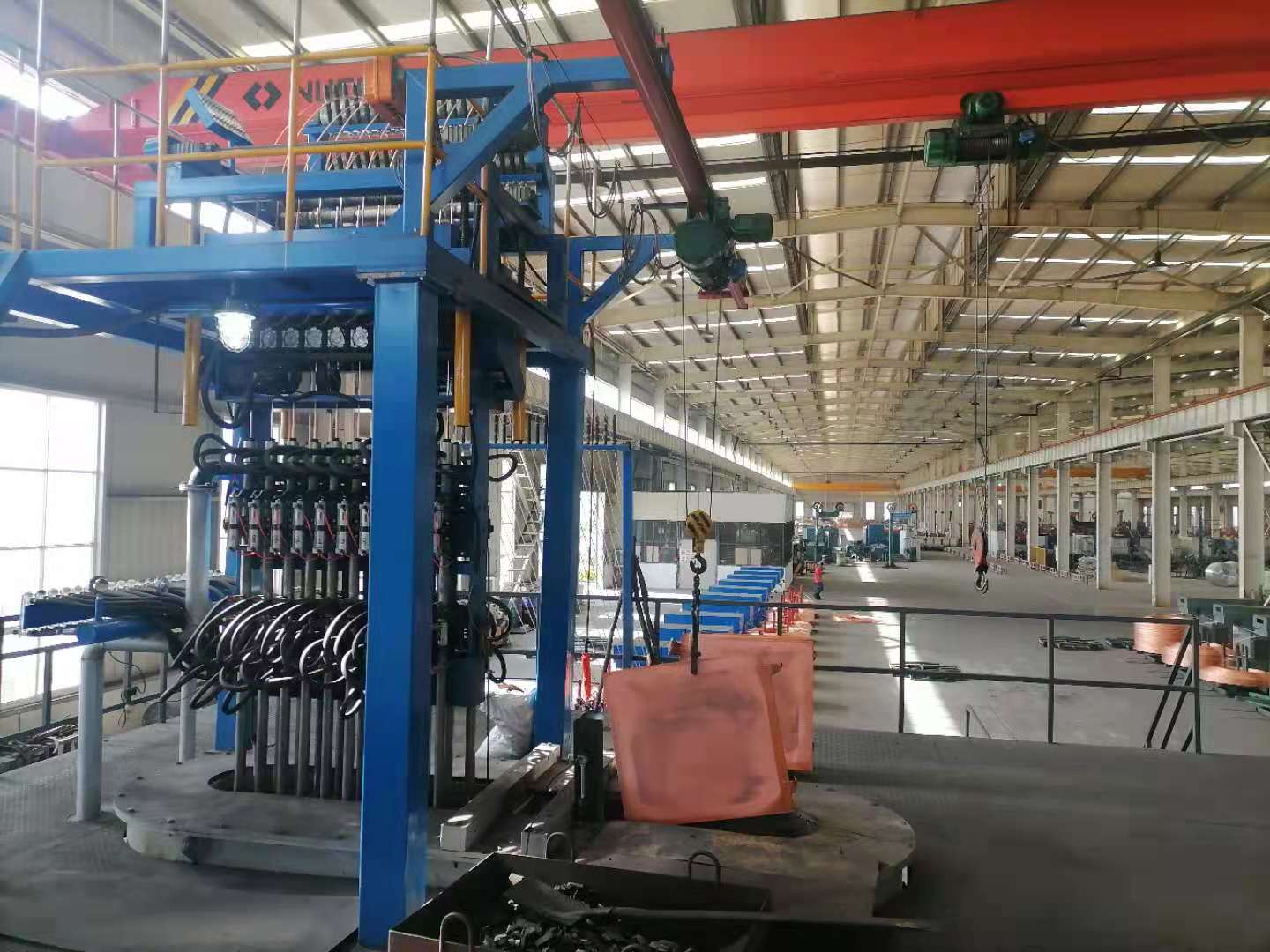

Introduction of cathode copper continuous casting machine:

Copper rod up continuous caster is a modern casting equipment that adopts the upward continuous casting process and integrates the unique technology newly developed by Konform. The copper rod upward continuous casting machine can produce high-purity copper rods with uniform diameter, dense interior and extremely low oxygen content by continuous upward drawing. It is widely used in wire and cable, electronic and electrical, aerospace and other fields, and can operate stably and efficiently.

Features of continuous casting machine for copper rod:

1. The smelting system of our cathode copper continuous casting machine adopts w-type energy-saving induction furnace, which can reduce the energy consumption of molten copper per ton from more than 400 kwh to less than 320 kwh.

2. The induction sensor structure in the furnace of the copper rod up continuous caster we produce has been optimized and can be disassembled and replaced independently, reducing maintenance costs without affecting the working operation.

3. Our copper rod upward continuous casting machine adopts advanced hollow core control technology, which can control the hollow core oxygen content of the copper rod within 10ppm, improving the conductivity and mechanical properties of the copper rod.

Technical parameter of copper rod upward continuous casting machine:

model | SYLZ-10000T |

annual output | 10000 tons(annually uninterrupted) |

molten copper rate | ≥1250kg/h |

strands quantity | 20 strands |

pulling pitch | 1-5mm adjustable |

pulling speed | 0.3~3.2 m/min |

working temperature | 1150° |

maximum temperature | 1300° |

take-up machine | 10 sets |

rod diameter | Φ8-30 (customize) |

inductor furnace style | combined style joint furnace |

type of drive | double servo motor drive |

take-up type | automatic take-up controlled by computer |

coil weight | more than 3 tons |

continuous casting machine | PLC controlled, touch screen |

Running capacity | 450KW |

Installation capacity | 700KVA |

Power consumption per ton of molten copper | 290KWH |

Application scenarios of continuous casting machine for copper rod:

Our cathode copper continuous casting machine is suitable for the production of copper core materials for power cables, communication cables, control cables, etc. In the electronics manufacturing industry, copper rod up continuous caster is suitable for integrated circuit lead frames, connectors, terminals, etc. The copper rod upward continuous casting machine is also suitable for precision hardware processing, high-end equipment manufacturing and other industries.

Precautions for copper rod upward continuous casting machine:

During installation and commissioning, the continuous casting machine for copper rod should be constructed according to the provided installation drawings and process instructions, and each system should be correctly connected. Before the cathode copper continuous casting machine is officially powered on, insulation and grounding tests should be performed on each cable and connector. During use, raw materials that meet the standards should be controlled. During the operation of the continuous casting machine for copper rod, the cooling water system should ensure stable operation. Long-term use of the cathode copper continuous casting machine requires regular replacement of damaged components.

About us:

Founded in 1993, Konform is a leading global supplier of continuous extrusion technology and equipment. The company's research and development history in this field can be traced back to 1984. For more than 30 years, we have provided customers in the fields of non-ferrous metal processing and cable manufacturing with efficient continuous extrusion, continuous coating and continuous sheathing solutions. Based on more than 30 patented technological innovations, Dalian Konform has developed 24 different models of equipment in three major product categories (continuous extrusion, continuous coating and continuous sheathing of copper and aluminum).