Product introduction of Equipment for high voltage cable sheathing:

Equipment for high voltage cable sheathing is designed to provide reliable and precise metal sheaths for high-voltage cables, ensuring excellent electrical insulation performance and mechanical protection. Equipment for high voltage cable sheathing supports the use of materials such as lead or aluminum to achieve seamless and highly sealed sheath structures, and is widely used in underground cables and submarine cables. Equipment for HV and EHV cable sheathing is equipped with an automatic control system that can accurately adjust the temperature, pressure and extrusion speed to ensure uniform sheath wall thickness and firm adhesion. Continuous Extrusion Machine for ACS Wire has stable operation and high production efficiency, and is suitable for the manufacture of cable sheaths of large lengths and large quantities, fully meeting the strict requirements of the power industry for high-performance sheathing processes.

Product application of Continuous Extrusion Machine for ACS Wire:

Continuous Extrusion Machine for ACS Wire is widely used in power transmission, underground power transmission projects, submarine cable laying and industrial energy systems. Equipment for HV and EHV cable sheathing is suitable for providing strong and corrosion-resistant metal sheaths for high-voltage and ultra-high-voltage cables, effectively preventing damage to the cables by the external environment and improving the safety and service life of the cable system. In long-distance power transmission projects, urban power grid construction and power station projects, equipment for HV and EHV cable sheathing plays a key role and is an important equipment to ensure the stable operation of high-voltage cables.

Specifications of Continuous Extrusion Machine for ACS Wire:

| Model | SLB350 | SLB400 |

| Extrusion wheel diameter (mm) | 350 | 400 |

| Motor power (kw) | 200 | 315 |

| Aluminum rod diameter (mm) | 2 x 9.5 | 2 x 12 |

| Wire diameter (mm) | 3~7 | 3~7 |

| Electrical conductivity (IACS) | 14~40% | 14~40% |

| Maximum production line speed (m/min) | 180 | 180 |

Product advantages of Machinery for Power Cable:

Machinery for Power Cable has many significant advantages, including high-precision automatic control system to ensure uniform thickness and strong sealing of the sheath; Machinery for Power Cable has stable operation, suitable for long-term continuous operation, and improves overall production efficiency; it is compatible with a variety of metal materials and adapts to different application requirements; Machinery for Power Cable has good energy-saving performance and low maintenance costs, helping enterprises reduce operating expenses.

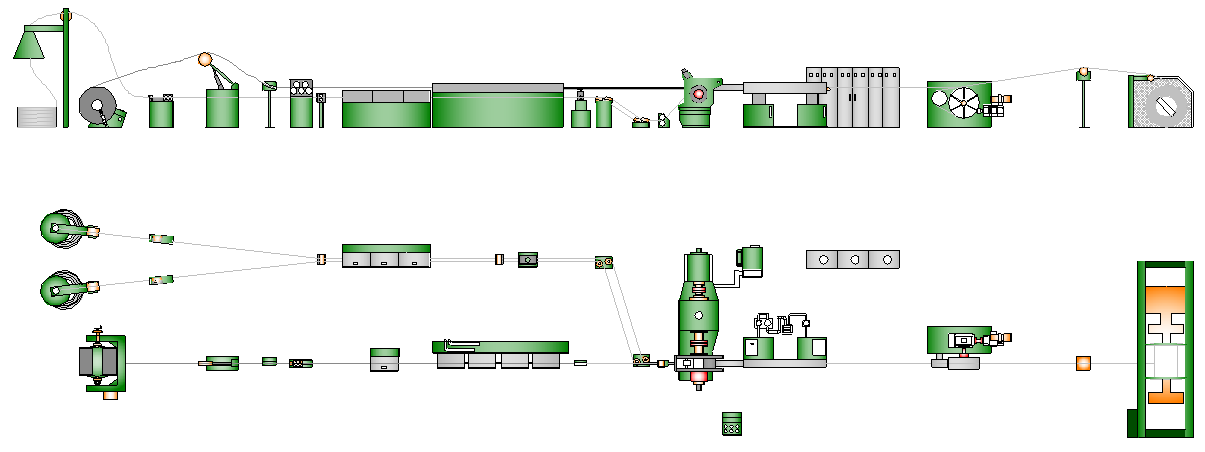

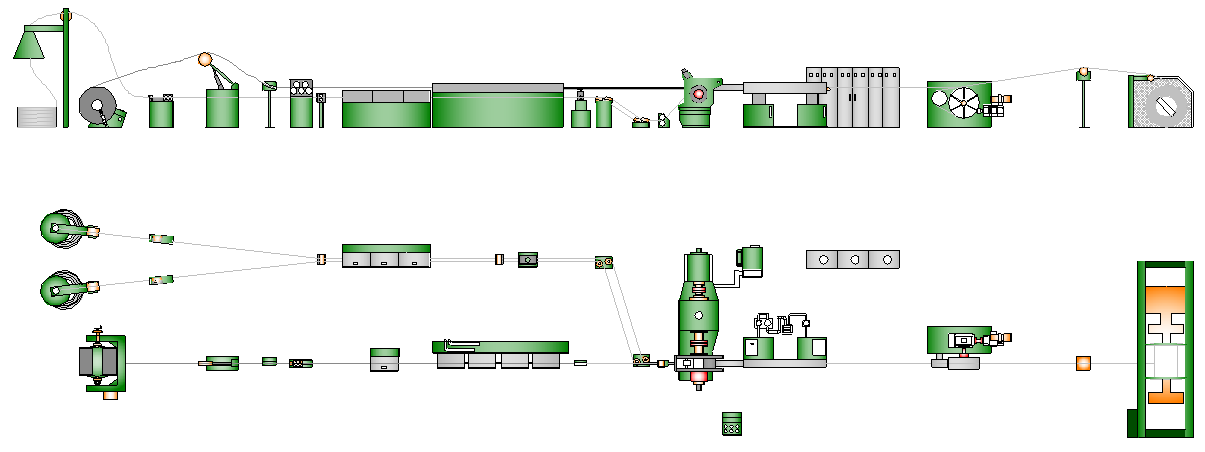

Production line layout of Machinery for Power Cable:

Our certificate of Machinery for Power Cable:

FAQs:

1. What types of sheath materials are suitable for Equipment for high voltage cable sheathing?

Equipment for high voltage cable sheathing can be applied to a variety of metal materials, such as lead, aluminum and its alloys, to meet the sheath requirements of different high-voltage cable projects.

2. Does Equipment for HV and EHV cable sheathing support continuous production of long-distance cable sheaths?

Yes, Equipment for HV and EHV cable sheathing supports continuous operation and is suitable for the production of hundreds or even thousands of meters of cable sheaths, especially for large-scale projects.

3. Does Machinery for Power Cable have a high maintenance frequency?

Machinery for Power Cable has a reasonable structure and stable operation. The maintenance frequency is low under normal use. It only needs regular inspection and maintenance to keep it in good condition.

About us:

Dalian Konform Technology co., Ltd. is the first in my country to successfully develop three series of 250, 300, 350, 400, 500, 550 and 630 series and 24 specifications of copper and aluminum continuous extrusion and coating complete sets with more than 30 patented technologies equipment. Passed ISO9001 quality system certification and EU safety CE certification, it has supplied more than 1,500 production lines for domestic and foreign users, and its products are sold in 29 domestic provinces, municipalities and autonomous regions, and exported to 52 in Asia, Europe, America, Australia and Africa. country and region.