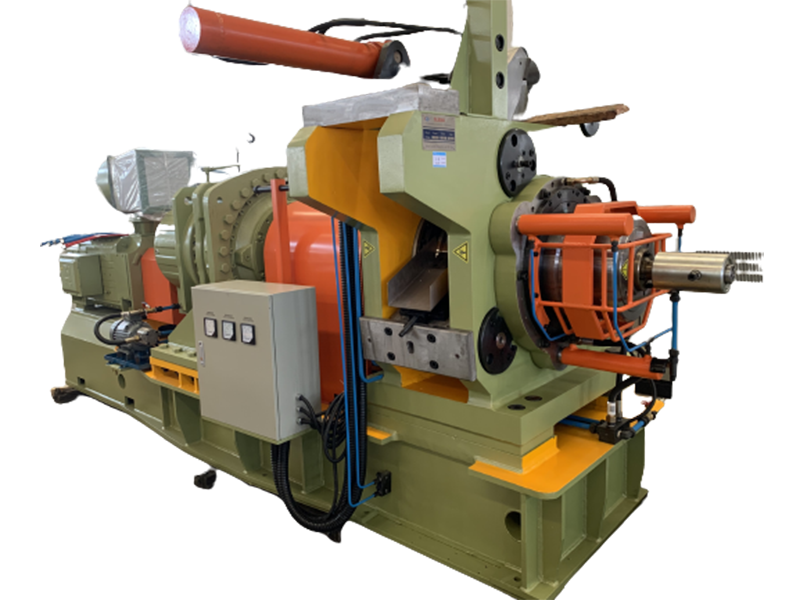

Introduction of Continuous Extrusion Machine for ACS wire:

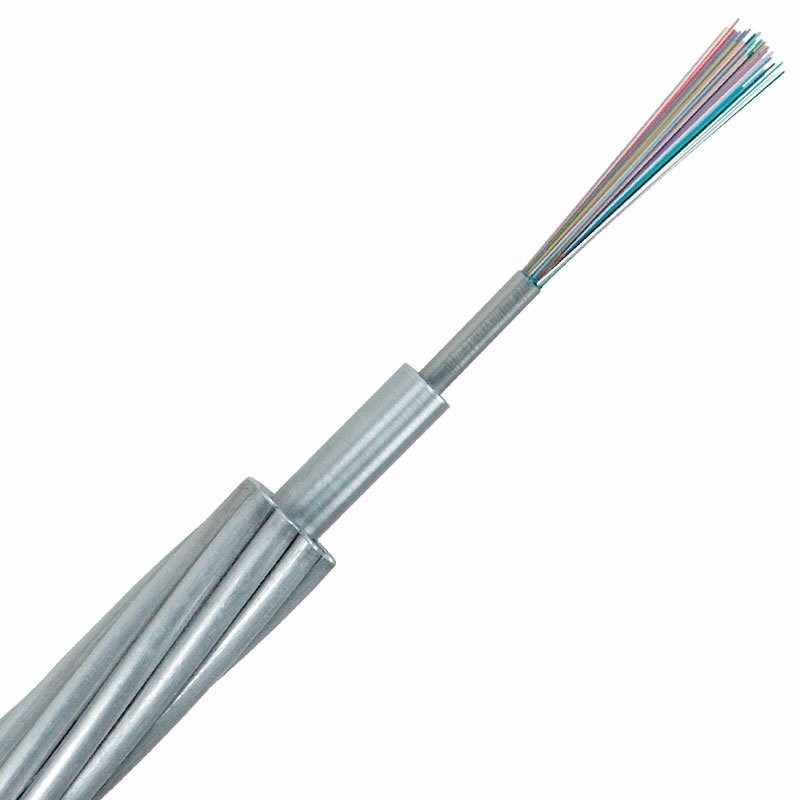

The ACS Wire Continuous Extruder we produce is specially designed for efficient and stable production of aluminum-clad steel wires. It has excellent extrusion uniformity and aluminum-steel bonding firmness, and can accurately control the wire diameter. ACS Wire Continuous Extruder adopts advanced automation systems and energy-saving technologies to greatly improve production efficiency and reduce operating costs. ACS Wire Continuous Extruder is widely used in communications, power transmission, overhead ground wires and other fields. It has stable product quality and high reliability. It is an important equipment for modern aluminum-clad steel wire manufacturing. It can produce aluminum-clad steel wire with conductivity of 14-40%.

Specifications of Continuous Extrusion Machine for ACS Wire:

| Model | SLB350 | SLB400 |

| Extrusion wheel diameter of Continuous Extrusion Cladding (mm) | 350 | 400 |

| Motor power of Continuous Extrusion Cladding (kw) | 200 | 315 |

| Aluminum rod diameter of Continuous Extrusion Cladding (mm) | 2 x 9.5 | 2 x 12 |

| Wire diameter of Continuous Extrusion Cladding (mm) | 3~7 | 3~7 |

| Electrical conductivity of Continuous Extrusion Cladding (IACS) | 14~40% | 14~40% |

| Maximum production line speed of ACS Wire Continuous Extruder(m/min) | 180 | 180 |

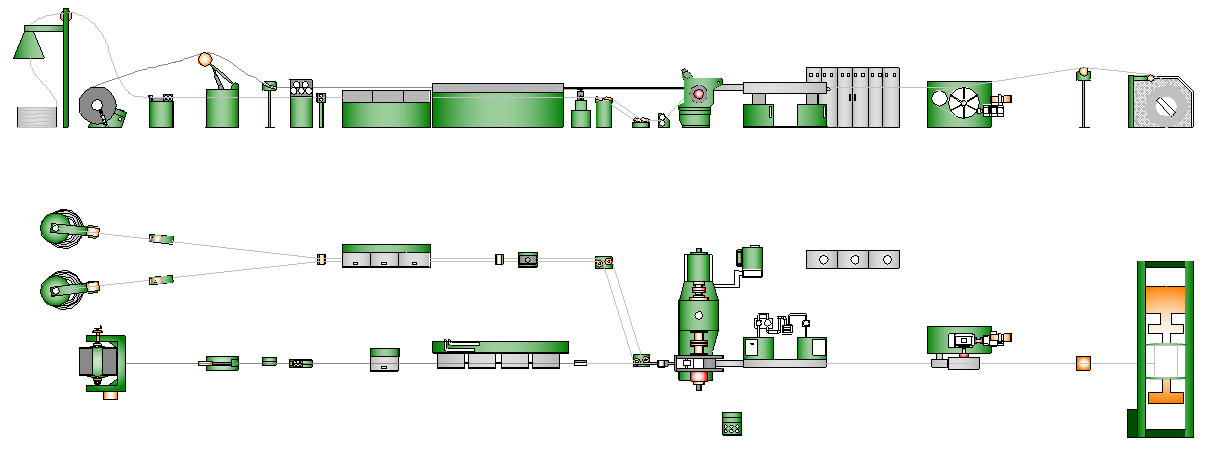

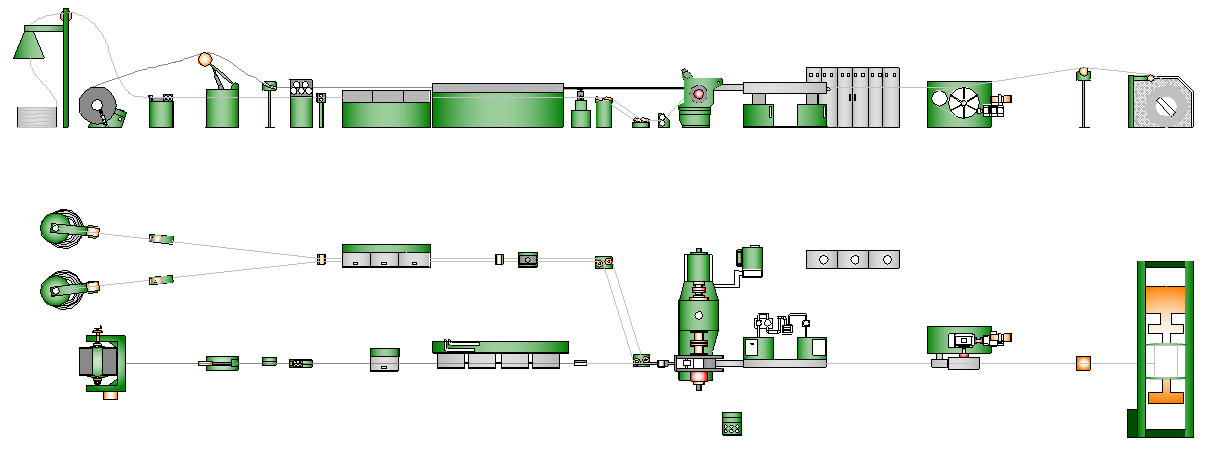

Production line layout of Continuous Extrusion Machine for ACS Wire:

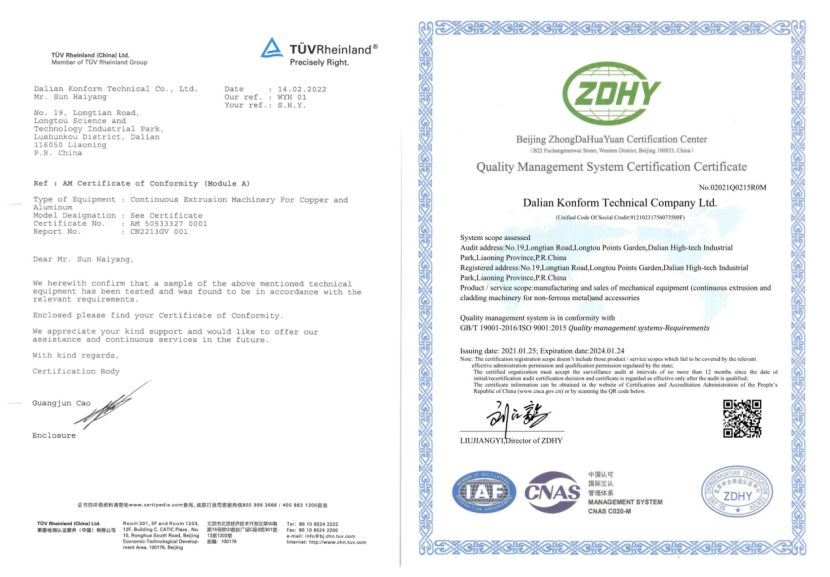

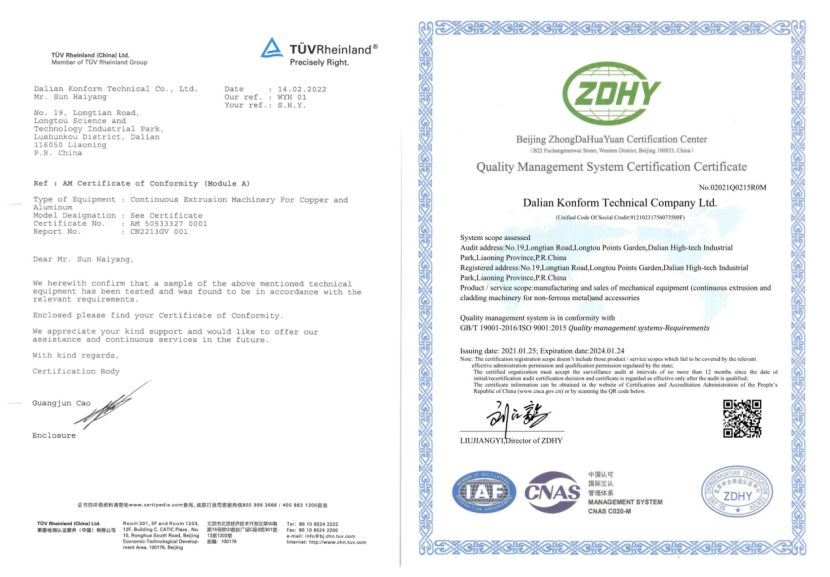

Our certificate:

Company Profile

Dalian Konform Technology Co., Ltd. is a pioneer in China in the development of complete aluminum continuous cladding production lines and ACS wire continuous extruders. The company has independently developed three major equipment series covering models 250, 300, 350, 400, 500, 550, and 630, totaling 24 specifications, and holds over 30 patented technologies. These advanced solutions are designed for continuous extrusion and coating of copper and aluminum materials.

Konform has passed both ISO9001 quality management system certification and the EU CE safety certification. To date, the company has delivered more than 1,500 production lines to customers worldwide. Its aluminum continuous cladding production lines and ACS wire continuous extruders are widely used across 29 provinces, municipalities, and autonomous regions in China, and exported to 52 countries and regions throughout Asia, Europe, the Americas, Australia, and Africa. The company continues to lead the industry with cutting-edge technology and a strong commitment to global service.

Our Advantage

Konfrom is a global leader in the continuous extrusion industry, with a market share of over 50%. Core products include Aluminum Continuous Cladding Production Line and Continuous Extrusion Machine for ACS Wire, etc., with full-process data monitoring and remote maintenance functions. Compared with traditional models, the new generation of equipment saves 20% energy, increases production by 80%, reduces land occupation by 60%, is easy to operate, and only requires one person to control.

We have an independent R&D team and laboratory, support on-site testing based on customer materials, and continuously promote equipment optimization and upgrading. Key electrical components are all selected from international brands such as Siemens and ABB, and the reduction box and coupling adopt domestic top configuration to ensure stable and efficient operation of the equipment.

In terms of after-sales, 30 engineers are stationed around the world to provide installation and maintenance services, and support 7×24 hours online remote technical support to ensure efficient and continuous operation of customer equipment.

Konform Service

We prioritize customer needs by offering full pre-sale technical support and collaboration. Our lab, equipped with the complete Aluminum Continuous Cladding Production Line range (models 250–800), enables testing of new products and materials based on customer requirements. This ensures tailored solutions and builds strong customer confidence before ordering.

Our global after-sales service team, consisting of around 30 experienced mechanical and electrical engineers, provides rapid on-site support for installation, commissioning, and maintenance of systems such as the Continuous Extrusion Machine for ACS Wire. We also offer 24/7 online assistance and remote troubleshooting to ensure uninterrupted production.