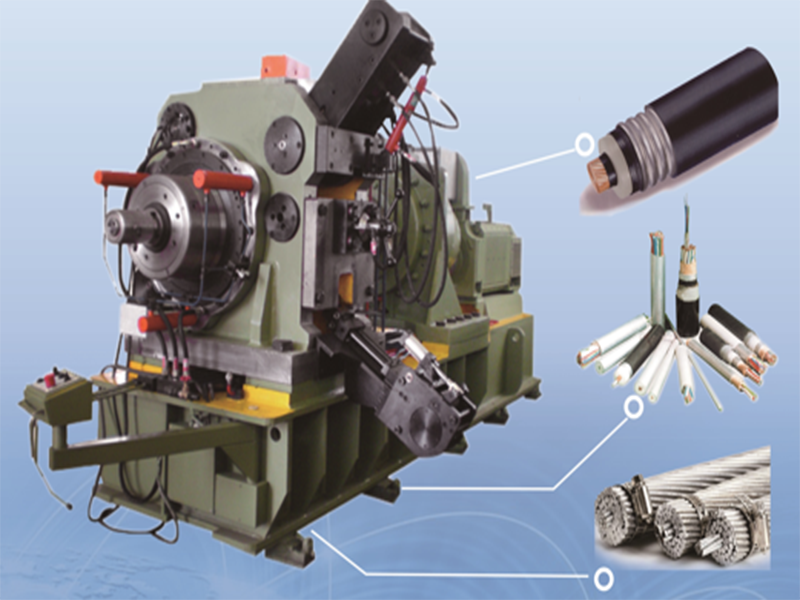

Product Introduction of Aluminium clad steel Wire extruder:

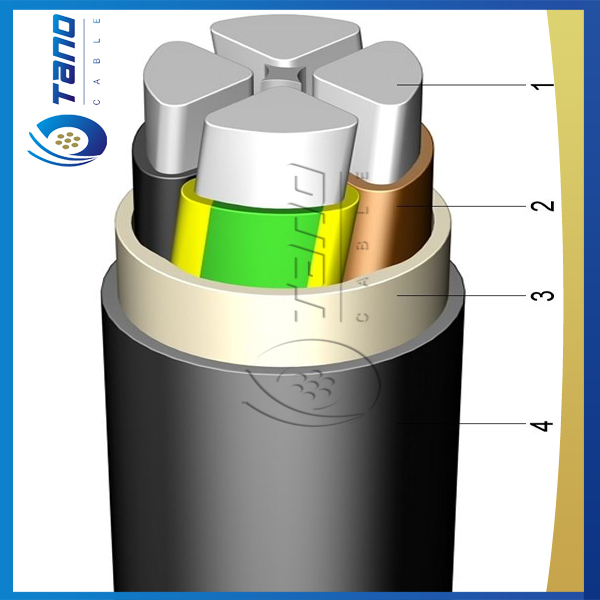

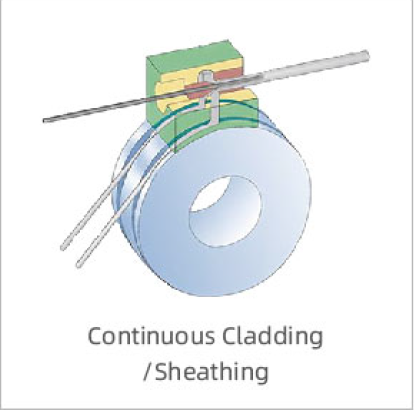

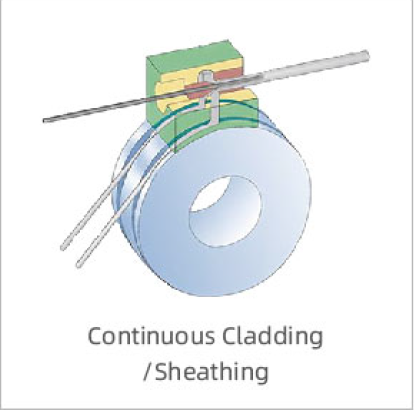

The Continuous Cladding & Sheathing Machine for Cable operates on a principle similar to continuous extrusion. Using a tangential die layout, the extrusion wheel feeds two metal rods into the cavity. Under high temperature and pressure, the material either bonds metallurgically with the wire core to form a protective layer or is extruded through the gap between the mandrel and die to form a non-contact metal sheath.

For large-diameter cores, a double-wheel setup feeds four rods simultaneously, enabling higher efficiency. This technology is widely applied in Aluminum sheathing machines and Aluminium clad steel wire extruders, enhancing sheathing uniformity and productivity.

Use of aluminum sheathing machine for OPGW cable or OPGW extruder:

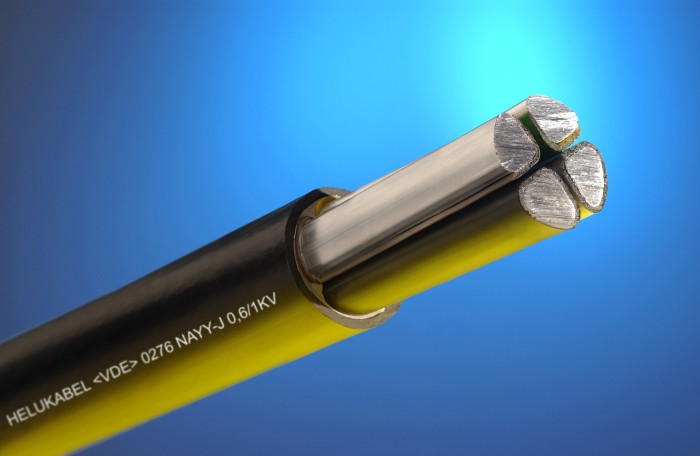

Continuous Cladding & Sheathing Machine for Cable is mainly used to produce aluminum clad steel wire (ACS wire), which is widely used in communications, power transmission, railway signals and other fields. By efficiently combining aluminum with steel core, Continuous Cladding & Sheathing Machine for Cable can provide good conductivity and corrosion resistance while ensuring high strength. Continuous Cladding & Sheathing Machine for Cable is particularly suitable for the manufacture of coaxial cables, overhead transmission lines and other application scenarios that require lightweight and high-strength conductors. It is an indispensable key equipment in modern cable manufacturing. Production of Aluminum sheathing machine, manufacture of aluminum sheaths for cables and optical cables, including cable television coaxial cables (CATV), optical fiber composite overhead ground wires (OPGW), communication signal cables, fire-resistant cables, and aluminum sheaths for extra-high voltage cables.

Specifications of Continuous Extrusion Machine for OPGW, Cable, CATV:

| Model | SLB350 | SLB400 |

| Extrusion wheel diameter of Aluminum sheathing machine (mm) | 350 | 400 |

| Motor power of Aluminum sheathing machine (kw) | 160 | 250 |

| Aluminum rod diameter of Aluminum sheathing machine (mm) | 2 x 9.5 | 2X9.5/2 x 12 |

| Core wire diameter of Aluminum sheathing machine (mm) | 4~28 | 8~46 |

| Sheath thickness of Aluminium clad steel Wire extruder (mm) | 0.6~3 | 0.6~3 |

| Maximum production line speed of Aluminium clad steel Wire extruder(m/min) | 60 | 60 |

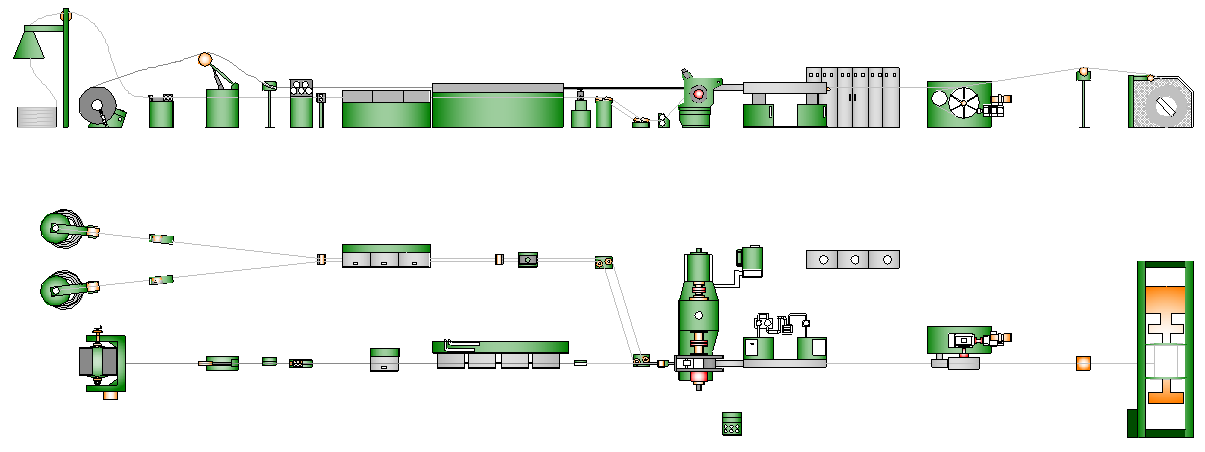

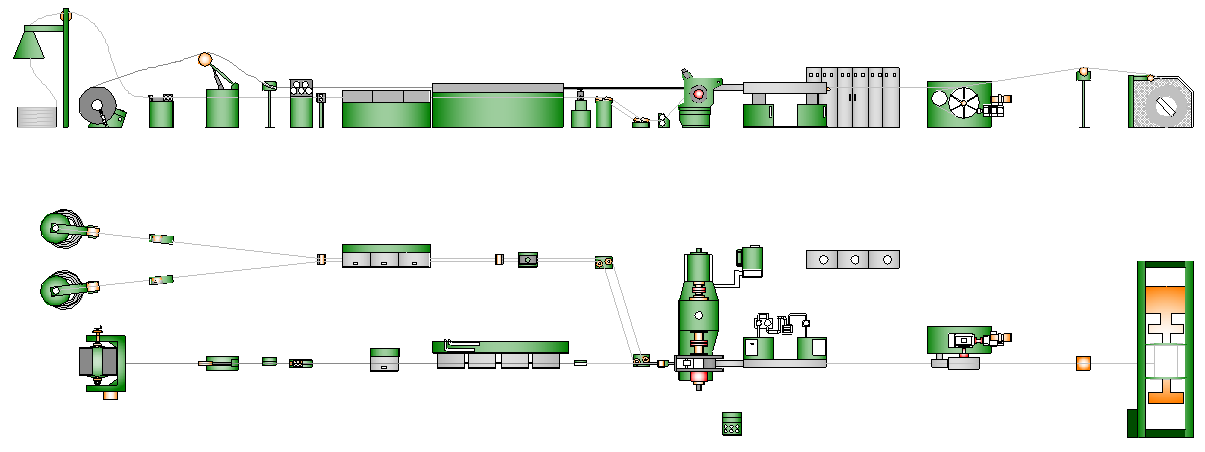

Production line layout of Aluminium clad steel Wire extruder for OPGW, Cable, CATV:

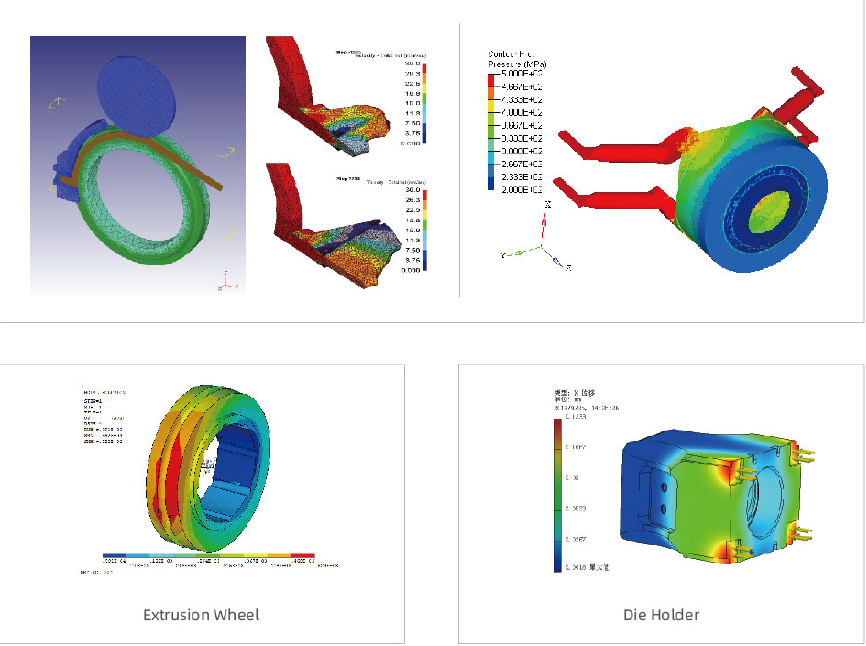

Konform Technology

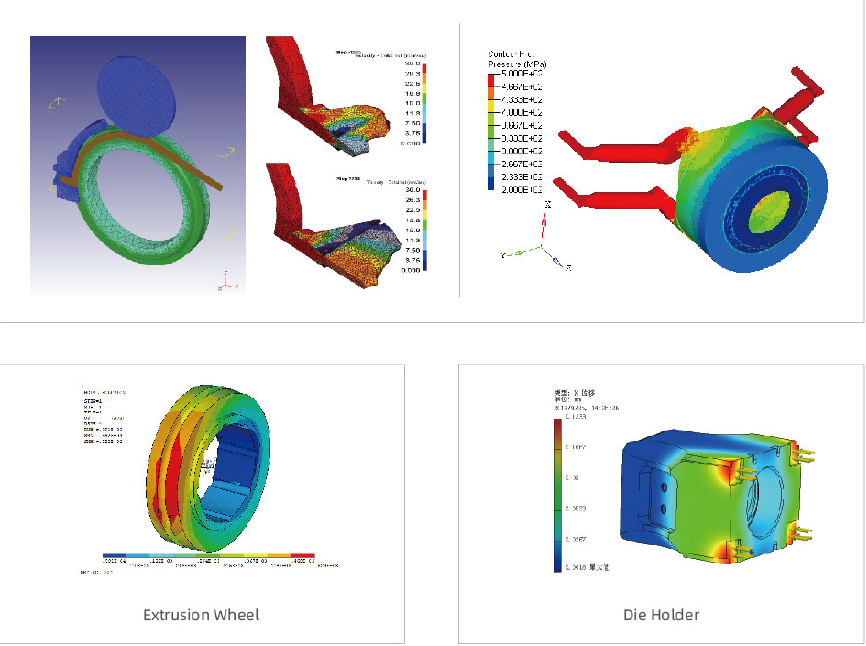

We apply the latest technological insights into nonferrous metal heat treatment to calculate key process parameters. By leveraging advanced numerical simulation software for plastic forming, we analyze the velocity, stress, and temperature distribution within the continuous extrusion deformation zone. This allows us to accurately assess equipment and tooling loads and ensure a robust design. The system also optimizes critical process variables—such as the extrusion wheel, rod material, chamber configuration, die structure, and cooling method—for each production step to achieve stable and efficient operation.

FAQs:

Q: What types of cables are suitable for Aluminium clad steel Wire extruder?

A: Aluminium clad steel Wire extruder is suitable for the coating and sheathing of various types of cables such as CATV cables, communication cables, signal cables and aluminum-clad steel core wires (ACS wires).

Q: Can one Aluminum sheathing machine process multiple raw materials at the same time?

A: Yes, Continuous Cladding & Sheathing Machine for Cable supports continuous coating operations of various metal raw materials (such as aluminum, copper and their alloys), and the extrusion wheel, mold and parameter settings can be replaced according to process requirements.

Q: Will the Aluminium clad steel Wire extruder coating process damage the cable core wire?

A: No. Aluminum sheathing machine adopts a non-contact sheathing process or a metallurgical combination process with the core wire to ensure that the core wire structure and conductive properties are not affected.

Q: Is Aluminum sheathing machine complicated to operate? How many people are needed to operate it?

A: Aluminium clad steel Wire extruder has a high degree of automation, intelligent monitoring and remote maintenance functions, and usually only one person is needed to complete the operation and monitoring of the entire line.

Q: How often is Aluminum sheathing machine maintained? Is there after-sales service support?

A: Aluminium clad steel Wire extruder is reliable in design and has a long maintenance cycle. At the same time, we provide 24-hour remote technical support and dispatch engineers around the world to provide installation, commissioning and maintenance services.