Product introduction of ACS Wire Extruder:

The ACS Wire Extruder we produce is designed to achieve efficient and stable composite coating process, and is suitable for the continuous coating production of steel core aluminum clad wire. ACS Wire Extruder adopts an intelligent control system with precise temperature control and real-time monitoring functions to ensure uniform coating and strong adhesion. Compared with traditional processes, the ACS Wire Extruder we produce can effectively improve production efficiency, reduce energy consumption, and greatly reduce the need for manual operation. It is an ideal high-performance production equipment for modern communications and power industries.

Use of Extrusion Machine for ACS Wire:

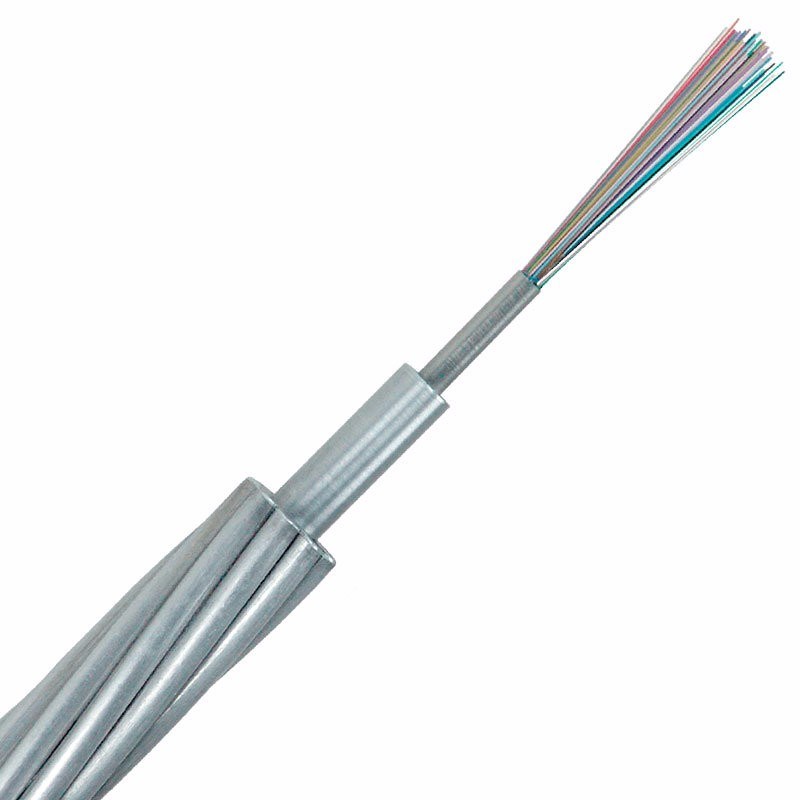

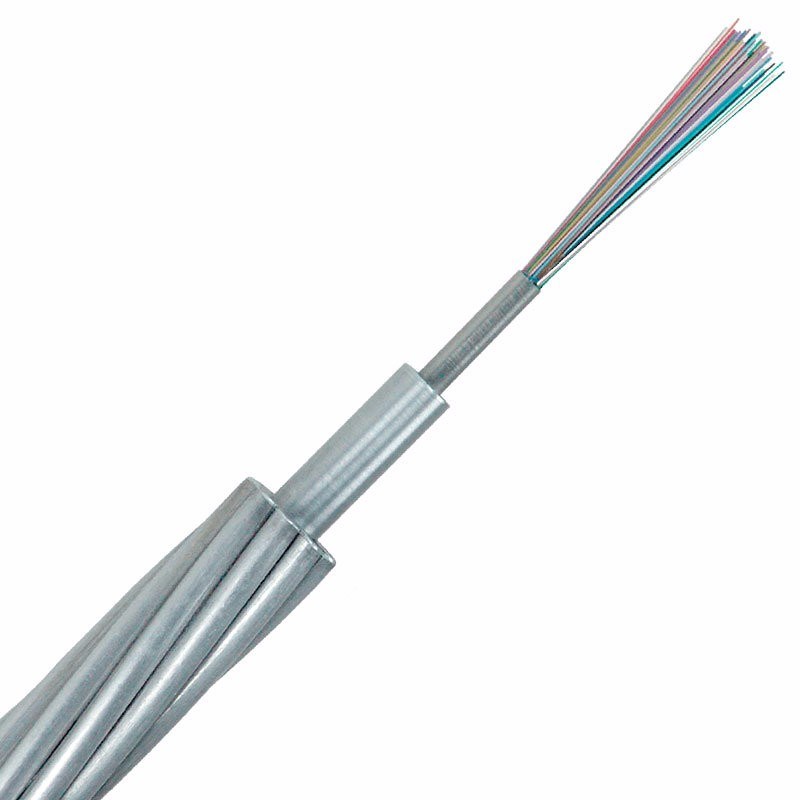

The Cladding Machine for ACS Wire we produce is mainly used to continuously coat aluminum on the surface of steel wire to produce steel core aluminum clad wire (ACS Wire) with good conductivity and corrosion resistance. Cladding Machine for ACS Wire is widely used in power transmission, communication lines and overhead ground wire systems. Through the continuous extrusion process, ACS Wire Extruder can achieve a high-strength combination of aluminum and steel core, ensure uniform coating, stable quality, and greatly improve production efficiency. It is an ideal equipment for mass production of ACS wire. It can produce aluminum-clad steel wire with conductivity of 14-40%.

Specifications of Continuous Cladding Machine for ACS Wire:

| Model | SLB350 | SLB400 |

| extrusion wheel diameter of acs wire extruder (mm) | 350 | 400 |

| Motor power of ACS Wire Extruder (kw) | 200 | 315 |

| Aluminum rod diameter of ACS Wire Extruder (mm) | 2 x 9.5 | 2 x 12 |

| Wire diameter of ACS Wire Extruder (mm) | 3~7 | 3~7 |

| Electrical conductivity of Extrusion Machine for ACS Wire (IACS) | 14~40% | 14~40% |

| Maximum production line speed of Extrusion Machine for ACS Wire (m/min) | 180 | 180 |

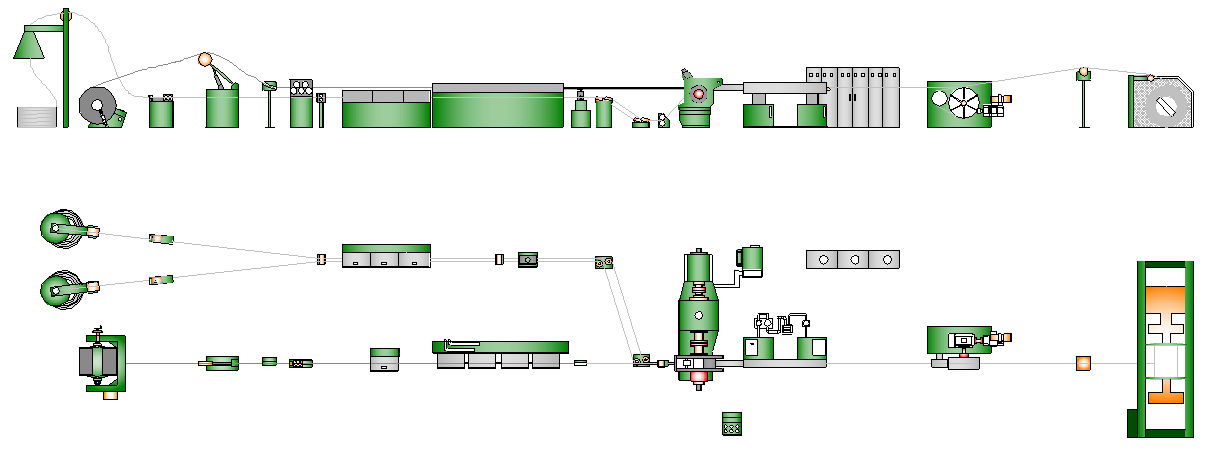

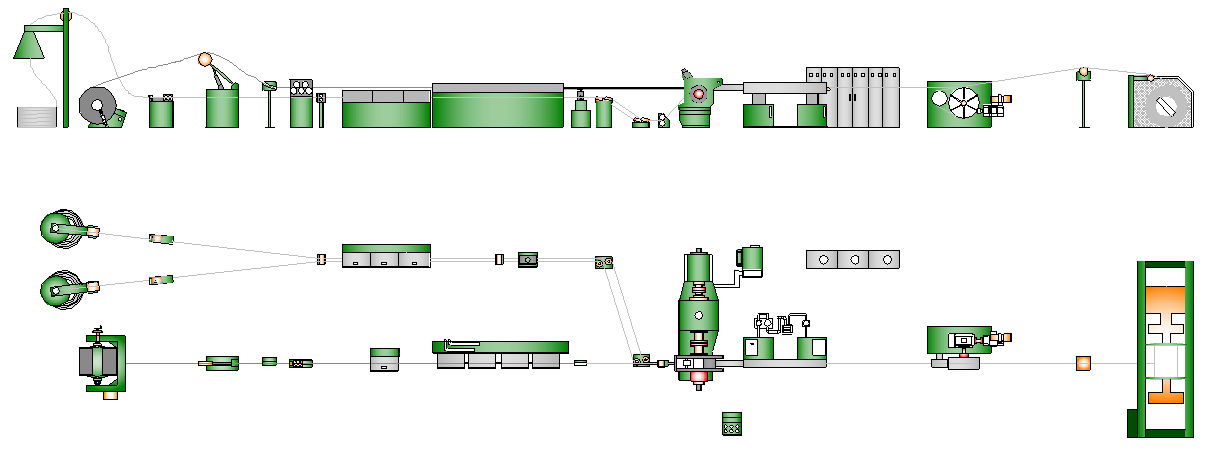

Production line layout of Cladding Machine for ACS Wire:

Dalian Konform Technology Co., Ltd. is the first company in China to successfully develop a complete set of equipment for continuous extrusion and coating of copper and aluminum, covering 250, 300, 350, 400, 500, 550, 630 series, a total of 24 specifications, and has more than 30 core patented technologies. The company has passed ISO9001 quality management system certification and EU CE safety certification, and has delivered more than 1,500 production lines to domestic and foreign customers.

The products are widely used in various ACS Wire Extruder, Cladding Machine for ACS Wire, and Extrusion Machine for ACS Wire projects. The service network covers 29 provinces, municipalities, and autonomous regions in China, and is exported to 52 countries and regions in Asia, Europe, America, Australia, and Africa, winning wide recognition in the international market.

Konform Manufacturing

We take utmost care while manufacturing our products. We have the latest manufacturing machinery from world-renowned names. We procure raw materials and components from the best available sources at home and abroad which must qualify our stringent in-house quality standards. We operate a quality management system accredited to ISO 9001:2008. Our entire production process is carried out in-house and quality checks are conducted at each stage of production.

Dalian Konform Milestone

Year of 2004 | Dalian Konform developed LLJ300A continuous extrusion machine for Microchannel aluminum tube first in China |

Year of 2005 | Dalian Konform developed TLJ400 continuous extrusion machine for copper/aluminum busbar first in China |

Year of 2008 | Dalian Konform developed TLJ630 continuous extrusion machine for copper strip first in China |

Year of 2009 | Dalian Konform developed TLJ500 continuous extrusion machine for copper busbar first in China |

Year of 2010 | Dalian Konform developed LLJ300B continuous extrusion machine for aluminum tube first in China |

Year of 2015 | Dalian Konform developed continuous casting and extrusion machine for aluminum first in China |

Year of 2016 | Dalian Konform developed SSLB500 continuous sheathing machine for high voltage cable sheath in the world |

Year of 2018 | Dalian Konform developed U type continuous extrusion machine for copper strip first in China |

Year of 2019 | Dalian Konform developed 300H high speed continuous extrusion machine for copper&aluminum in the world |

Year of 2022 | Dalian Konform developed TLJ800U continuous extrusion machine for copper strip first in the world |