Introduction of Sheathing Line for Aluminium Sheathed Composite Core:

The Sheathing Line for Aluminium Sheathed Composite Core is designed for high-efficiency metal cladding of electrical cables, ensuring uniform coverage and strong bonding between the metal layer and the cable core. Sheathing line for aluminium sheathed composite core is suitable for processing materials such as aluminum or copper cladding onto steel or other core wires. This continuous cladding machine operates with precision control over tension, alignment, and cladding thickness, making it ideal for applications in power transmission, communication, and specialty cable manufacturing. The continuous process design of continuous cladding machine greatly improves production speed, consistency, and material utilization, while reducing downtime and operational costs.

Applications of High Voltage Power Cable Continuous Coating Machine:

The high voltage cable continuous coating machine we produce is widely used in the manufacturing process of high-voltage transmission cables, mainly used for continuous and uniform insulation coating and protective coating of the outer layer of the cable. Continuous cladding machine can ensure consistent coating thickness and smooth surface, effectively improving the voltage resistance, corrosion resistance and mechanical strength of the cable. Continuous cladding machine is widely used in power, communications, rail transportation, wind power and large-scale industrial engineering and other fields, and is an indispensable and important equipment for high-quality cable production.

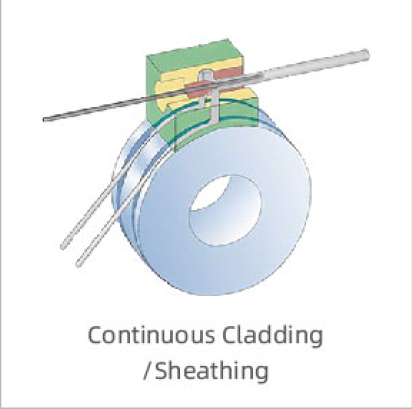

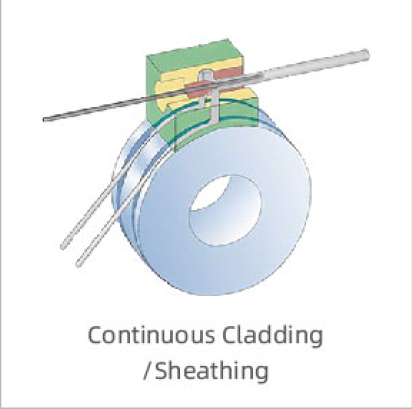

The Principle of Continuous Cladding/ Sheathing is similar to that of continuous extrusion. Using tangential tooling arrangement, the extrusion wheel drives two rods into the cladding/sheathing chamber. Under the high temperature and pressure, the material either reaches the condition for metallurgical bonding and forms a metal protective layer to directly clad the metal wire core that enters the chamber,or is extruded through the space between mandrel and cavity die to form a metal sheath without contacting the wire core. Double-wheel cladding/sheathing uses two extrusion wheels, to provide four rods to clad/sheath large diameter wire core.

Specifications of High Voltage Power Cable Continuous Coating Machine:

| Model | SLB350 | SLB400 |

| Extrusion wheel diameter (mm) | 350 | 400 |

| Motor power (kW) | 160 | 250 |

| Aluminum rod diameter (mm) | 2×9.5 | 2×9.5/2×12 |

| Wire diameter (mm) | 4~28 | 8~46 |

| Thickness of sheath (mm) | 0.6~3 | 0.6~3 |

| Outer diameter of sheath (mm) | 6~30 | 20~50 |

| Maximum production line speed (m/min) | 60 | 60 |

1. What types of cables are suitable for Continuous cladding machine?

Sheathing Line for Aluminium Sheathed Composite Core is suitable for a variety of power cables, communication cables and special industrial cables, especially for high-performance cable products that require metal coating.

2. What are the options for coating materials?

Sheathing Line for Aluminium Sheathed Composite Core supports a variety of metal materials such as aluminum, copper, and steel as coating layers, which can be flexibly configured according to customer process requirements.

3. Will the coating process affect the performance of the cable?

No. High Voltage Power Cable Continuous Coating Machine uses a precision control system to ensure uniform coating and good adhesion, without affecting the conductivity and structural integrity of the cable.

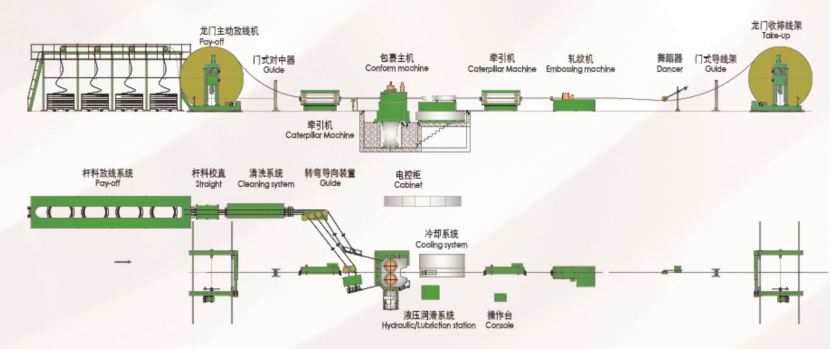

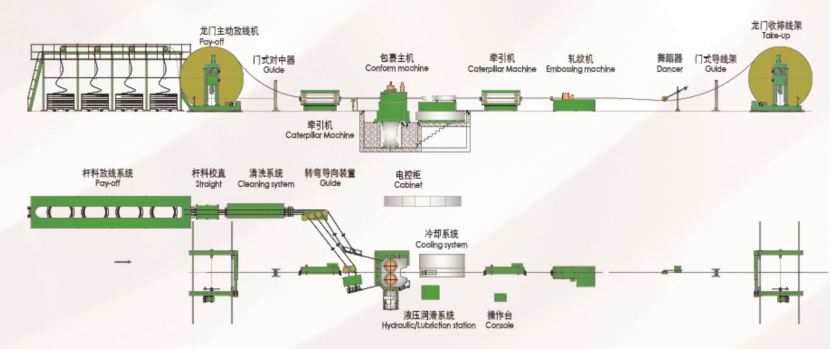

Production line layout of Continuous cladding machine:

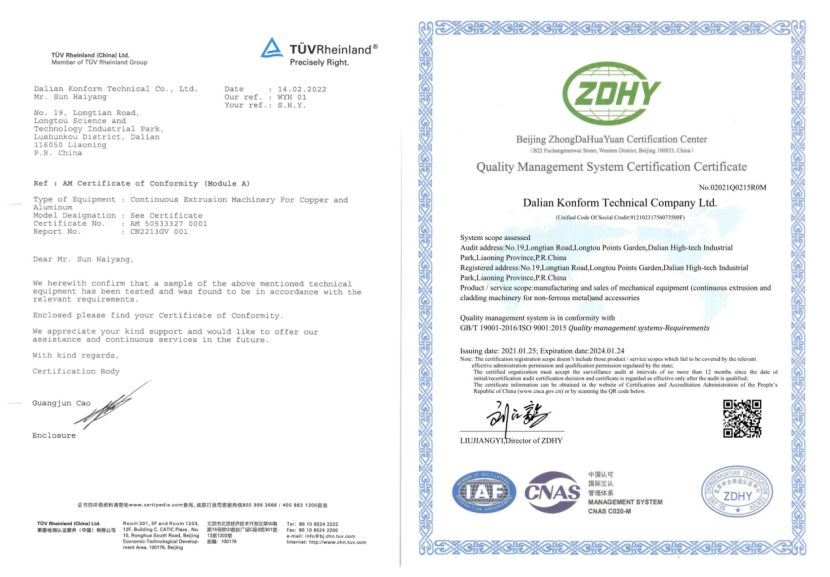

Our certificate of Continuous cladding machine:

Konform Service

We pay great attention to customer needs. Equipped with our entire production line ranging from model 250-800, our lab can carry out production test for new products and new material required by our customers. Through effective presale collaboration, we provide valuable technical advice and recommendations to and develop close working relationships with customers, so that they can confidently place an order.

We have a strong after-sales service team (about 30 mechanical and electrical engineers) with rich professional knowledge and practical experience to provide commissioning, maintenance, and repair service to our customers all over the world. They can reach to customer's plant at very short time, If they need, we can provide online support or remote control for 24 hours.

Our advantages of high voltage cable continuous coating machine

Advanced processing methods and strict processing technology ensure the excellent quality and durable life of Konform equipment. The high voltage cable continuous coating machine is fully debugged before leaving the factory, and there is absolutely no flaw in the customer.

We have established a strict supply chain management system of high voltage cable continuous coating machine: raw materials and supporting components are provided by well-known domestic and foreign companies, and electrical components are all made of first-class brands at home and abroad.