Product introduction of Railway Signal & Communication Cable:

The CATV cable aluminum sheathed wire we produce is specially designed for signal transmission and communication needs in railway systems, with excellent anti-interference performance, weather resistance and long-term stability. CATV cable aluminum sheathed wire is widely used in key systems such as railway signal control, train dispatching communication, track circuits, etc. to ensure the accuracy of signal transmission and the reliability of system operation. The CATV cable aluminum sheathed wire we produce usually has the characteristics of flame retardancy, high temperature resistance, high tensile strength, etc., suitable for complex and changeable railway operation environment, and is an important communication carrier to ensure the safe operation of railways.

Principle of Railway Signal & Communication Cable:

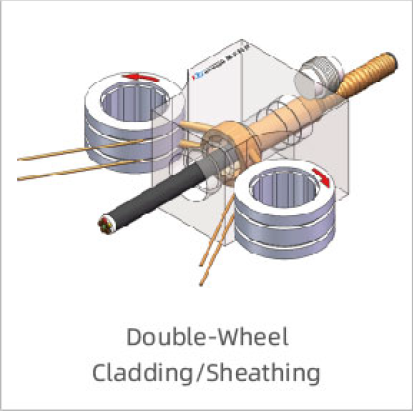

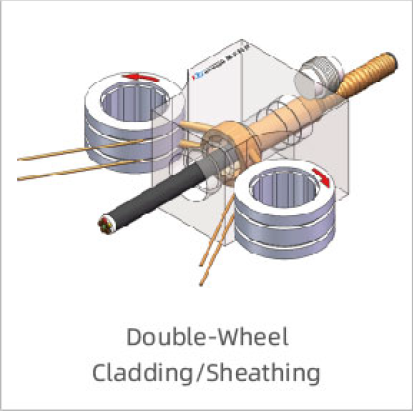

The principle of Railway Signal & Communication Cable is similar to the continuous extrusion process. Railway Signal & Communication Cable uses a tangential tooling arrangement, and the extrusion wheel drives two rods into the sheathing/ jacketing cavity. Under the action of high temperature and pressure, the material either reaches a metallurgical bonding state to form a metal protective layer, which directly covers the metal wire core entering the cavity; or it is extruded through the space between the core mold and the cavity, without contacting the wire core to form a metal sheath. The Railway Signal & Communication Cable process uses two extrusion wheels to provide four rods for sheathing/jacketing large diameter wire cores.

Use of Continuous Cladding Machine for CATV Cable:

Aluminum Sheathing Machine for CATV Cable is mainly used to continuously and evenly coat the outside of coaxial cables with metal or polymer materials to form an effective shielding layer and protective layer. Aluminum Sheathing Machine for CATV Cable can improve the cable's ability to resist electromagnetic interference (EMI), enhance mechanical strength, and ensure the stability and high quality of signal transmission. In the fields of cable television, broadband networks, and data transmission systems, Aluminum Sheathing Machine for CATV Cable is an important equipment for manufacturing high-performance CATV cables. Aluminum Sheathing Machine for CATV Cable can produce aluminum-clad steel wire with conductivity of 14-40%.

Specifications of Continuous Cladding Machine for Cable:

| Model | SSLB 500 |

| Extrusion wheel diameter of Continuous Cladding Machine for Cable (mm) | 2*500 |

| Motor power of Continuous Cladding Machine for Cable (kw) | 600 |

| Aluminum rod diameter of Continuous Cladding Machine for Cable (mm) | 4 x 15 |

| Wire diameter of CATV cable aluminum sheathed wire (mm) | 50~160 |

| Sheath Thickness of CATV cable aluminum sheathed wire | 2~4 |

| Maximum production line speed (m/min) | 180 |

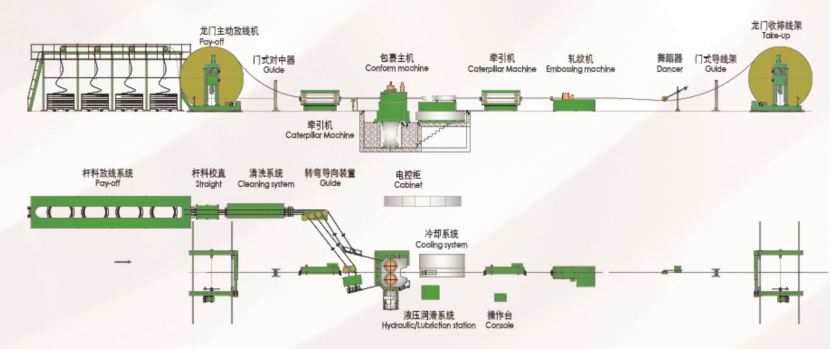

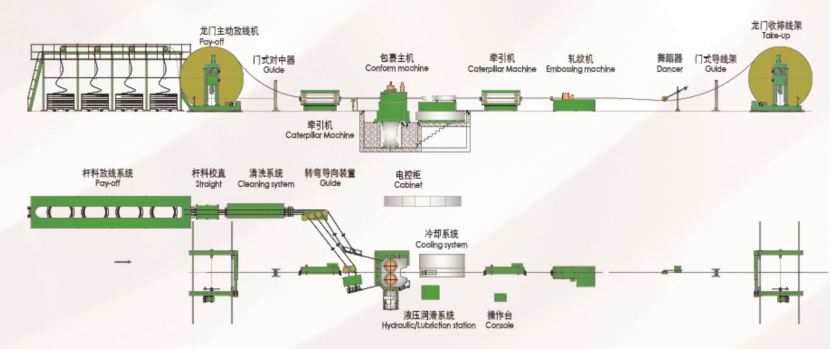

Production line layout of Continuous Cladding Machine for ACS Wire:

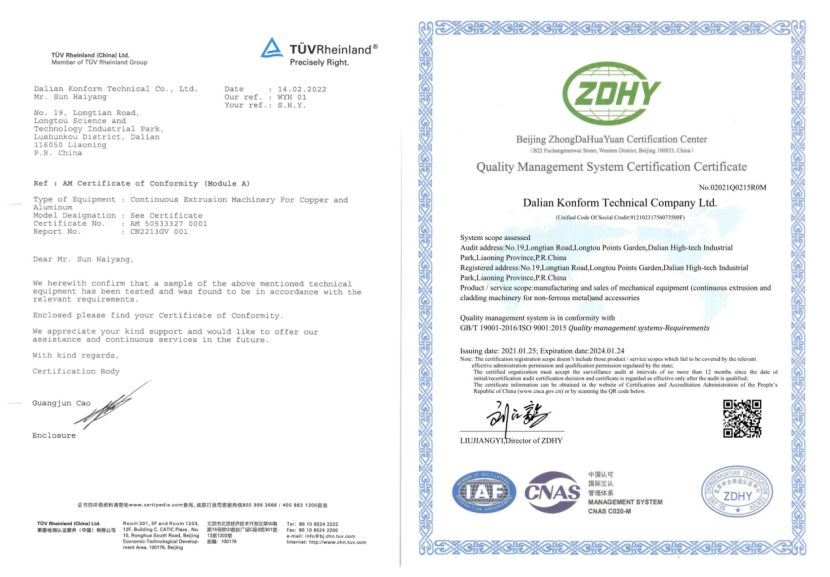

Our certificate of Continuous Cladding Machine for ACS Wire:

Konform Service:

Customer service is often the first interaction customers have with us—and the impression it leaves can be lasting. It plays a crucial role in building trust and long-term partnerships. We place strong emphasis on understanding and responding to customer needs. Our in-house laboratory, equipped with a full range of Continuous Cladding Machines for Cable and Continuous Cladding Machines for ACS Wire (models 250 to 800), allows us to conduct thorough production tests using new materials or for new product development based on customer requirements. By working closely with clients during the presale phase, we offer tailored technical guidance and support, helping them make informed decisions and move forward with confidence when placing orders.

We have a dedicated after-sales service team of around 30 experienced mechanical and electrical engineers, equipped with solid technical expertise and hands-on experience. They are capable of providing timely support for equipment commissioning, maintenance, and repair worldwide. When needed, our engineers can quickly travel to the customer's site, and we also offer 24/7 online assistance or remote troubleshooting to ensure smooth operation.

Our Advantage of Continuous Cladding Machine for ACS Wire:

As a world leader in the continuous extrusion industry—accounting for 50% of global sales—we offer advanced Continuous Cladding Machines for Cable and Continuous Cladding Machine for ACS Wire that set the benchmark for performance and efficiency. Our latest models feature comprehensive data monitoring and 24/7 remote maintenance support, achieving 20% energy savings per ton, 80% higher output, and 60% less space usage compared to traditional equipment. Engineered for high precision and long service life, the machines require only one operator for full control. Backed by a dedicated R&D team and an independent testing lab, we continuously improve our technology based on customer-specific materials. All critical components come from world-renowned brands such as Siemens and ABB, with top-tier domestic gearboxes and couplings ensuring reliability. Our after-sales team of 30 experienced engineers provides global on-site service and rapid response, along with around-the-clock online support to guarantee uninterrupted production.

FAQs:

Q: What types of cables are suitable for Continuous Cladding Machine for ACS Wire?

A: Continuous Cladding Machine for ACS Wire is mainly suitable for continuous metal or polymer coating of various communication cables, coaxial cables, power cables, etc., to ensure that the cables have good shielding, mechanical strength and environmental tolerance.

Q: What is the production capacity of Continuous Cladding Machine for Cable?

A: The production capacity of Continuous Cladding Machine for Cable depends on the selected model and material. Generally, the output range is 200 to 800 kg per hour. Some new equipment can increase the output by more than 80%.

Q: Can CATV cable aluminum sheathed wire adapt to the coating needs of different materials?

A: Yes. Our laboratory can test the new materials provided by customers, and the CATV cable aluminum sheathed wire supports the coating process of multiple material types (such as aluminum, copper, and composite materials).

Q: Do you provide after-sales technical support of Railway Signal & Communication Cable?

A: We provide global after-sales service of Aluminum Sheathing Machine for CATV Cable. We have more than 30 experienced engineers to support on-site installation and commissioning, maintenance services, and provide 7x24 hours online remote technical support.