What is Copper Flat Wire Conform Machine?

Copper Flat Wire Conform Machine is a device specially used to process copper rods into flat copper wires. Metal Wire Conform Machine can work continuously to make copper materials into the required flat wire shape, with fast speed, good forming, saving time and cost. This Metal Wire Conform Machine is easy to operate and suitable for the production of electrical equipment, busbars, electronic accessories and other products, which can help many copper processing companies improve efficiency.

Specifications of Metal Wire Conform Machine:

| Model | TLJ300 | TLJ300H |

| Nominal diameter of extrusion wheel(mm) | 300 | 300 |

| Main motor power(kw) | 90 | 110 |

| Copper rod diameter(mm) | 12.5 | 12.5 |

| Maximum width of flat wire products(mm) | 40 | 30 |

| Minimum diameter of round product(mm) | 2.6 | 2.6 |

| Cross-sectional area of flat wire products(mm2) | 5~200 | 5~150 |

| Efficiency(kg/h) | 480 | 900 |

Why choose our Copper Flat Wire Conform Machine?

The Metal Wire Conform Machine we produce has high efficiency, strong stability, and good forming effect, which can meet the production needs of copper flat wires of different sizes and shapes. Copper Flat Wire Conform Machine has a reasonable structure and is easy to operate, suitable for long-term continuous operation, which improves customers' production capacity and product consistency. Our factory has a complete production system and rich manufacturing experience. Each Metal Wire Conform Machine undergoes strict quality inspection and debugging to ensure stable operation when it leaves the factory. At the same time, we also provide customized services and technical support to help customers quickly put into production, save worry and be efficient.

Conform Machine for Copper Flat Wire quality inspection:

In our factory, product quality inspection is an important part of the production process. Each Copper Flat Wire Conform Machine will undergo a number of rigorous tests before leaving the factory, including component size inspection, assembly accuracy test, operation stability test, etc., to ensure that every detail meets the standard. We are equipped with a professional quality inspection team and advanced testing equipment to ensure that every level of inspection is carried out without missing any details. At the same time, during the Copper Flat Wire Conform Machine debugging process, we will also simulate the actual use scenario of the customer for testing to ensure that Metal Wire Conform Machine can be put into production smoothly and run stably after arriving at the customer's site.

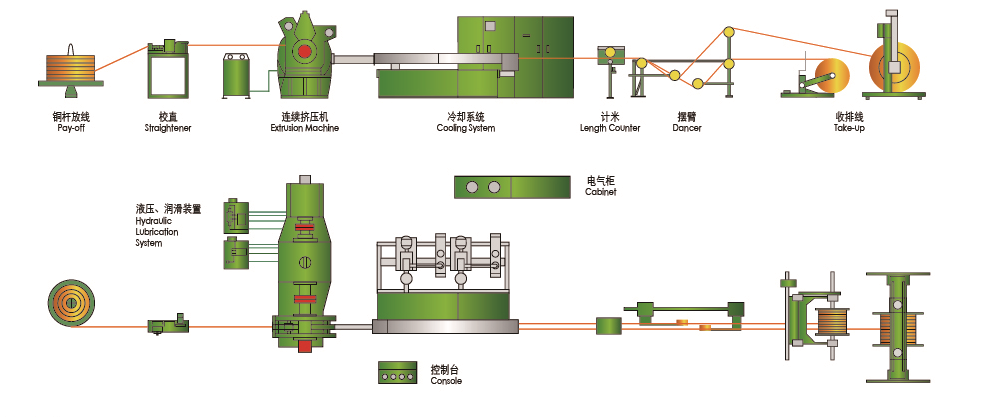

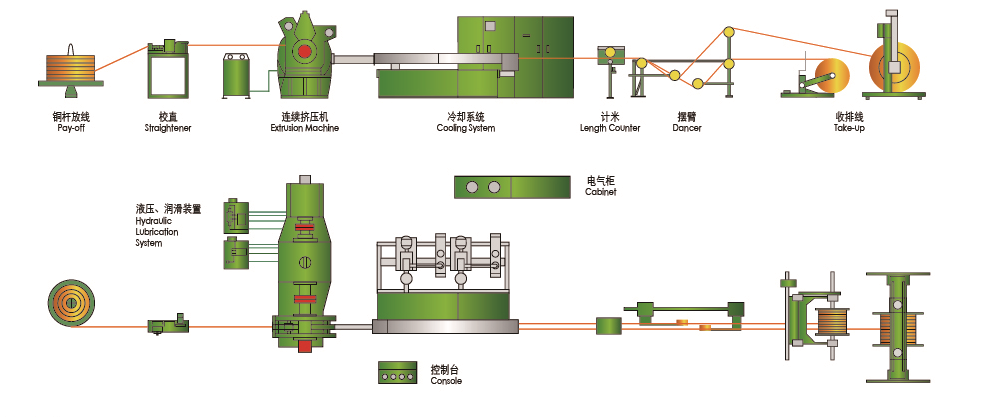

Production line layout:

About us:

Originally established in 1993, Dalian Konform Technical Company, Ltd. is a world-leading provider of the continuous extrusion technology and equipment. Our research and development history in this area dated back to 1984. In over thirty years, we have provided highly efficient solutions for continuous extrusion, continuous cladding and continuous sheathing to our clients in the field of non-ferrous metal processing and cable manufacturing. Our equipment is widely recognized for its reliability and quality. All of our machines meet EU CE requirements and are manufactured under the ISO 9001 quality management system.