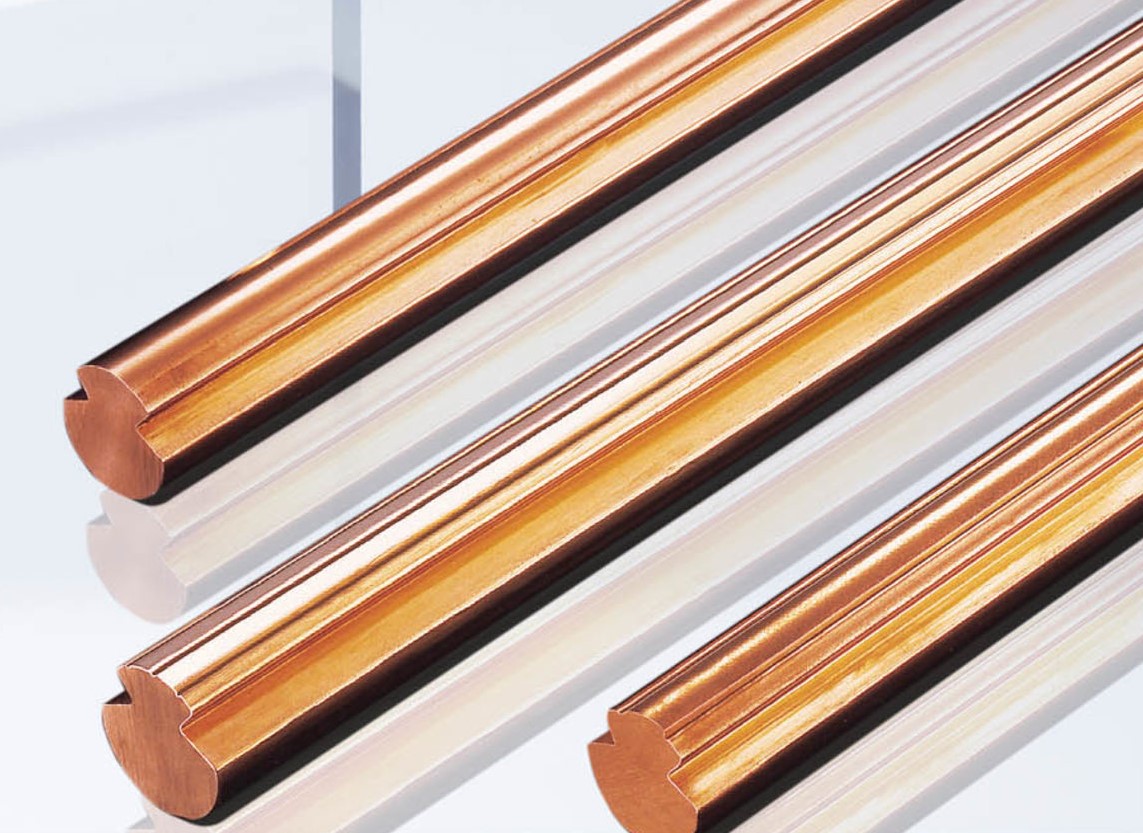

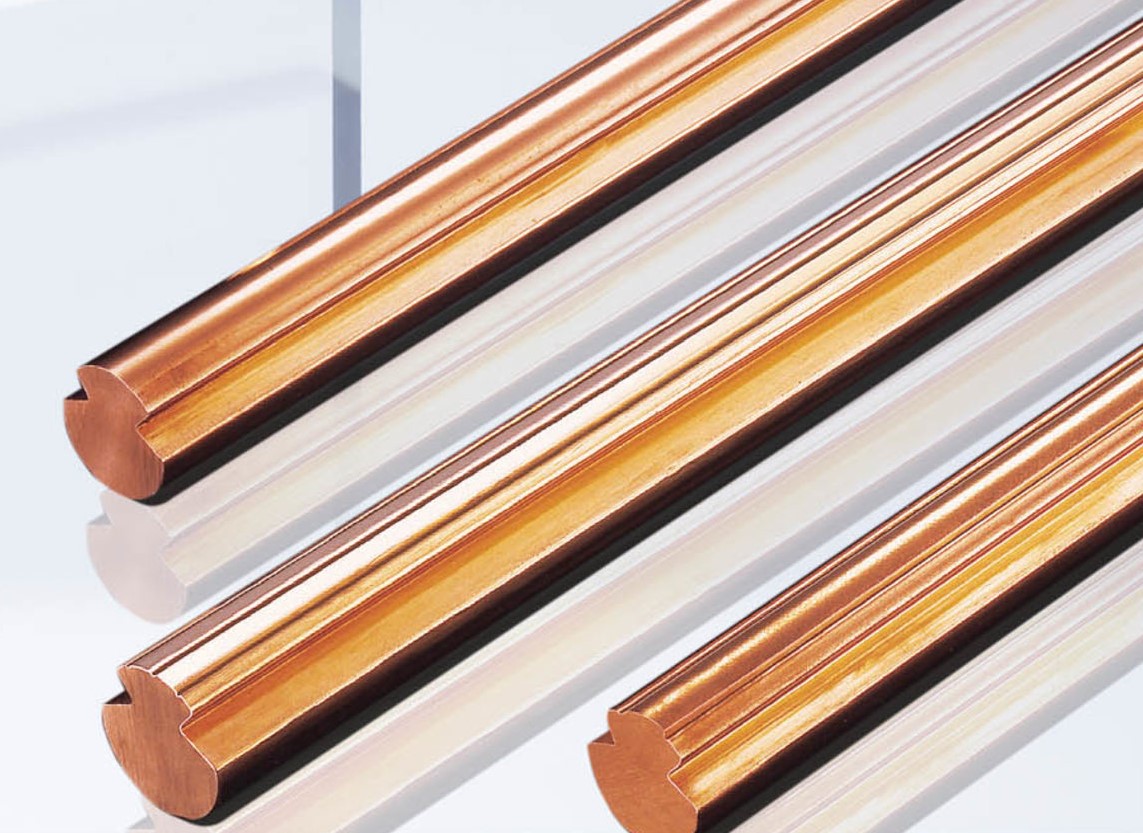

Product Introduction of Copper or Aluminum Conform Machine:

Copper or Aluminum Conform Machine is designed to extrude a variety of metals, including copper and aluminum, through a continuous process. The process involves heating the metal billet to a specified temperature and then pressing it into a die to form a long, uniform profile. Conform Machine for Metal is equipped with a PLC-based control unit that monitors temperature, pressure and output, ensuring precise and reliable operation. Features such as Conform Machine for Metal's induction coil heater, powerful hydraulic system and enhanced safety controls help improve the machine's efficiency and ability to handle large-scale industrial operations.

Product Application of Copper Wire Conform Machine:

Copper Wire Conform Machine is widely used in industries that require continuous, precise metal profiles. Copper Wire Conform Machine is often used to produce electrical conductors, automotive parts, aerospace components, and structural parts. Conform Machine for Metal's ability to consistently produce high-quality extruded profiles is essential for industries that require strong, lightweight, and durable metal products.

Specifications of Copper Wire Conform Machine:

| Model | TLJ350 | TLJ350H | TLJ400 |

| Nominal diameter of extrusion wheel (mm) | 350 | 350 | 400 |

| Main motor power (kW) | 160 | 200 | 250 |

| Diameter of copper rod (mm) | 16 | 16 | 20 |

| Maximum width of product (mm) | 100 | 100 | 170 |

| Diameter of round rod product (mm) | 4.5~50 | 4.5~50 | 8~90 |

| Product cross-sectional area (mm2) | 15~1000 | 15~1000 | 75~2000 |

| Productivity (kg/h) | 780 | 950 | 1200 |

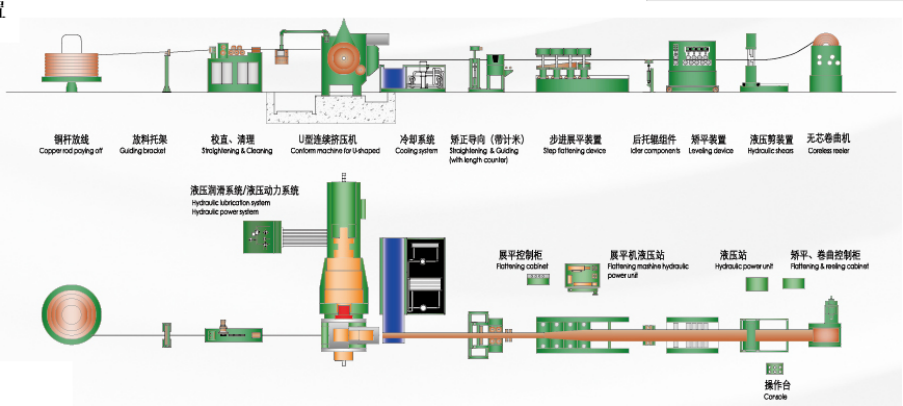

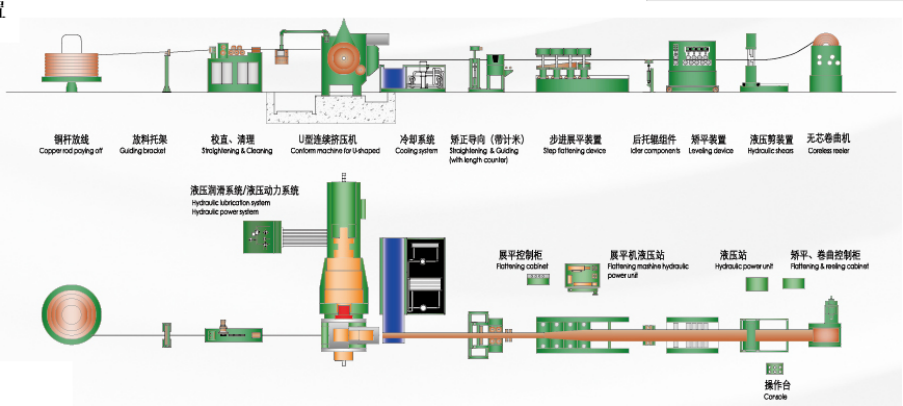

How Conform Machine for Metal works:

The copper rod (usually 8mm or larger diameter) is fed into the Copper or Aluminum Conform Machine automatically or manually.

The copper rod is heated by an induction heater to improve plasticity and reduce extrusion resistance.

The copper rod is fed between the rotating extrusion wheel and the forming die by a servo motor or a traction system.

Using the friction drive principle, the copper rod is extruded between the extrusion wheel and the die at high pressure to form the required cross-sectional shape (such as flat wire, rectangular wire, etc.).

The newly formed copper wire is quickly cooled and shaped by a water cooling or air cooling system.

The finished copper wire is pulled out by the traction system and reeled or cut at the required speed.

The copper wire size, surface quality and continuity are detected online.

About us:

Originally established in 1993, Dalian Konform Technical Company, Ltd. is a world-leading provider of the continuous extrusion technology and equipment. Our research and development history in this area dated back to 1984. In over thirty years, we have provided highly efficient solutions for continuous extrusion, continuous cladding and continuous sheathing to our clients in the field of non-ferrous metal processing and cable manufacturing.

Building on over thirty patented technical innovations, Dalian Konform have developed twenty-four different models under three product categories (continuous extrusion, continuous cladding and continuous sheathing for copper and aluminum). We are certified to ISO 9001 standard and our products comply with EU CE marking. As of 2020, we have designed and manufactured more than 1500 production lines for our clients in 52 countries covering all six continents. They are widely used to produce AS wire, OPGW, aluminum sheathing of power cable, copper flat wire, copper bus bar, copper strip blank, aluminum tube, aluminum conductor etc.