Product introduction of copper wire continuous rotary extrusion line:

Our range of copper wire continuous rotary extrusion line is an efficient copper wire production line. It can be applied to extrude different types of copper wires, including copper flat wires, round wires, and profile wires. These copper products are commonly used in the forming of transformer, large and medium sized motor, high and low voltage switch electric appliance, DC motor commutator, etc.

Specifications of Continuous Rotary Extrusion Machine for Copper Wire:

| Model | TLJ300 | TLJ300H | TLJ350H |

| Nominal diameter of extrusion wheel(mm) | 300 | 300 | 350 |

| Main motor power(kw) | 90 | 110 | 160 |

| Copper rod diameter(mm) | 12.5 | 12.5 | 16 |

| Maximum width of flat wire products(mm) | 40 | 30 | 100 |

| Minimum diameter of round product(mm) | 2.6 | 2.6 |

|

| Cross-sectional area of flat wire products(mm2) | 5~200 | 5~150 | 4.5~50 |

| Efficiency(kg/h) | 480 | 900 | 780 |

What products can Copper Wire Extrusion Machine produce:

Copper flat wire: used in motors, transformers, electrical connections and other industries.

Copper busbars/busbars: widely used in power distribution equipment, switch cabinets, and power systems.

Copper strips: used for cable sheathing, electronic components, heat sinks, etc.

Copper round wire: can be used for re-drawing, producing enameled wire or communication wire.

Working Process of Rotary Extrusion Machine for Copper Wire:

This Rotary Extrusion Machine for Copper Wire uses the oxygen-free pure copper rod which is manufactured using upward casting technique as the feed stock. The feed stock is firstly unwound by the payoff machine, and then is conveyed to the continuous extrusion machine after straightening. After extruded into wire stocks, the semi-finished products are specially treated to help prevent oxidation, before they are delivered to the cooling system. With the help of the take-up machine, the extruded copper wires are rewound.

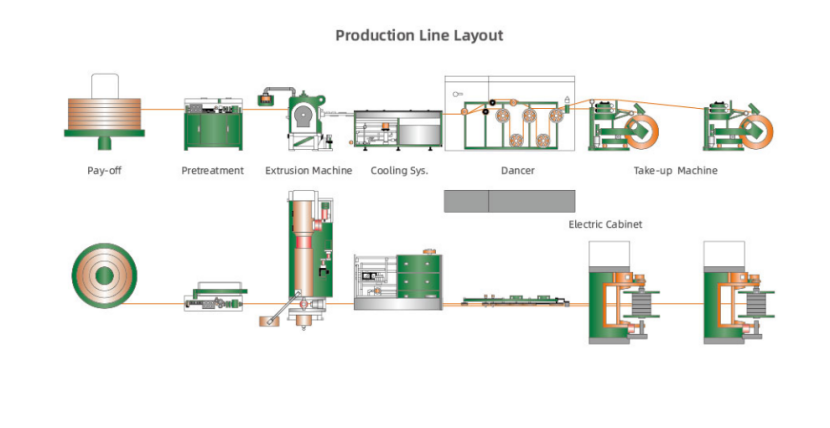

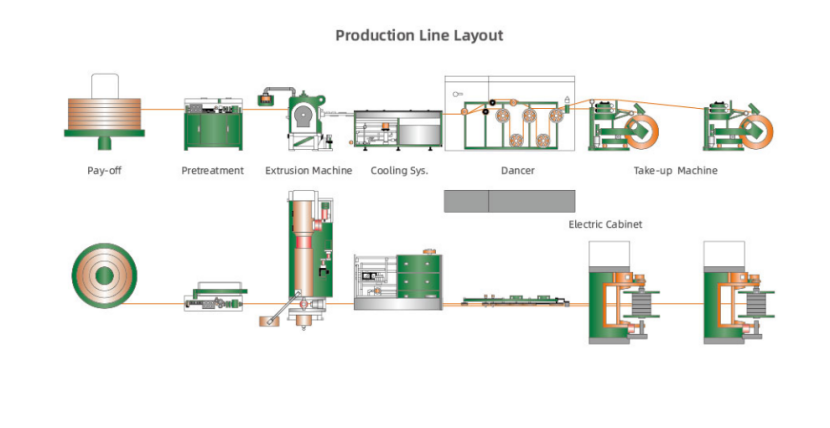

Production line layout of copper wire continuous rotary extrusion line:

About us:

Founded in 1993, Dalian Konform Technical Company, Ltd. is a global leader in continuous extrusion technology and equipment. Our expertise in this field traces back to 1984, and over the past three decades, we have delivered efficient continuous extrusion, cladding, and sheathing solutions to customers in the non-ferrous metal processing and cable manufacturing industries.

With more than 30 patented innovations, we have developed 24 machine models across three major product lines—covering continuous extrusion, cladding, and sheathing applications for both copper and aluminum. Our operations are ISO 9001 certified, and our products meet EU CE standards. By 2020, we had designed and built over 1,500 production lines, serving clients in 52 countries across all continents. These machines are widely used for manufacturing products such as AS wire, OPGW, aluminum cable sheathing, copper flat wire, bus bars, copper strip blanks, aluminum tubes, and conductors.