What is Extrusion Machinery for Copper Bar?

Extrusion Machinery for Copper Bar is a machine used to process copper rods into copper wires of various shapes, such as round wires, flat wires, special-shaped wires, etc. Extrusion Machinery for Copper Bar presses copper materials into the required shape through continuous extrusion, with high speed and efficiency, and does not require complicated processing. Extrusion Machine Process is easy to operate and suitable for use in industries such as wires and cables, electronic components, and hardware accessories. It can greatly save labor and materials and is a practical equipment commonly used in many copper processing plants.

Specifications of Copper Pipe Extrusion Process:

Model | TLJ350 | TLJ400 | TLJ500 | TLJ630 |

Nominal diameter of extrusion wheel (mm) | 350 | 400 | 500 | 630 |

Main motor power (kw) | 160 | 250 | 355 | 600 |

Copper rod diameter (mm) | 16 | 20 | 25 | 30 |

Product maximum width (mm) | 100 | 170 | 260 | 320 |

Round bar product diameter (mm) | 4.5~50 | 8~90 | 12~100 | 12~100 |

Product cross-sectional area (mm²) | 15~1000 | 75~2000 | 300~3200 | 600~6400 |

Productivity (kg/h) | 780 | 1200 | 1800 | 2800 |

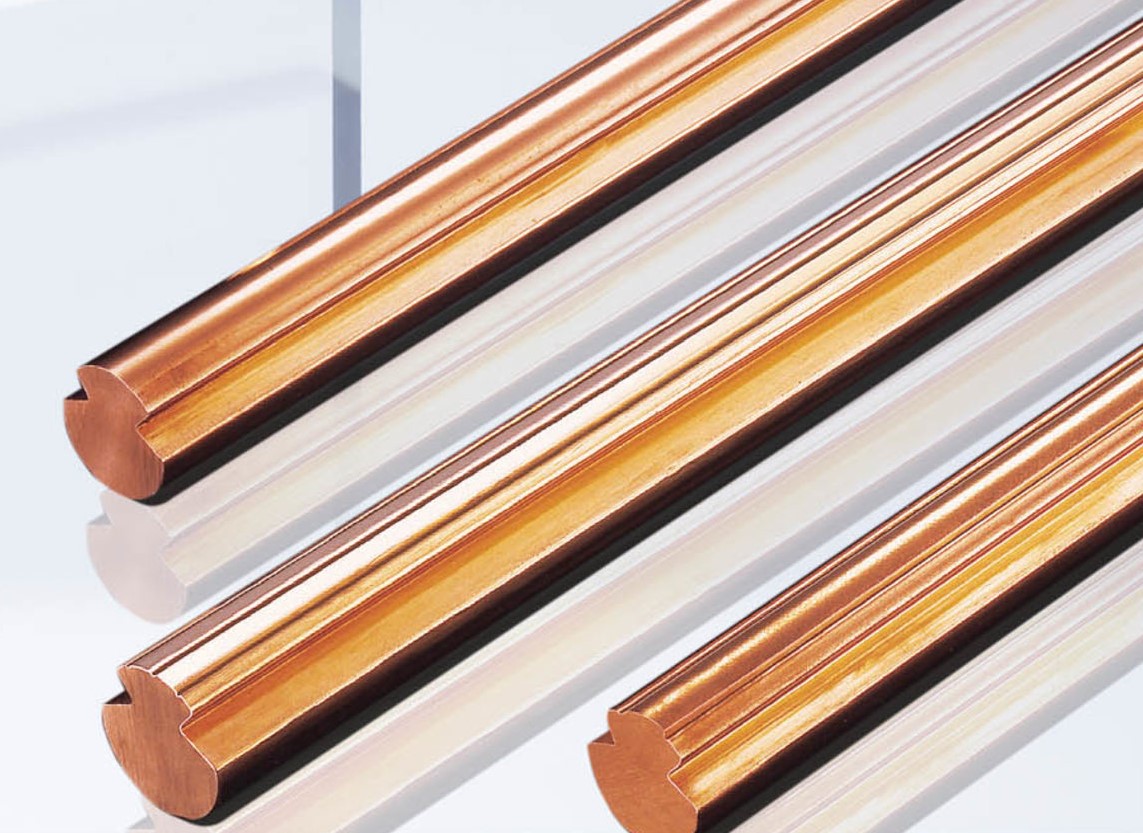

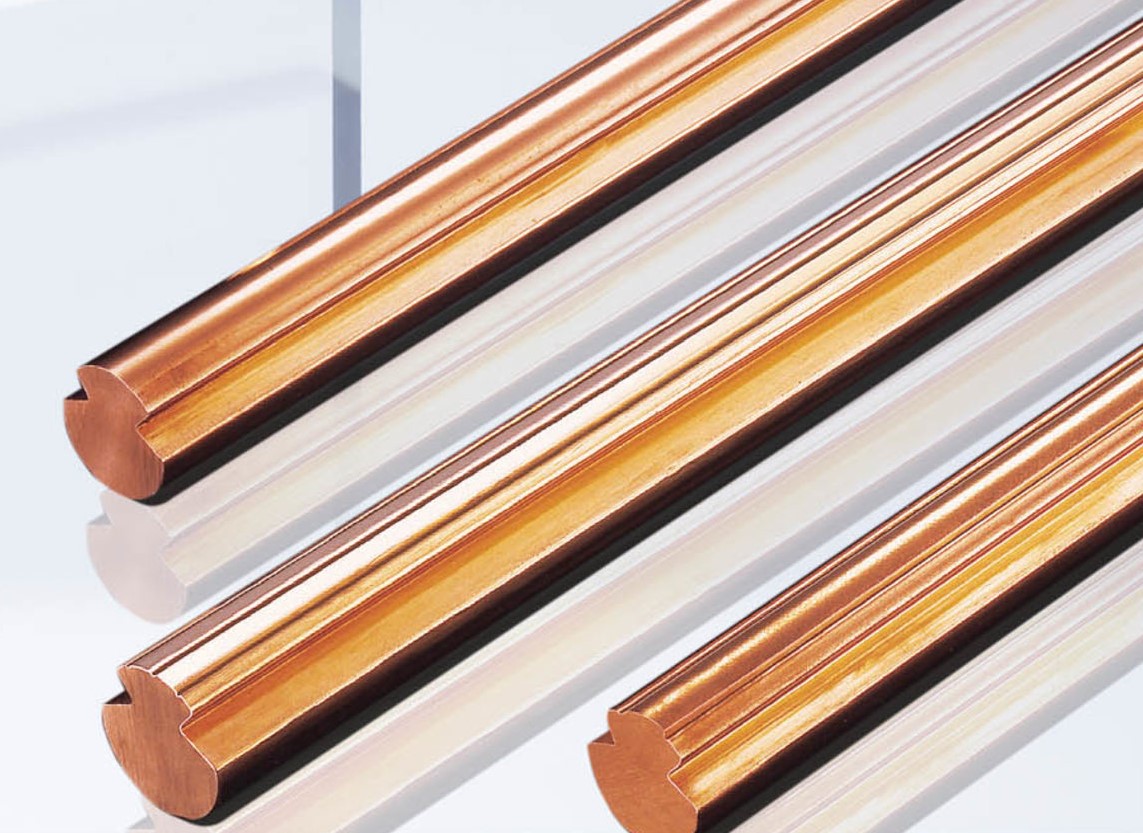

What does Copper Pipe Extrusion Process look like?

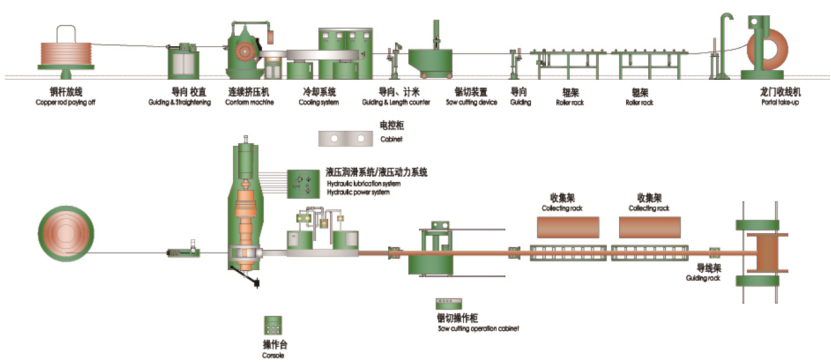

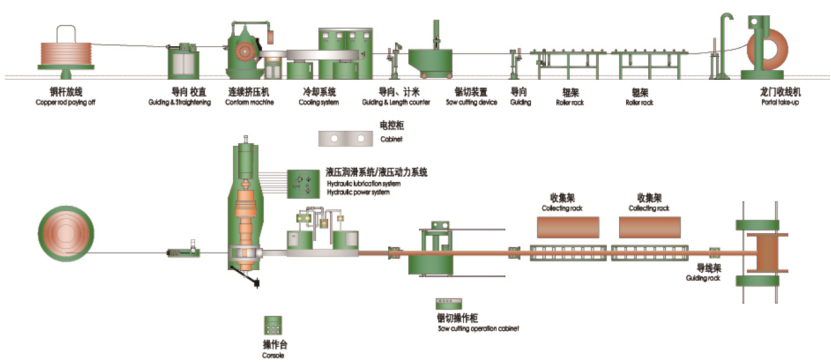

Extrusion Machinery for Copper production line layout:

Our advantages: advanced manufacturing, scientific management

Building on over thirty patented technical innovations, Dalian Konform have developed twenty-four different models under three product categories (continuous extrusion, continuous cladding and continuous sheathing for copper and aluminum). We are certified to ISO 9001 standard and our products comply with EU CE marking. As of 2023, we have designed and manufactured more than 1800 production lines for our clients in 53 countries covering all six continents. They are widely used to produce AS wire, OPGW, aluminum sheathing of power cable, copper flat wire, copper bus bar, copper strip blank, aluminum tube, aluminum conductor etc.

Efficiently operated Konform factory:

In our factory, workers strictly follow the operating specifications to ensure that each process is safe and orderly. Every employee will receive professional training before taking up the post and be familiar with the Copper Pipe Extrusion Process operating procedures and safety precautions. During the production process, management personnel conduct regular inspections to promptly discover and deal with problems to ensure stable production operations. At the same time, the workshop has clear signs and work area divisions to facilitate efficient collaboration among workers.

About us:

With more than 30 patented technical innovations, Dalian Konform has independently developed 24 different machine models across three product lines: Extrusion Machine Process continuous extrusion, continuous cladding, and continuous sheathing for copper and aluminum materials.