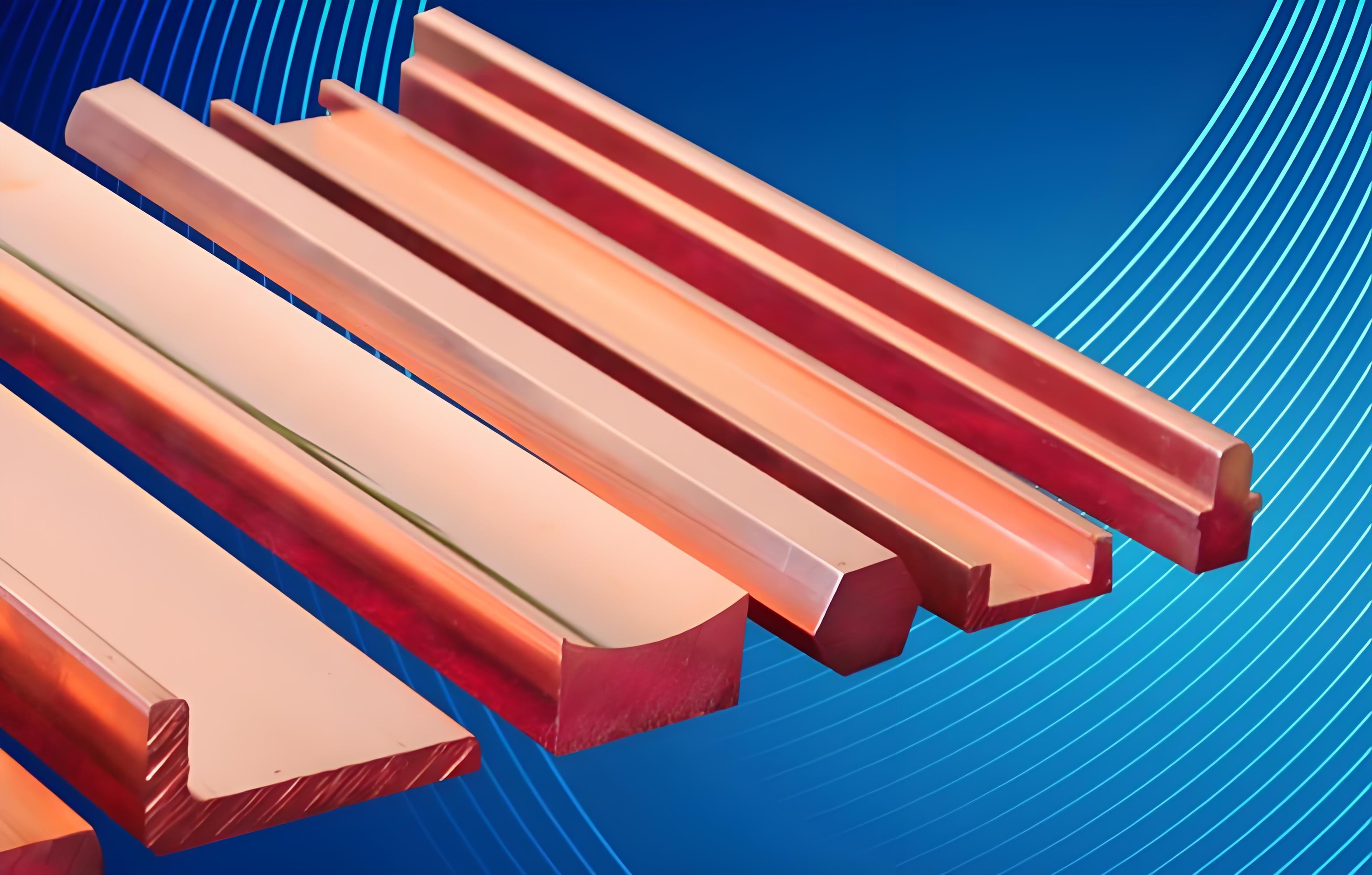

Introduction of High Speed Conform Machine:

High speed conform machine is a kind of equipment used to process copper bars of different specifications. High speed conform machine combines advanced automation control technology and high-precision machining capabilities, which can quickly complete the punching, bending, cutting, crimping and other processes of copper bars to ensure accurate product dimensions. Therefore, copper rod conform machine is widely used in industries such as power, communication, rail transportation, and new energy vehicles.

Purpose of High Speed Conform Machine for Copper:

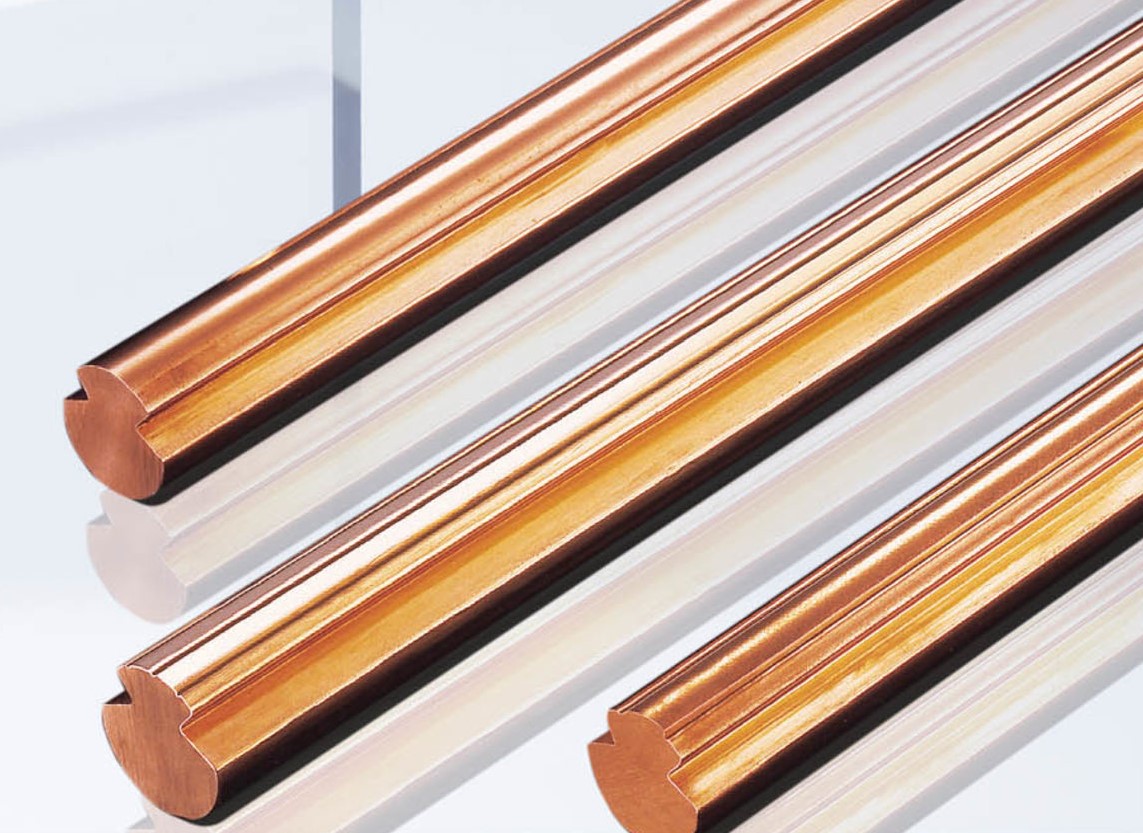

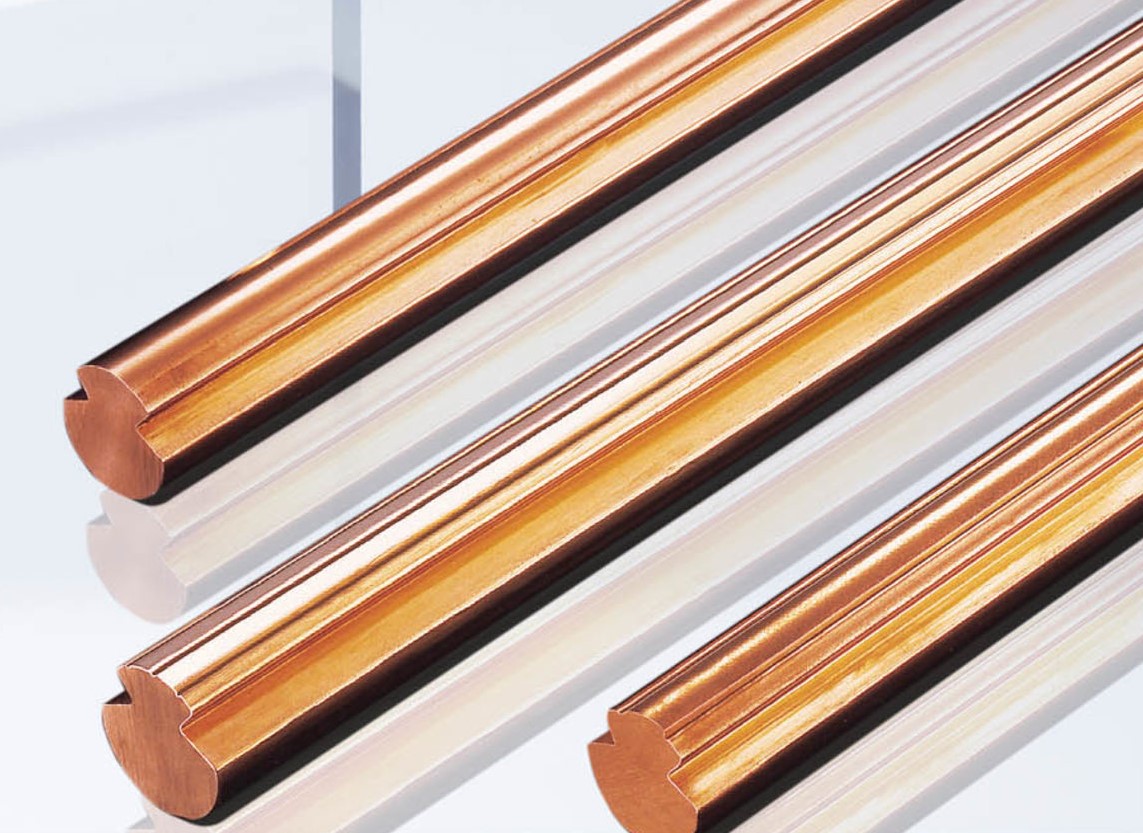

Conform Machine for Copper can produce various specifications of copper bars, copper busbar and copper profiles.Copper extrusion equipment is widely used in the fields of power, new energy, rail transportation, automobile manufacturing, etc. Copper extrusion equipment is used in the power industry to produce copper bars used in substations, distribution cabinets, switchgear, etc. High speed extrusion machine can also produce high-conductivity copper bars required for the battery connection system of new energy vehicles, and continuous extruder meets this production standard. Continuous extruder can meet the mass processing needs of train power supply systems. Continuous extruder can also produce copper bars used in communication equipment, telecommunications base stations and other equipment.

Specifications of High Speed Conform Machine for Copper Busbar&Rod :

| Model | TLJ300H | TLJ350H | TLJ400H |

| Nominal diameter of extrusion wheel (mm) | 300 | 350 | 400 |

| Main motor power (kW) | 110 | 200 | 315 |

| Diameter of copper rod (mm) | 12.5 | 16 | 20 |

| Maximum width of product (mm) | 30 | 100 | 170 |

| Diameter of round rod product (mm) | min 2.6 | 4.5~50 | 8~90 |

| Product cross-sectional area (mm2) | 5~150 | 15~1000 | 75~2000 |

| Productivity (kg/h) | 800 | 950 | 1500 |

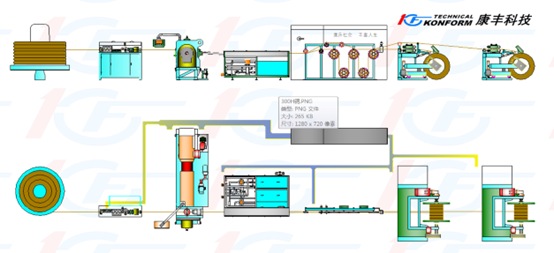

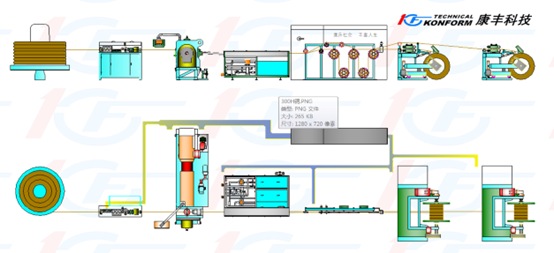

Production line layout

Advantages of Copper Rod Conform Machine Compared withStandard Models:

1. The production capacity of copper rod conform machine is 2-3 times higher than that of traditional models.

2. Copper rod conform machine can save more than 20% of energy

3. Copper rod conform machine can also save operators: One or two people operate 4-5 lines.

4. Copper rod conform machine can save 60% of space.

5. Copper extrusion equipment can increase the life of the extrusion wheel and improve product quality.

6. The surface of copper extrusion equipment is free of bubbles and has good quality.

7. Copper extrusion equipment has good wiring, no scratches, and no paper pad is required for winding.

8. Copper extrusion equipment is not only safe and reliable, but also has a low failure rate.

9. High speed extrusion machine can lay the foundation for smart factories and monitor operating status and production data in real time.

10. High speed extrusion machine can provide remote troubleshooting services.

11.High speed extrusion machine has a noise level less than 82db, no oil or water leakage, and is very environmentally friendly.

TLJ 400H High Speed Extrusion Machine Feature:

1. High Speed Conform Machine has a unique cooling system and intelligent mold design, and the extrusion wheel has a high speed.

2. The mechanical shoe locking system of High Speed Extrusion machine is highly reliable, stable and energy-saving.

3. Continuous Extruder adopts an automatic short-bar feeding system to save labor.

4. The constant tension winding system of Continuous Extruder can ensure the stability of product size.

5. The automatic crawler traction machine of Continuous Extruder makes it convenient for operators to replace the spool.

6. The integrated hydraulic system of Continuous Extruder saves space and has no oil leakage.

7. The aviation plug of Continuous Extruder is used for cable connection, which is convenient for cable connection.

8. The industrial cloud data system and production date of Continuous Extruder are traceable.

Our advantages: advanced manufacturing, scientific management and service.

Our products such as High Speed Conform Machine adopt advanced processing methods and strict processing technology to ensure the excellent quality and long-lasting service life of Konform equipment. Products such as Copper Rod Conform Machine are fully debugged before leaving the factory, and will never bring any defects to customers.

We have established a strict supply chain management system: raw materials and supporting components are provided by well-known domestic and foreign companies, and electrical components of products such as Copper Extrusion Equipment are all first-class domestic and foreign brands.

We have a strong after-sales service team (about 30 mechanical and electrical engineers) who have rich professional knowledge and practical experience to provide commissioning, maintenance and repair services to customers all over the world. They can reach the customer factory in a very short time, and if necessary, we can provide 24-hour online support or remote control.