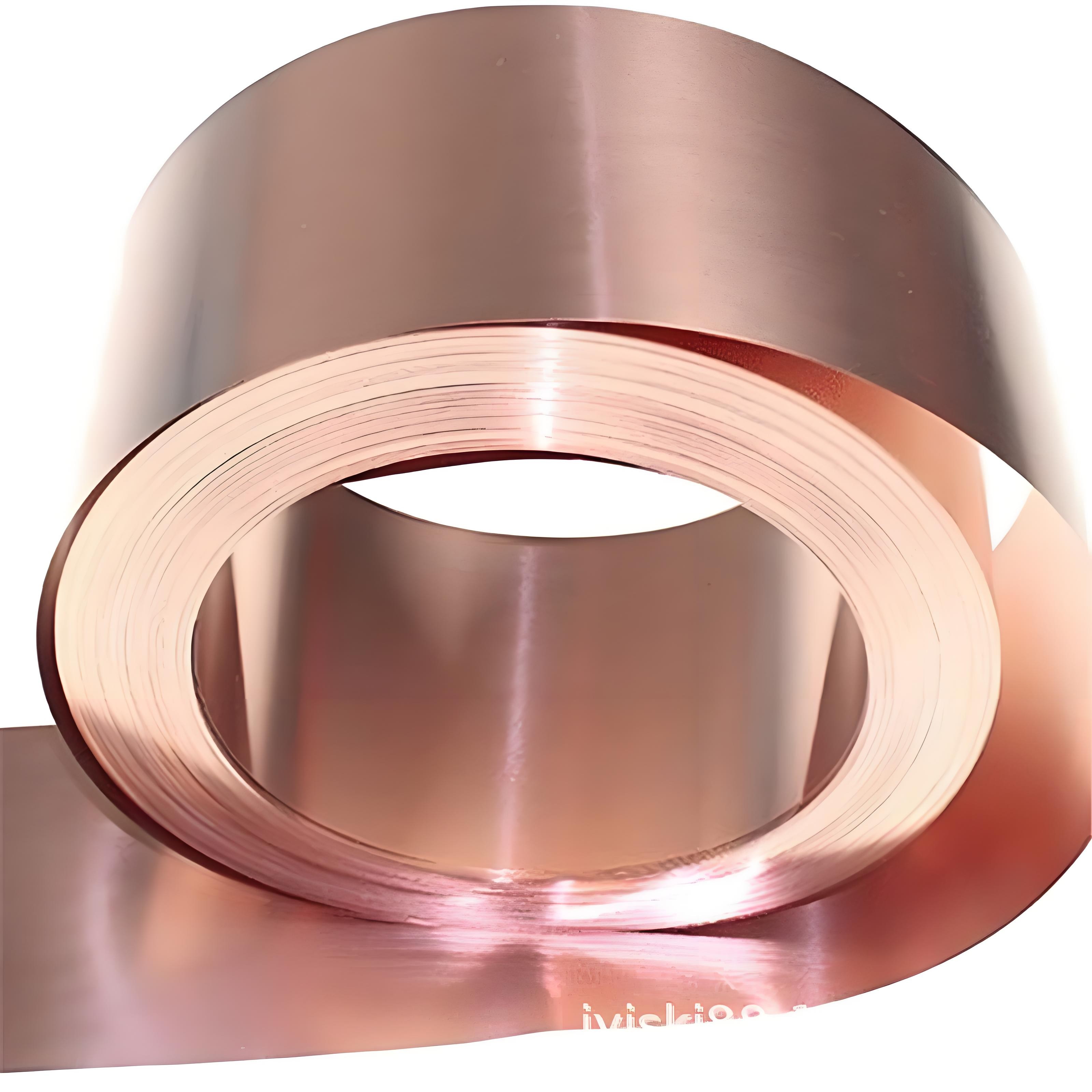

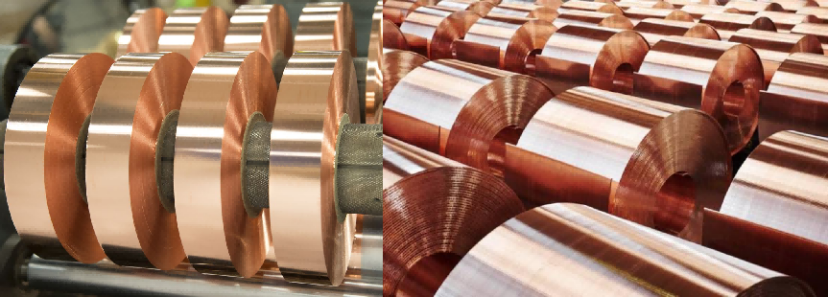

Purpose of extrusion machine for copper strip:

The production process of extrusion machine for copper strip is simple, and the mold can be directly formed. And extrusion die for conform machine does not need to match the mold, and it is easy to replace. Extrusion machine for copper strip has a wide range of applications.Extrusion die for conform machine is mainly used to produce copper bars, copper rods, and profiles of various specifications.

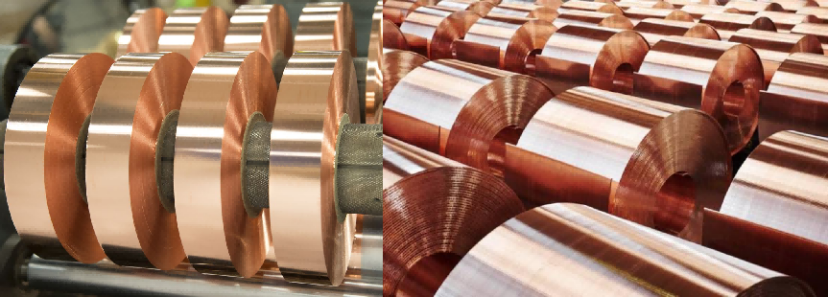

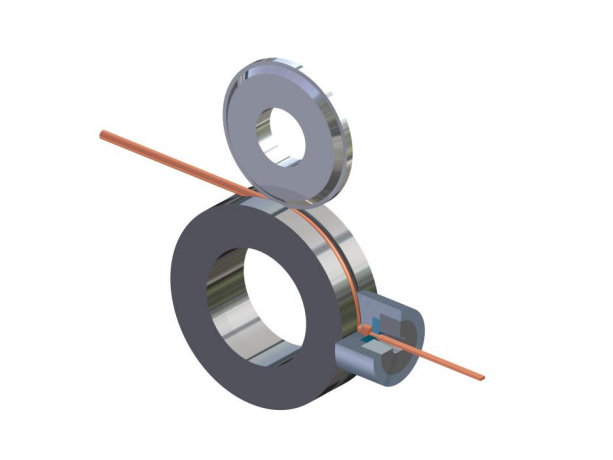

Schematic diagram of continuous extrusion principle:

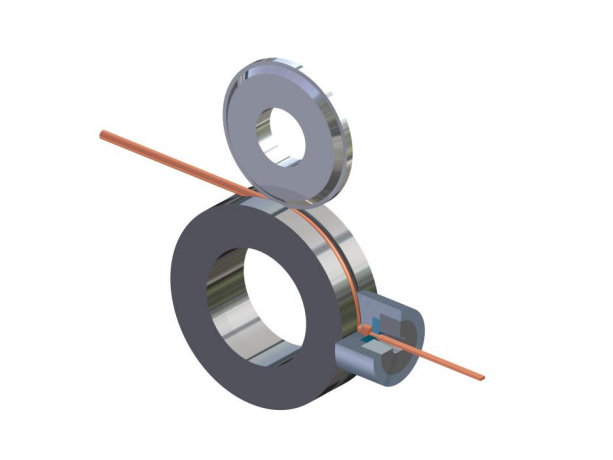

Specifications of extrusion machine for copper strip:

| Model | TLJ630 | TLJ630U |

| Nominal diameter of extrusion wheel (mm) | 630 | 630 |

| Main motor power (kW) | 600 | 600 |

| Diameter of copper rod (mm) | 30 | 30 |

| Maximum width of product (mm) | 320 | 420 |

| Diameter of round rod product (mm)/Maximum aspect ratio (b/a) | 12~120 | 35 |

| Product cross-sectional area (mm2)/Copper strip thickness (mm) | 600~6400 | 14~18 |

| Productivity (kg/h) | 2800 | 3500 |

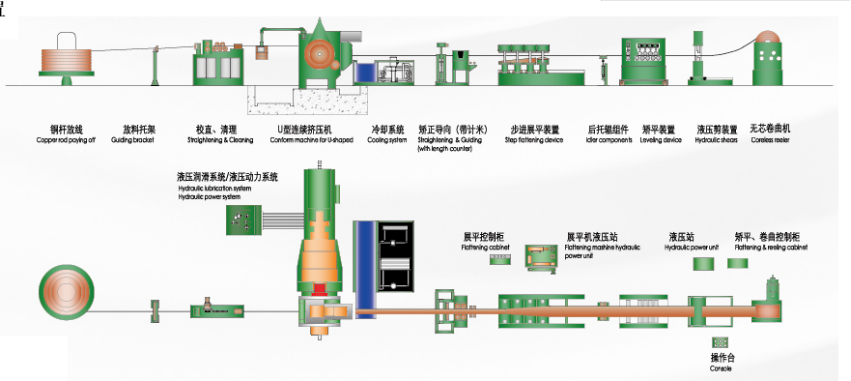

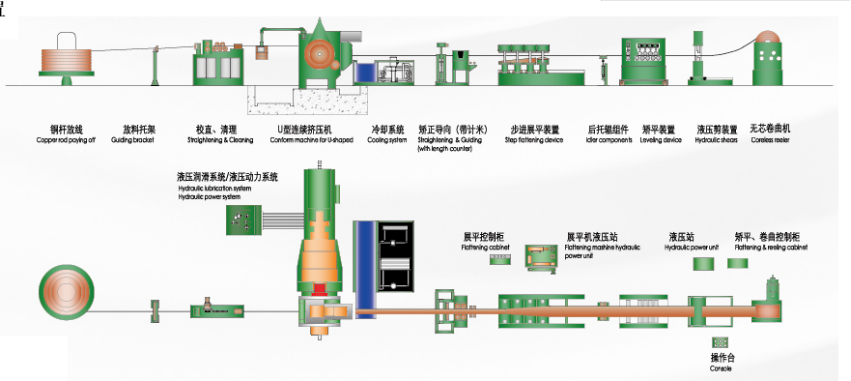

Production line layout of extrusion machine for copper strip

Konform manufacturing:

We are serious and rigorous in the process of manufacturing products such as Copper strip rotary forming machine. The production process of products such as Rotary conform machine adopts the latest manufacturing machinery from world-renowned brands and purchases high-quality raw materials and parts from domestic and foreign sources. The materials and components of rotary conform machine meet our strict internal quality standards. And our copper strip rotary forming machine has also passed the ISO 9001:2008 certified quality management system. The entire production process of Rotary conform machine is carried out in-house, and quality checks are also carried out at each stage of the production of extrusion die for conform machine to ensure the product quality of Copper strip rotary forming machine. With the support of an ERP system that integrates sales, R&D, manufacturing, procurement and logistics, we are able to significantly shorten the manufacturing cycle of copper strip rotary forming machine. By changing from "order design" to "order configuration", we can now respond to customers' diverse needs for copper strip rotary forming machine in a timely manner and deliver orders quickly.

Advantages of extruding copper wire:

1. We have a world-leading industry position, and the sales of products such as extruding copper wire account for 50% of the global total sales of the continuous extrusion industry.

2. Our rotary conform machine saves about 10% energy without reducing production capacity; the extrusion die is mechanically locked to ensure stable extrusion conditions; the gearbox brand and electrical control system are upgraded to monitor production conditions, and remote modules are added for maintenance. All data monitoring and remote maintenance support.

3. The new model equipment of Rotary conform machine saves 20% energy per ton compared with traditional models, increases output by 80%, and saves 60% of space. Rotary conform machine is not only high in precision, but also has a long service life.

4. We have an independent R&D team. The machine is improved and developed every year. And we also have an independent laboratory to test products such as extruding copper wire on site according to special materials provided by customers.

5.All electrical components of products such as extruding copper wire are world famous brands, such as Siemens and ABB.

6. After-sales service for rotary conform machine and other products: 30 maintenance engineers frequently travel around the world to carry out installation and maintenance of products such as extrusion die for conform machine. They can reach the customer's factory in a very short time to provide 24-hour online support or remote control of products such as Rotary conform machine.

Our technical support:

Customer needs are our service content. We attach great importance to the pre-sales service of products such as Extrusion Die for Conform Machine, and strive to achieve personalized customization of products such as extruding copper wire, so as to meet customers' needs of using continuous extrusion technology to extrude new materials and produce new products such as extruding copper wire. To this end, Kangfeng R&D Center is equipped with a full set of 250~630 test equipment, which can carry out process tests of products such as extruding copper wire in advance according to customer requirements, so that customers can eliminate doubts and start new projects with peace of mind. In addition, we have a high-quality after-sales service team with rich professional knowledge and practical experience, providing customers with technical consultation on products such as extruding copper wire around the clock, and solving various problems of customers on site.