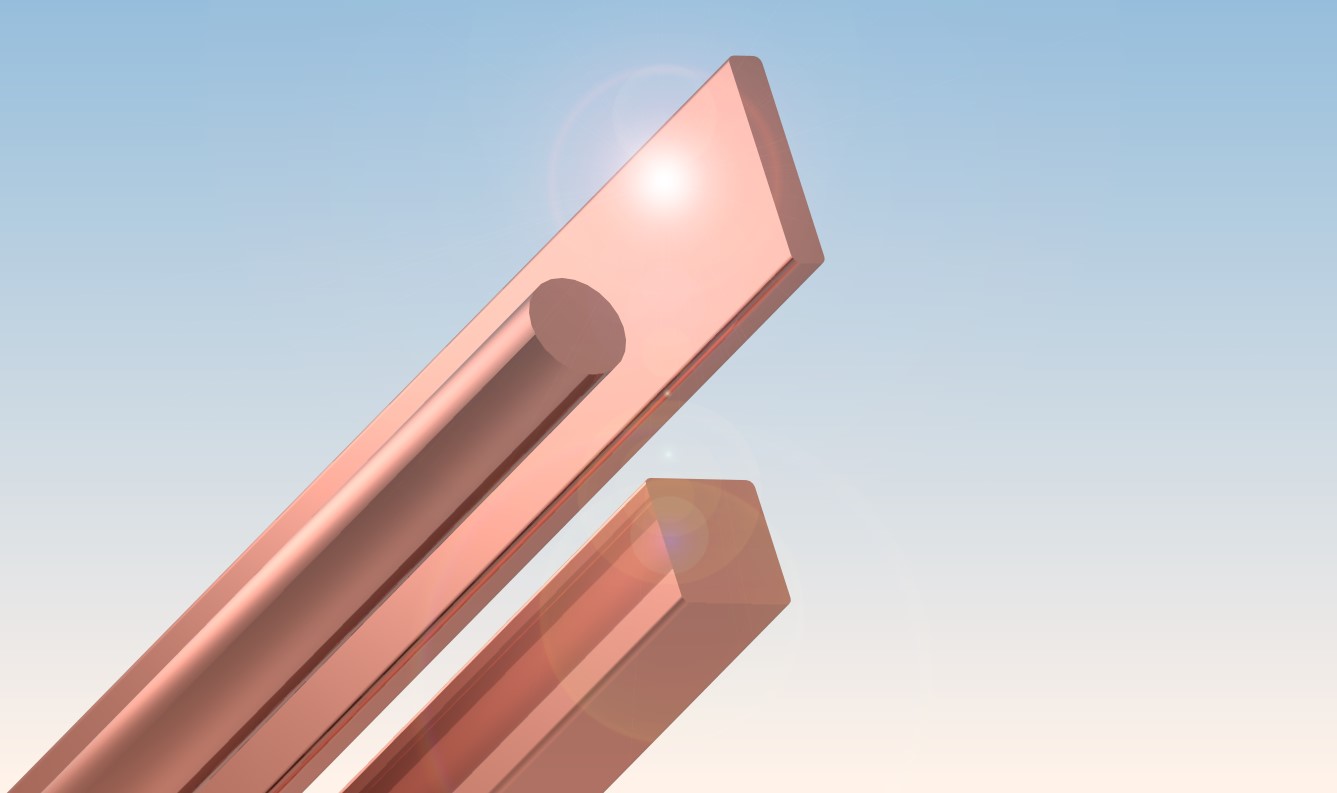

Main uses of Continuous Extrusion Machine for Copper Wire:

Copper Wire Continuous Extrusion Machine can produce copper flat wire, small copper busbar, commutator ladder, round wire and other copper conductors

Specifications of Continuous Extrusion Machine for Copper Wire:

| Model | TLJ300H | TLJ350H |

| Nominal diameter of extrusion wheel(mm) | 300 | 350 |

| Main motor power(kw) | 110 | 160 |

| Copper rod diameter(mm) | 12.5 | 16 |

| Maximum width of flat wire products(mm) | 30 | 100 |

| Minimum diameter of round product(mm) | 2.6 | 4.5 |

| Cross-sectional area of flat wire products(mm2) | 5~150 | 15~1000 |

| Efficiency(kg/h) | 800 | 950 |

Main uses of the Continuous Extrusion Machine for Copper Wire:

Production of copper flat wires, small copper busbars, commutator ladders, round wires and other copper conductors

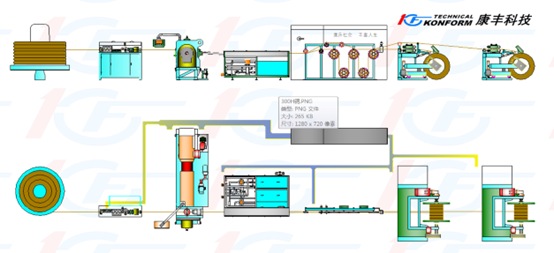

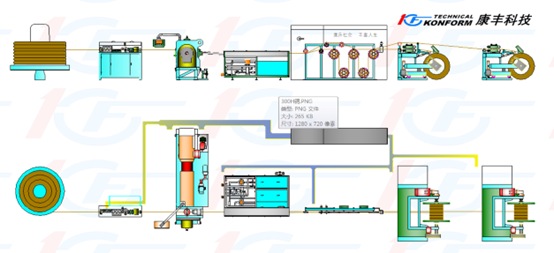

TLJ300H High Speed Copper Extrusion Machine Feature:

High Speed Copper Extrusion Machine is equipped with an advanced cooling mechanism, optimized die configuration, and operates at a faster extrusion wheel speed to boost performance.

Mechanical shoe lock system offers dependable performance, enhances operational consistency, and contributes to lower energy consumption.

Automatic short rod feeding system significantly reduces manual labor and increases workflow efficiency.

Constant tension take-up system plays a key role in keeping product dimensions uniform and stable throughout production.

Automatic caterpillar tractor of Copper Wire Continuous Extrusion Machine simplifies the bobbin replacement process, making it easier for the operator to manage.

High Speed Copper Extrusion Machine integrates a compact hydraulic unit that reduces floor space usage and prevents oil seepage.

Aviation plugs are used for electrical wiring, simplifying connection tasks and improving maintenance efficiency.

Continuous Extrusion Machine for Copper Wire with Industrial cloud data system makes production records transparent, ensuring traceability and process monitoring.

The advantage compare with standard model:

1. High efficiency:2-3times production capacity than traditional machine

2. Energy saving:20% above

3. Operator saving:One person or two person operate 4-5 lines

4. Space saving:60%

5. High performance:increase extrusion wheel life improve the product quality

6. No bubble:No bubble on the surface, good quality.

7. No scratch:traverse is good, no scratch, take up doesn't need to padded paper

8. Reliable:safe, reliable and low failure rate

9. Internet:lay the foundation for intelligent plant, real time monitoring running status and production data

10. Service:remote failure solving

11. Environmental protection:Noise less than82dB, no oil & water leakage

Konform service:

Customer service is not only the first point of connection for many clients but often the last impression they remember. It plays an essential role in fostering customer confidence and establishing long-term cooperation. When users face technical issues or have inquiries, responsive and professional support from customer service representatives helps ease their worries and reflects the company's dedication to customer satisfaction.

We have a professional after-sales service team composed of around 30 skilled mechanical and electrical engineers, all with solid expertise and hands-on experience. They are capable of reaching the customer's site in a short time when on-site assistance is required. For urgent or remote cases, we also offer 24/7 online technical support or remote troubleshooting to ensure timely problem-solving, no matter where our customers are located.