Main uses of high speed continuous extrusion machine for copper wire:

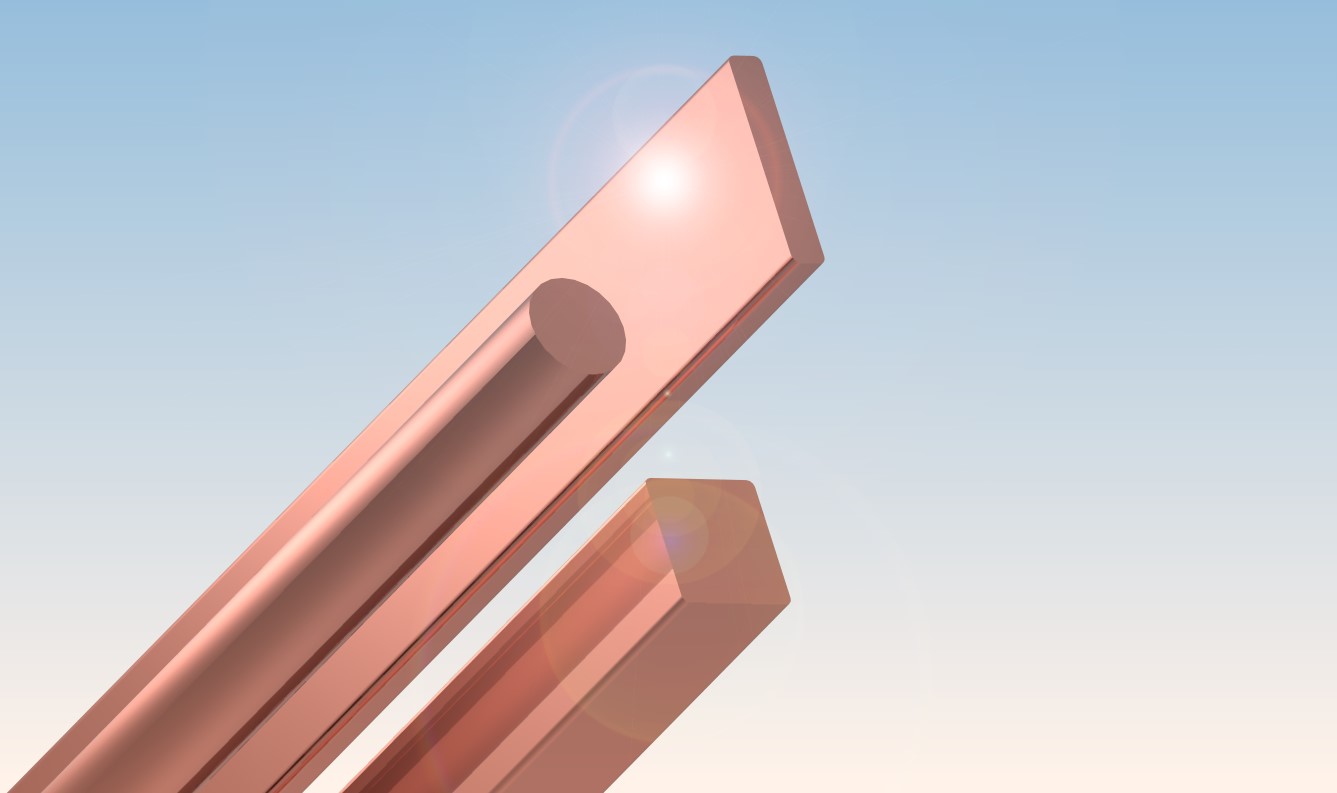

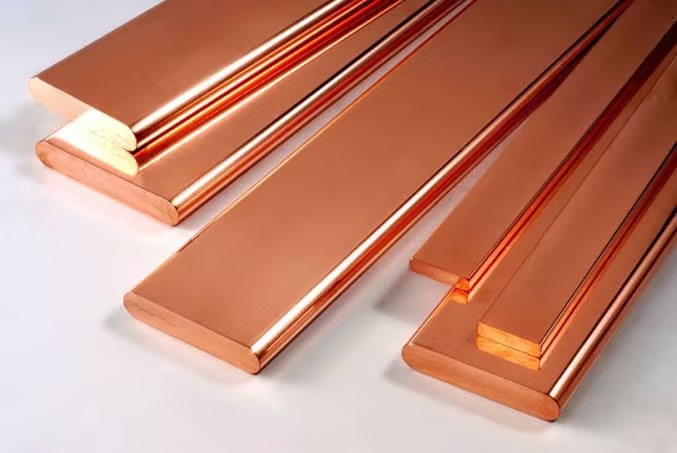

Can produce copper flat wire, small copper bus, commutator ladder, round wire and other copper conductors.

Specifications of Continuous Extrusion Machine for Magnet Wire:

Model | TLJ300H | TLJ350H |

Nominal diameter of extrusion wheel(mm) | 300 | 350 |

Main motor power(kw) | 110 | 200 |

Copper rod diameter(mm) | 12.5 | 16 |

Maximum width of flat wire products(mm) | 30 | 100 |

Minimum diameter of round product(mm) | 2.6 | 4.5~50 |

Cross-sectional area of flat wire products(mm2) | 5~150 | 15~1000 |

Efficiency(kg/h) | 900 | 950 |

The Principle of high speed continuous extrusion machine for copper wire:

The metal rod material is dragged into the continuously rotating extrusion wheel under the friction force of the wheel groove of High Speed Continuous Extrusion Machine. When it reaches abutment, the rod material is forced to change direction and enter the chamber from the radial direction. With the high temperature and pressure caused by friction and deformation reaching the plastic deformation condition, the material is extruded from the die opening to form solid or hollow section products.

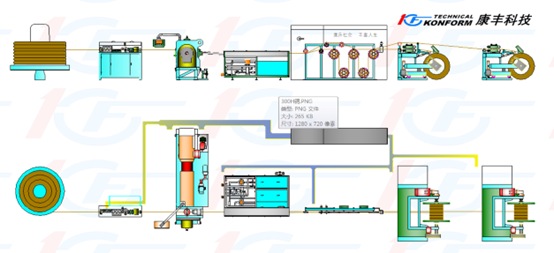

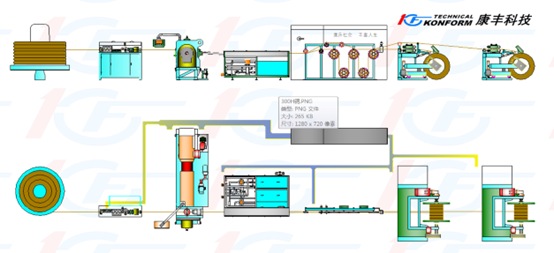

Production line layout of Continuous Extrusion Machine for Magnet Wire:

The advantage compare with standard model.

High efficiency:2-3times production capacity than traditional machine

Energy saving:20% above

Operator saving:One person or two person operate 4-5 lines

Space saving:60%

High performance:Continuous Extrusion Machine for Magnet Wire increase extrusion wheel life, improve the product quality

No bubble:No bubble on the Extursion Machine for Copper Falt Wire surface, good quality.

No scratch:traverse is good, no scratch, take up doesn't need to padded paper

Reliable:safe, reliable and low failure rate

Internet:lay the foundation for intelligent plant, real time monitoring running status and production data

Service:remote failure solving

Environmental protection:Noise less than82dB, no oil & water leakage

Konform Service

Customer service is often the first interaction customers have with a company—and also the last impression they take away. It plays a crucial role in building customer confidence and sustaining long-term partnerships. When clients face issues or have inquiries, timely and effective support from our service team helps ease their worries and shows that we genuinely care about their experience.

We pay great attention to customer needs by equipping our service department with 25 dedicated engineers who specialize in machine installation and on-site debugging. We offer practical technical guidance and solutions while maintaining open communication with clients, enabling them to move forward with their orders without hesitation.

We have a reliable after-sales service team made up of experienced professionals with hands-on knowledge, ready to provide equipment setup, troubleshooting, and repair services worldwide. Additionally, we support our global customers 24/7 through technical consultations via email or virtual meetings, ensuring continuous assistance whenever it's needed.